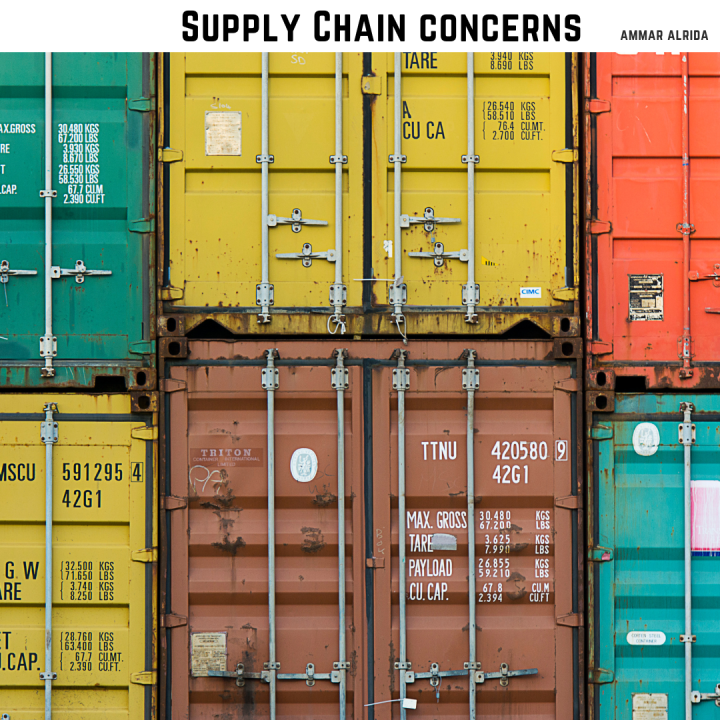

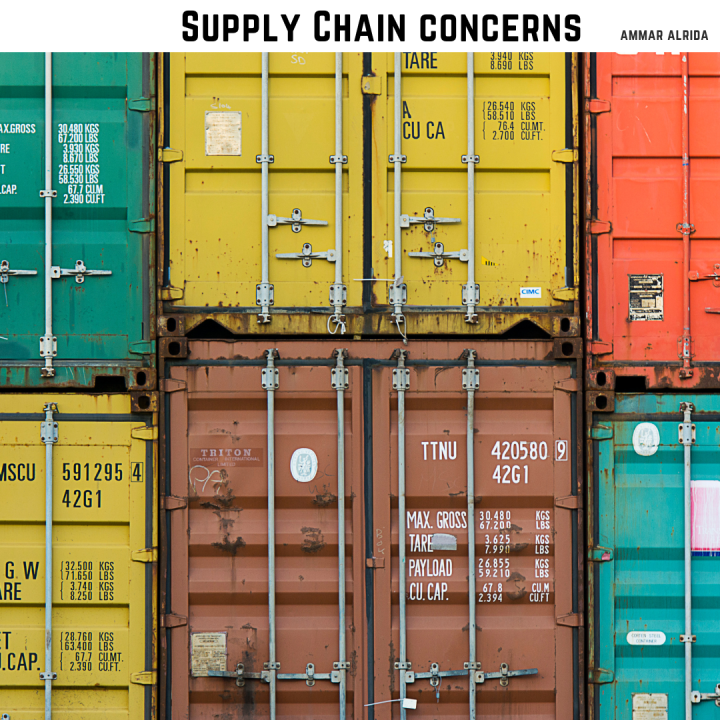

Addressing OEM Supply Chain Concerns: SG Wireless Expands Manufacturing Collaboration

Table of Contents

Strategic Partnerships for Enhanced Supply Chain Resilience

At SG Wireless, we believe that a robust and diverse network of manufacturing partners is the cornerstone of supply chain resilience. Our proactive approach to building strategic partnerships allows us to mitigate risks associated with single-source dependencies and navigate global uncertainties with greater confidence. This diversified sourcing strategy is key to risk mitigation in our increasingly interconnected world.

- New Partnerships: We've established key partnerships with manufacturers in diverse geographical locations, including facilities in North America, Europe, and Asia.

