Analysis Of Big Rig ROCK Report 3.12 And Laser 101.7 Metrics

Table of Contents

Key Performance Indicators (KPIs) from Big Rig ROCK Report 3.12

Big Rig ROCK Report 3.12 (assuming this refers to a specific fleet management software – adapt as needed) likely provides a comprehensive overview of your fleet’s performance. Let's dissect some key areas:

Fuel Efficiency Analysis

Fuel costs are a significant expense for trucking companies. ROCK Report 3.12 probably tracks fuel consumption meticulously. Key KPIs to focus on include:

- MPG (Miles Per Gallon): A lower MPG indicates areas needing improvement. Analyze trends over time to identify potential problems.

- Fuel Cost Per Mile: This metric directly reflects your operational expenses and allows for cost-benefit analysis of different strategies.

- Idle Time: Excessive idling significantly increases fuel consumption. ROCK Report 3.12 should highlight vehicles with high idle times.

Causes of Fuel Inefficiency:

- Aggressive Driving: Harsh acceleration and braking waste fuel.

- Poor Vehicle Maintenance: Inefficient engines consume more fuel.

- Suboptimal Routing: Poor route planning leads to increased mileage.

Strategies for Improvement:

- Driver Training: Implement driver training programs focused on fuel-efficient driving techniques.

- Preventative Maintenance: Adhere to a strict preventative maintenance schedule.

- Route Optimization: Utilize GPS and route planning software to find the most efficient routes.

Driver Performance Metrics

ROCK Report 3.12 likely includes driver behavior data, allowing you to assess driver performance based on various metrics.

- Speeding: Frequent speeding incidents indicate a safety risk and increased fuel consumption.

- Harsh Braking and Acceleration: These actions contribute to wear and tear on the vehicle and fuel inefficiency.

- Idling: Excessive idling negatively impacts fuel economy and contributes to emissions.

Improving Driver Performance:

- Driver Scorecards: Use driver scorecards to provide regular feedback and identify areas for improvement.

- Performance Reviews: Conduct regular performance reviews to discuss driver behavior and address any concerns.

- Incentive Programs: Reward drivers for safe and fuel-efficient driving practices.

Vehicle Maintenance and Repair Analysis

ROCK Report 3.12 should provide insights into vehicle maintenance and repair costs. Analyze:

- Scheduled Maintenance: Ensure adherence to recommended maintenance schedules.

- Unscheduled Repairs: High numbers indicate potential issues with vehicle maintenance or driver behavior.

- Downtime: Minimize downtime by proactive maintenance to maximize vehicle uptime.

Improving Maintenance Practices:

- Predictive Maintenance: Utilize data analysis to predict potential maintenance needs.

- Preventative Maintenance Programs: Implement rigorous preventative maintenance schedules to catch problems early.

- Efficient Repair Processes: Streamline repair processes to minimize downtime.

Critical Metrics from Laser 101.7

Laser 101.7 (again, assuming a specific software – adapt accordingly) likely focuses on real-time tracking and operational efficiency.

Location Tracking and Route Optimization

Laser 101.7's GPS tracking capabilities offer valuable data for route optimization.

- Real-time Location Data: Monitor vehicle locations to ensure timely deliveries.

- Mileage Tracking: Analyze mileage data to identify inefficiencies in routing.

- Traffic and Weather Data Integration: Use real-time traffic and weather data to adjust routes dynamically.

Optimizing Routes:

- Route Planning Software: Invest in route planning software that considers real-time conditions.

- Regular Route Analysis: Periodically review routes and make adjustments based on data analysis.

Delivery Performance and On-Time Delivery Rates

On-time delivery is critical for customer satisfaction and maintaining a strong reputation. Laser 101.7 can help you track:

- On-Time Delivery Rate: Calculate the percentage of deliveries made on time.

- Delivery Delays: Identify common causes of delivery delays.

- Customer Feedback: Collect customer feedback on delivery performance.

Improving On-Time Delivery:

- Improved Communication: Enhance communication between dispatchers, drivers, and customers.

- Proactive Scheduling: Plan deliveries proactively, anticipating potential delays.

Asset Utilization and Productivity

Laser 101.7 likely tracks asset utilization, enabling analysis of:

- Truck Utilization: Calculate the percentage of time trucks are actively engaged in deliveries.

- Driver Utilization: Analyze driver hours and productivity.

- Idle Time: Reduce idle time through efficient route planning and scheduling.

Maximizing Asset Utilization:

- Optimized Scheduling: Implement optimized scheduling to ensure maximum asset utilization.

- Dynamic Routing: Utilize dynamic routing to adapt to changing conditions and optimize schedules in real time.

