Can The US Manufacturing Sector Recover Lost Jobs?

Table of Contents

The Challenges Facing US Manufacturing Job Growth

The road to recovery for US manufacturing jobs is paved with significant hurdles. Addressing these challenges is paramount to achieving sustainable growth and creating a competitive landscape.

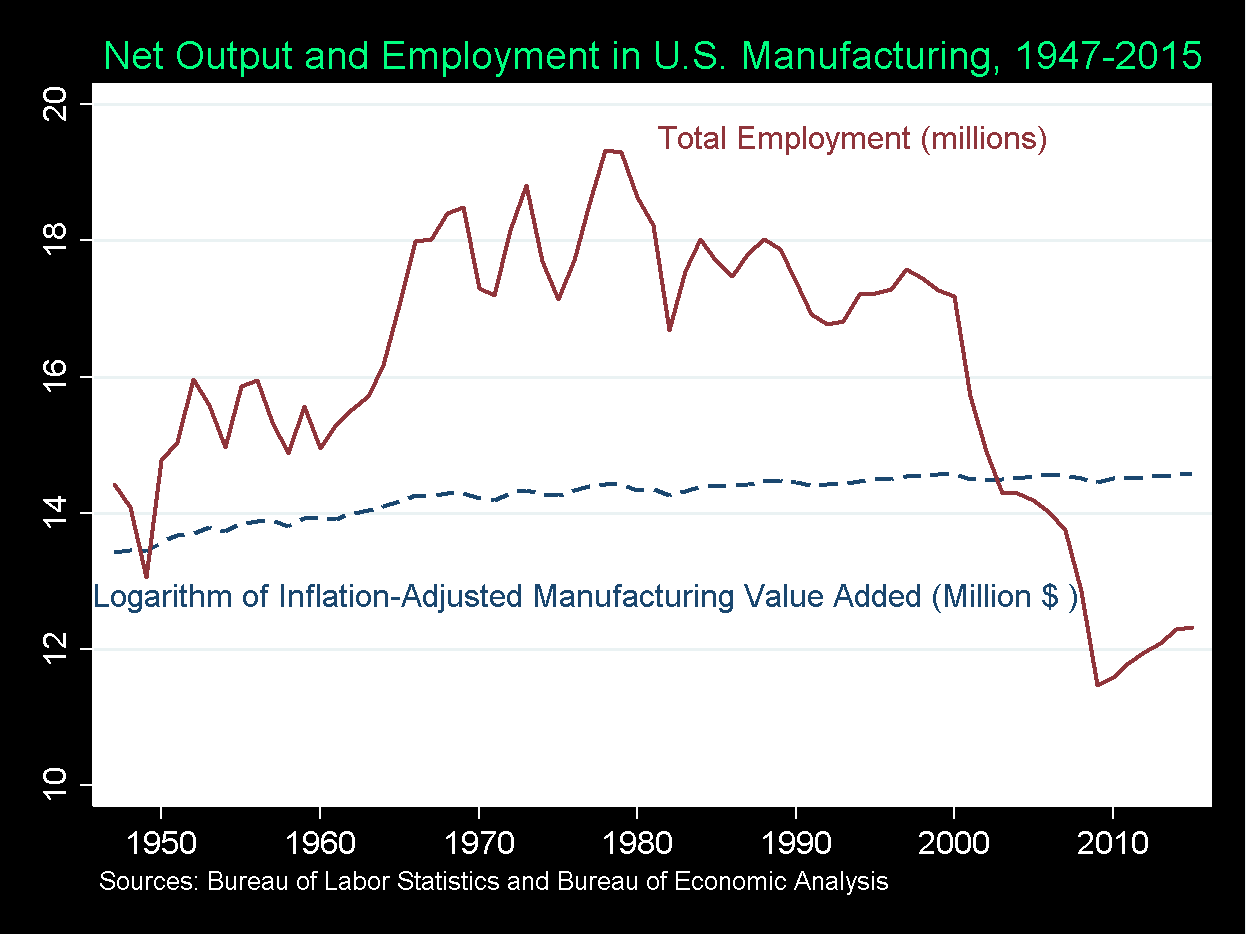

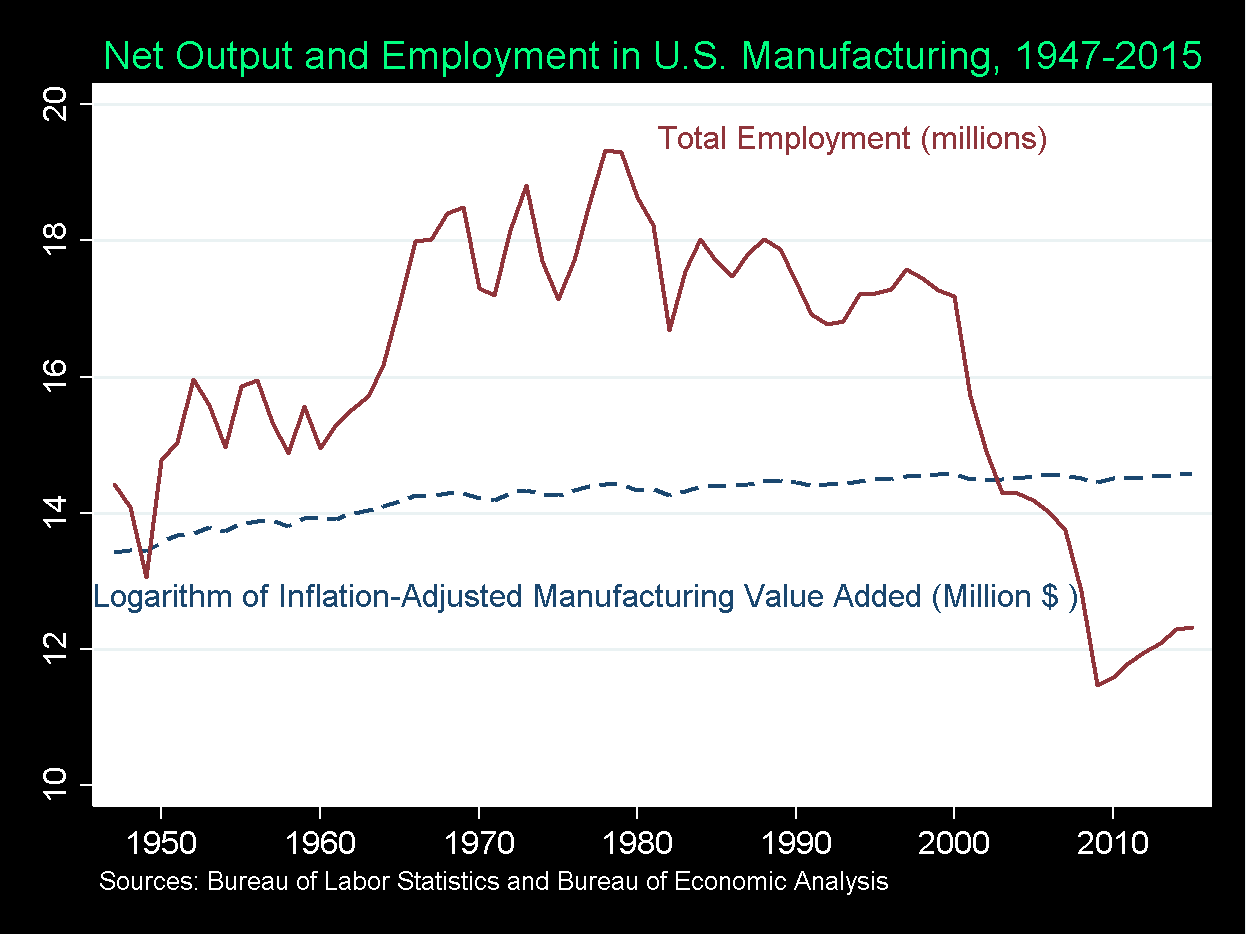

Automation and Technological Advancements

Automation and robotics have revolutionized manufacturing, increasing efficiency and productivity. While this has led to significant gains in output, it has also resulted in job displacement.

- Increased efficiency: Automated systems often require fewer workers to achieve the same or higher levels of production, leading to workforce reductions.

- Upskilling and reskilling: The shift towards automation necessitates a workforce equipped with new skills. Existing employees require retraining in areas like robotics programming, data analytics, and system maintenance.

- New technology-related jobs: While some jobs are lost to automation, new opportunities emerge in areas such as designing, implementing, and maintaining automated systems. These jobs, however, often require higher levels of education and specialized training. This is a key area where investment in education and training programs is crucial. The transition to Industry 4.0 demands a proactive approach to workforce development to avoid exacerbating the skills gap.

Global Competition and Offshoring

Lower labor costs in other countries have driven many US manufacturers to offshore production, leading to significant job losses domestically.

- Lower labor costs: Countries with lower wages and less stringent labor regulations often present a more attractive option for manufacturers seeking to minimize production costs.

- Impact of trade agreements: Trade agreements, while aiming to promote global commerce, can inadvertently contribute to offshoring if they don't adequately protect domestic industries.

