American Manufacturing: A Look At The Difficulties

Table of Contents

High Labor Costs and Competition from Overseas

One of the most significant hurdles facing American manufacturing is the high cost of labor compared to many other countries. This significantly impacts the competitiveness of US-made goods in the global marketplace.

Wages and Benefits

- Higher Minimum Wages: The US minimum wage, while varying by state, is generally higher than in many competing nations, directly impacting production costs.

- Comprehensive Benefits Packages: American companies often provide extensive benefits packages including health insurance, retirement plans, and paid time off, adding to overall labor expenses.

- Unionization: Unionized workplaces frequently command higher wages and benefits than non-unionized settings, further increasing labor costs for some manufacturers.

These factors contribute to a higher cost of production per unit compared to countries with lower wages and less comprehensive benefits. This price difference makes it difficult for American manufacturers to compete on price alone, especially against goods produced in countries like China or Vietnam.

Global Competition

The intense competition from countries with significantly lower labor costs presents a substantial challenge. This global competition is particularly acute in industries like:

- Textiles: The US textile industry has been significantly impacted by cheaper imports from countries with lower labor costs and less stringent regulations.

- Electronics: The manufacturing of many electronic goods has shifted to countries like China and South Korea, where labor is cheaper and supply chains are well-established.

Trade agreements and tariffs play a significant role in shaping this competitive landscape. While some agreements aim to foster free trade, others impose tariffs to protect domestic industries from foreign competition. American manufacturers are employing various strategies to mitigate these challenges, including focusing on niche markets requiring higher skill levels and greater innovation, as well as increased investment in automation and advanced manufacturing technologies.

Supply Chain Disruptions and Logistics Challenges

Navigating the complexities of global supply chains has become increasingly difficult for American manufacturers. Disruptions and logistical bottlenecks add to costs and hinder production.

Raw Material Shortages

Sourcing raw materials presents a significant challenge, with many manufacturers facing:

- Rising Prices: The cost of raw materials, such as steel, lumber, and semiconductors, has experienced significant increases in recent years, impacting profitability.

- Unpredictable Supply: Geopolitical instability, natural disasters, and pandemics have disrupted supply chains, leading to unpredictable availability of crucial raw materials.

Manufacturers are actively seeking strategies to mitigate these risks, including diversifying their sourcing and establishing closer relationships with suppliers. Investing in strategic stockpiling and developing alternative materials are also being explored.

Transportation Costs and Delays

Transportation costs and delays further complicate the supply chain. Factors contributing to these challenges include:

- Rising Fuel Prices: Fluctuations in fuel prices directly impact the cost of transporting goods, adding to overall expenses.

- Port Congestion: Congestion at major ports leads to delays and increased storage costs, impacting the timely delivery of materials and finished goods.

- Driver Shortages: A shortage of truck drivers exacerbates logistical challenges, leading to delays and increased transportation costs.

Investing in infrastructure improvements, such as upgrading ports and expanding transportation networks, is crucial to alleviate these bottlenecks. The adoption of advanced logistics software and optimization techniques can also enhance efficiency and reduce delays.

Automation and Technological Advancement

The adoption of automation technologies presents both opportunities and challenges for American manufacturing.

Investment in Automation

While automation can boost productivity and efficiency, the initial investment costs can be substantial:

- Robotics: Integrating robotic systems into manufacturing processes requires significant upfront investment in equipment and skilled labor.

- Artificial Intelligence (AI): AI-powered systems offer significant potential for optimizing processes, but require expertise to implement and maintain.

The return on investment (ROI) from automation varies depending on the specific technology and industry. Manufacturers need to carefully assess the costs and benefits before making significant investments. Successful automation strategies require a holistic approach, integrating new technologies into existing processes and workflows efficiently.

Skills Gap and Workforce Training

The increasing reliance on advanced manufacturing technologies highlights the need for a highly skilled workforce:

- Specialized Skills: Operating and maintaining sophisticated equipment requires specialized skills and training that are often in short supply.

- Upskilling and Reskilling: Existing workers may need upskilling or reskilling to adapt to new technologies and processes.

Addressing the skills gap requires a concerted effort from educational institutions, industry, and government to invest in training programs and apprenticeships that equip workers with the necessary skills for advanced manufacturing jobs.

Regulatory Compliance and Environmental Concerns

Meeting regulatory requirements adds another layer of complexity and cost to American manufacturing.

Environmental Regulations

Complying with increasingly stringent environmental regulations is crucial but can impact profitability:

- Emission Standards: Meeting emission standards for air and water pollutants requires investment in pollution control technologies.