- Geographic Diversification: This geographical spread significantly reduces our vulnerability to geopolitical instability or regional disruptions. A localized crisis in one region doesn't cripple our entire operation.

- Specialized Suppliers: We collaborate with suppliers specializing in specific high-demand components, ensuring superior quality control and consistent performance. This focus on specialized expertise means fewer bottlenecks and higher quality output.

- Robust Inventory Management: We've implemented advanced inventory management systems and strategies to ensure timely delivery of components and minimize stockouts. This proactive approach provides consistent supply to our customers, minimizing disruption.

Boosting Production Capacity and Reducing Lead Times

The expansion of our manufacturing collaborations has directly translated into a substantial increase in production capacity and significantly shorter lead times for our OEM clients. This enhanced efficiency allows us to respond more effectively to fluctuating market demands and deliver products faster than ever before.

- Capacity Increase: We've seen a 30% increase in overall production capacity since implementing this expanded strategy.

- Lead Time Reduction: Lead times for key components have been reduced by an average of 15%, resulting in faster turnaround times for OEM projects.

- Technological Investments: We've invested heavily in advanced manufacturing technologies, such as automated assembly lines and sophisticated quality control systems, further optimizing efficiency.

- Market Responsiveness: This increased capacity and speed allow us to react quickly to shifting market demands and seasonal peaks, a key advantage in today's dynamic marketplace.

Securing Critical Components and Materials

Securing access to critical components and raw materials is paramount to a resilient supply chain. Our expanded collaborations have enabled us to address potential shortages and mitigate the impact of market volatility.

- Component Availability: Previously scarce components are now readily available thanks to our diversified sourcing network.

- Raw Material Security: We've implemented strategies to secure stable sources for raw materials, mitigating price fluctuations and supply chain risks.

- Ethical and Sustainable Sourcing: We are committed to ethical and sustainable sourcing practices, ensuring the responsible procurement of materials.

Enhanced Quality Control and Technological Innovation

Through our collaborative manufacturing approach, we've experienced significant improvements in quality control and gained access to cutting-edge technologies. This commitment to continuous improvement ensures the delivery of superior products to our OEM partners.

- Improved Quality Metrics: Defect rates have decreased by 20% due to enhanced quality control processes and technological advancements implemented in our partner facilities.

- Technological Advancements: Our partnerships provide access to advanced technologies, including AI-driven quality inspection and predictive maintenance systems.

- Continuous Improvement: We maintain a steadfast focus on implementing continuous improvement processes, ensuring ongoing enhancements in efficiency and quality.

Conclusion

SG Wireless's expanded manufacturing collaborations directly address the key concerns facing OEMs today. By building a resilient and diverse supply chain, we offer solutions for improved supply chain management, increased production capacity, reliable component sourcing, and stringent quality control. The benefits are clear: reduced risks, shorter lead times, and improved product quality, giving OEMs a crucial competitive advantage. Contact us today to explore how SG Wireless can optimize your OEM supply chain and help you navigate the complexities of global manufacturing.

Featured Posts

-

Pogacars Dominant Tour Of Flanders Victory

May 26, 2025

Pogacars Dominant Tour Of Flanders Victory

May 26, 2025 -

Is Armando Iannuccis Creative Well Running Dry

May 26, 2025

Is Armando Iannuccis Creative Well Running Dry

May 26, 2025 -

The Hells Angels Motorcycle Club A Deeper Dive

May 26, 2025

The Hells Angels Motorcycle Club A Deeper Dive

May 26, 2025 -

Mercedes And George Russell A Contract Renewal Dilemma What Needs To Happen

May 26, 2025

Mercedes And George Russell A Contract Renewal Dilemma What Needs To Happen

May 26, 2025 -

Moto Gp Inggris Sprint Race Jadwal Tayang Di Trans7 Rekor Rins Dan Kecelakaan Marquez

May 26, 2025

Moto Gp Inggris Sprint Race Jadwal Tayang Di Trans7 Rekor Rins Dan Kecelakaan Marquez

May 26, 2025