Conclusion: Optimizing Your Fleet with Big Rig ROCK Report 3.12 and Laser 101.7 Data Analysis

Analyzing the data from Big Rig ROCK Report 3.12 and Laser 101.7 is essential for optimizing your trucking fleet. By carefully examining fuel efficiency, driver performance, vehicle maintenance, route optimization, delivery performance, and asset utilization, you can identify areas for improvement and make data-driven decisions. Continuous monitoring and analysis of these metrics are key to reducing costs, enhancing safety, and increasing overall profitability. Don't let valuable data sit unused. Start leveraging the insights from your Big Rig ROCK Report and Laser 101.7 reports today to improve your fleet management and drive significant improvements to your bottom line. Explore advanced analytics features within your software and consider investing in additional tools to further refine your data analysis for even greater efficiency and profitability.

Featured Posts

-

Zimbabwes Historic Test Victory Edge Past Bangladesh

May 23, 2025

Zimbabwes Historic Test Victory Edge Past Bangladesh

May 23, 2025 -

Panama Vs Mexico Los Memes Que Inundaron Las Redes Sociales Tras La Final

May 23, 2025

Panama Vs Mexico Los Memes Que Inundaron Las Redes Sociales Tras La Final

May 23, 2025 -

Analyzing The New County Season Familiar Teams New Challenges Trophy Hopes

May 23, 2025

Analyzing The New County Season Familiar Teams New Challenges Trophy Hopes

May 23, 2025 -

Two Bishop England Grads Set For Louisvilles 2025 Ncaa Tournament Run

May 23, 2025

Two Bishop England Grads Set For Louisvilles 2025 Ncaa Tournament Run

May 23, 2025 -

The One Percent And The President Clintons Budget Veto Strategy

May 23, 2025

The One Percent And The President Clintons Budget Veto Strategy

May 23, 2025

Latest Posts

-

Witkoffs Claim Duped By Hamas Emissary Reveals Allegations

May 23, 2025

Witkoffs Claim Duped By Hamas Emissary Reveals Allegations

May 23, 2025 -

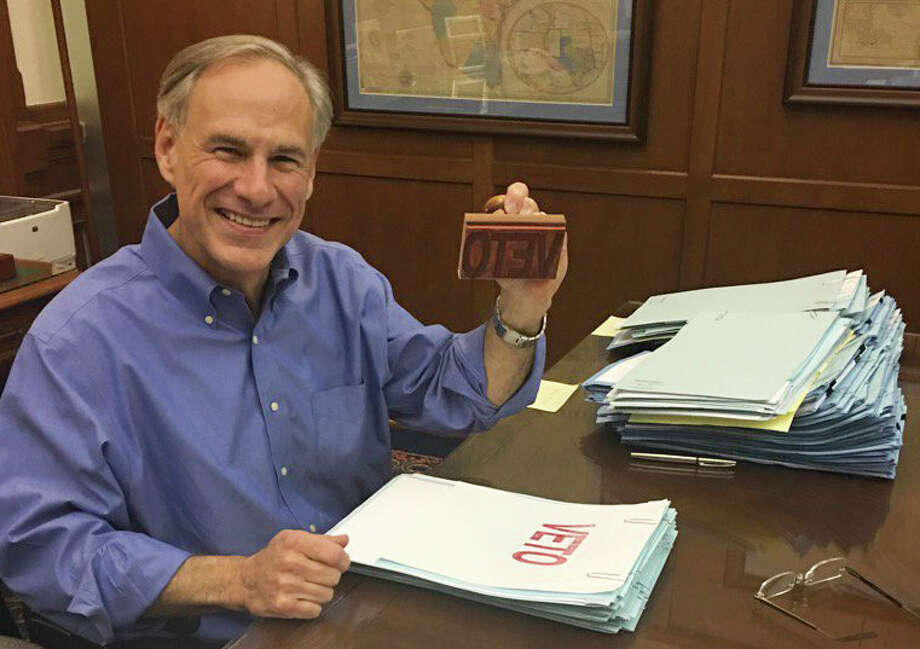

Ooredoo Qatar And Qtspbf Renewed Commitment To Collaboration

May 23, 2025

Ooredoo Qatar And Qtspbf Renewed Commitment To Collaboration

May 23, 2025 -

Extended Partnership Ooredoo Qatar And Qtspbf On Continued Success

May 23, 2025

Extended Partnership Ooredoo Qatar And Qtspbf On Continued Success

May 23, 2025 -

Strengthening Ties Ooredoo Qatar And Qtspbf Extend Collaboration

May 23, 2025

Strengthening Ties Ooredoo Qatar And Qtspbf Extend Collaboration

May 23, 2025 -

Ooredoo And Qtspbf A Winning Partnership Continues

May 23, 2025

Ooredoo And Qtspbf A Winning Partnership Continues

May 23, 2025