- Waste Disposal: Properly managing and disposing of manufacturing waste adds to operational costs.

Balancing environmental responsibility with profitability is a key challenge for manufacturers. Investing in sustainable manufacturing practices and technologies can both reduce environmental impact and enhance a company’s image and appeal to environmentally-conscious consumers.

Safety and Health Regulations

Adhering to workplace safety and health regulations is paramount, but entails significant costs:

- Safety Equipment: Investing in safety equipment and training programs is essential to ensure a safe work environment.

- Compliance Audits: Regular safety audits and compliance checks are necessary to meet regulatory requirements.

Prioritizing workplace safety not only complies with regulations but also fosters a more productive and positive work environment, reducing accidents and associated costs.

Conclusion

The challenges facing American manufacturing are multifaceted and substantial. High labor costs, global competition, supply chain disruptions, technological advancements, and regulatory compliance all contribute to a complex operating environment. However, overcoming these difficulties is achievable through a strategic and proactive approach. This requires significant investment in automation and advanced manufacturing technologies, coupled with robust workforce development initiatives to bridge the skills gap. Improving infrastructure, diversifying supply chains, and fostering a culture of innovation are also key elements. Supporting American manufacturing is not just about bolstering a specific sector, it's about safeguarding the future of the US economy. Investing in and revitalizing American manufacturing is a crucial step towards ensuring continued economic strength and prosperity.