- Competing with foreign manufacturers: US manufacturers face stiff competition from companies in countries with lower production costs and potentially less stringent environmental regulations. This makes it challenging to maintain competitiveness and retain jobs domestically.

Lack of Skilled Labor

A significant challenge facing US manufacturing is the skills gap – a shortage of skilled technicians, engineers, and other specialized workers.

- Shortage of skilled workers: Many manufacturing jobs require specialized skills and training, and there is a notable shortage of individuals possessing these qualifications.

- Importance of vocational training and apprenticeships: Investing in robust vocational training programs and apprenticeships is vital to develop a skilled workforce capable of meeting the demands of modern manufacturing.

- Attracting young people: The manufacturing industry needs to attract young people to pursue careers in this sector by highlighting the opportunities for innovation, technological advancements, and good wages in modern manufacturing facilities. Effective outreach and education programs are key to achieving this.

Opportunities for Manufacturing Job Growth

Despite the challenges, significant opportunities exist for the US manufacturing sector to recover lost jobs and experience substantial growth.

Reshoring and Nearshoring

Rising labor costs in other countries, coupled with concerns about supply chain disruptions, are making reshoring (bringing manufacturing back to the US) and nearshoring (moving manufacturing to nearby countries) increasingly attractive options.

- Rising labor costs abroad: Wage increases in countries that were previously favored for low-cost manufacturing are making the US a more competitive option.

- Shorter supply chains: Reshoring and nearshoring offer the benefit of shorter and more reliable supply chains, reducing vulnerability to global disruptions.

- Government incentives: Government incentives and tax breaks can make reshoring and nearshoring more financially appealing for manufacturers. These policies play a significant role in attracting businesses and fostering job creation.

Investing in Innovation and Technology

Investing in advanced manufacturing technologies and fostering innovation is key to creating high-skilled, well-paying jobs.

- Advanced manufacturing technologies: Investing in technologies such as 3D printing, robotics, and AI can enhance productivity, improve quality, and create new job opportunities in areas like automation engineering and data science.

- New products and processes: Innovation in product design and manufacturing processes can lead to the development of new, high-demand products and create new jobs in research and development (R&D) and specialized manufacturing roles.

- High-skilled jobs: A focus on advanced manufacturing creates a demand for skilled workers in areas such as software development, data analytics, and automation engineering. This is in stark contrast to the image of manual labor often associated with manufacturing in the past.

Focusing on Sustainability and Green Manufacturing

The growing demand for sustainable products and government regulations promoting green manufacturing offer significant opportunities for job creation.

- Demand for sustainable products: Consumers are increasingly demanding environmentally friendly products, creating a market for manufacturers specializing in sustainable and eco-friendly production.

- Government regulations: Government regulations promoting green manufacturing practices, such as stricter emission standards, incentivize companies to adopt sustainable technologies and create new jobs in renewable energy and green technology sectors.

- Circular economy: Embracing the principles of a circular economy – focusing on reducing waste, reusing materials, and recycling – can create new economic opportunities and jobs in related fields.

Conclusion

The recovery of US manufacturing jobs presents both challenges and opportunities. While automation and global competition pose significant hurdles, the potential for reshoring, technological innovation, and the growth of green manufacturing offers a path towards a thriving and competitive manufacturing sector. By strategically investing in workforce development, embracing technological advancements, and promoting reshoring initiatives, the US can create a sustainable manufacturing landscape, ultimately leading to the recovery of lost jobs and a stronger national economy. Let's work together to ensure the resurgence of US manufacturing and its vital contribution to our workforce. Learn more about the future of US manufacturing jobs and how you can be a part of this vital economic sector.

Featured Posts

-

Tikkie En Uw Bankrekening Een Praktische Gids

May 21, 2025

Tikkie En Uw Bankrekening Een Praktische Gids

May 21, 2025 -

T Hriskeytiki Esperida Megali Tessarakosti Patriarxiki Akadimia Kritis

May 21, 2025

T Hriskeytiki Esperida Megali Tessarakosti Patriarxiki Akadimia Kritis

May 21, 2025 -

Kcrg Tv 9 10 Minnesota Twins Games On The Air

May 21, 2025

Kcrg Tv 9 10 Minnesota Twins Games On The Air

May 21, 2025 -

Dexter Resurrection De Terugkeer Van Lithgow En Smits

May 21, 2025

Dexter Resurrection De Terugkeer Van Lithgow En Smits

May 21, 2025 -

Patra Efimereyontes Iatroi Savvatokyriako

May 21, 2025

Patra Efimereyontes Iatroi Savvatokyriako

May 21, 2025