Featured Posts

-

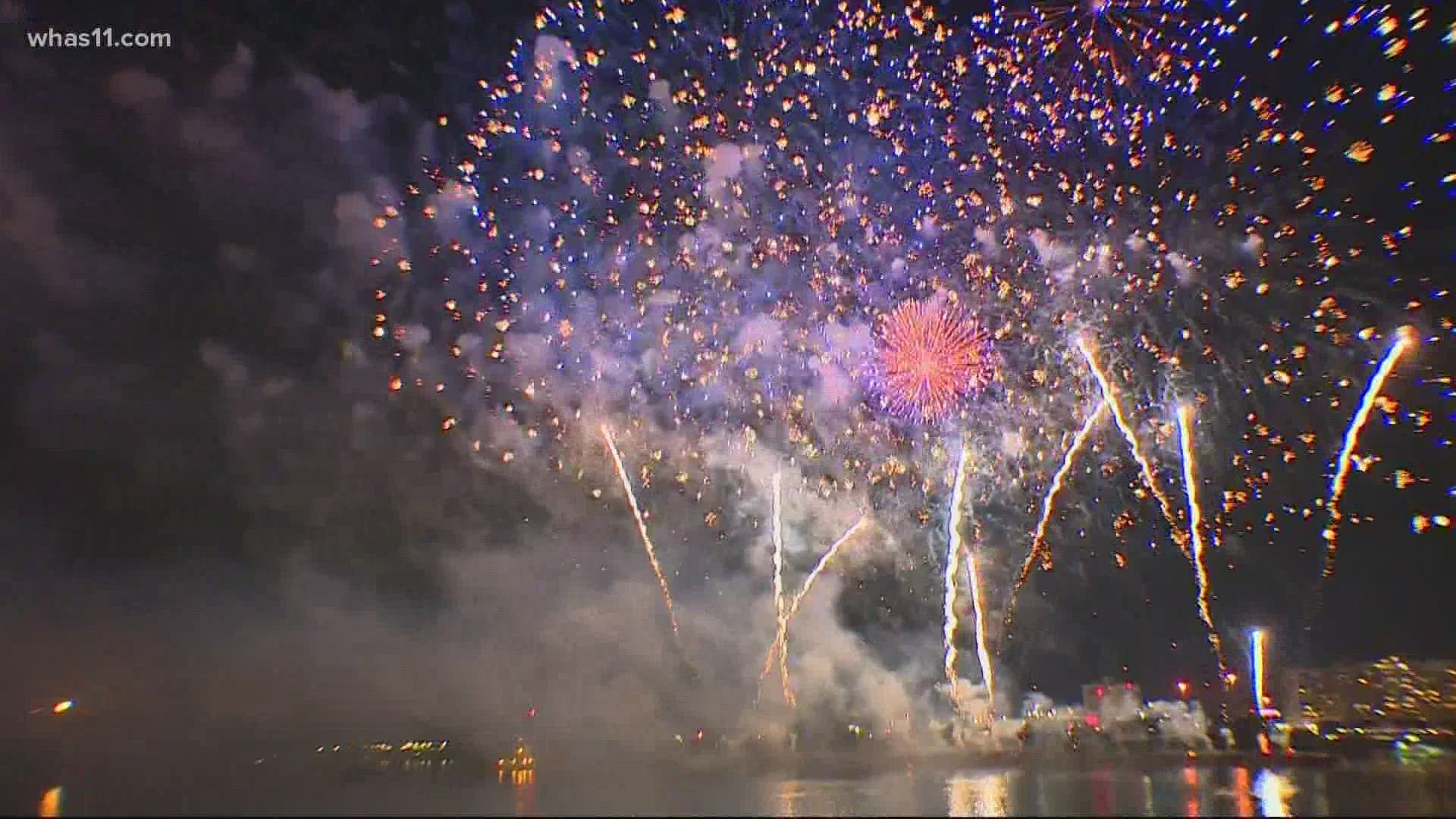

Thunder Over Louisville Fireworks Canceled Ohio River Flooding

Apr 29, 2025

Thunder Over Louisville Fireworks Canceled Ohio River Flooding

Apr 29, 2025 -

Trumps Transgender Athlete Ban Us Attorney General Issues Warning To Minnesota

Apr 29, 2025

Trumps Transgender Athlete Ban Us Attorney General Issues Warning To Minnesota

Apr 29, 2025 -

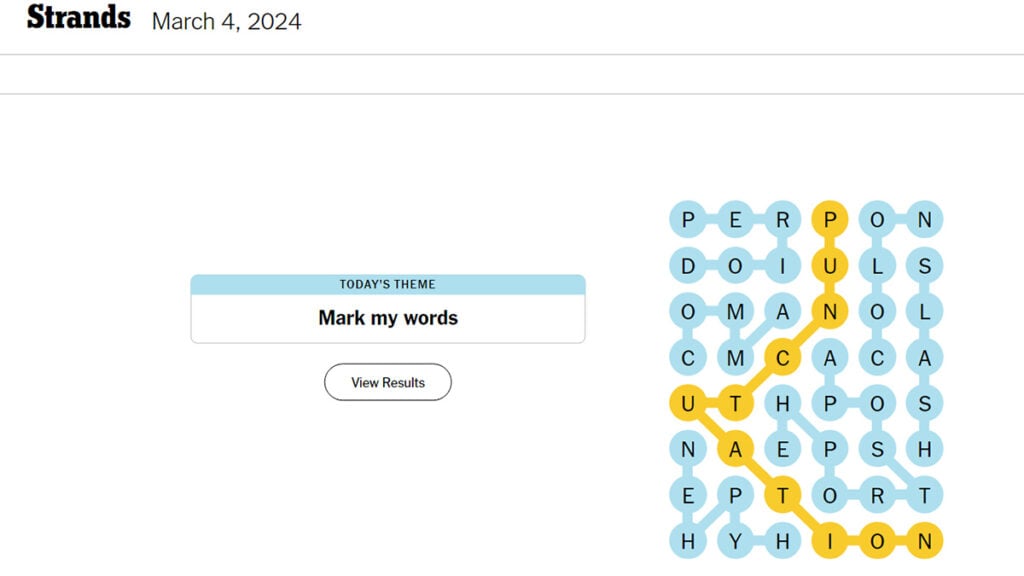

Nyt Strands Hints And Answers Monday March 31 Game 393

Apr 29, 2025

Nyt Strands Hints And Answers Monday March 31 Game 393

Apr 29, 2025 -

Higher Earning Trends Among Minnesota Immigrants A Recent Study

Apr 29, 2025

Higher Earning Trends Among Minnesota Immigrants A Recent Study

Apr 29, 2025 -

Shedeur Sanders Prank Call Son Of Falcons Defensive Coordinator Apologizes

Apr 29, 2025

Shedeur Sanders Prank Call Son Of Falcons Defensive Coordinator Apologizes

Apr 29, 2025

Latest Posts

-

Will Trump Pardon Rose A Complete Analysis

Apr 29, 2025

Will Trump Pardon Rose A Complete Analysis

Apr 29, 2025 -

Trump To Issue Full Pardon For Rose Latest Updates

Apr 29, 2025

Trump To Issue Full Pardon For Rose Latest Updates

Apr 29, 2025 -

You Tubes Growing Appeal To Older Viewers Nostalgia And Accessibility

Apr 29, 2025

You Tubes Growing Appeal To Older Viewers Nostalgia And Accessibility

Apr 29, 2025 -

How You Tube Caters To The Preferences Of Older Viewers

Apr 29, 2025

How You Tube Caters To The Preferences Of Older Viewers

Apr 29, 2025 -

You Tube A Platform For Classic Tv Shows And Older Viewers

Apr 29, 2025

You Tube A Platform For Classic Tv Shows And Older Viewers

Apr 29, 2025