Case Study Addendum: BYD's Leadership In Electric Vehicle Battery Manufacturing

Table of Contents

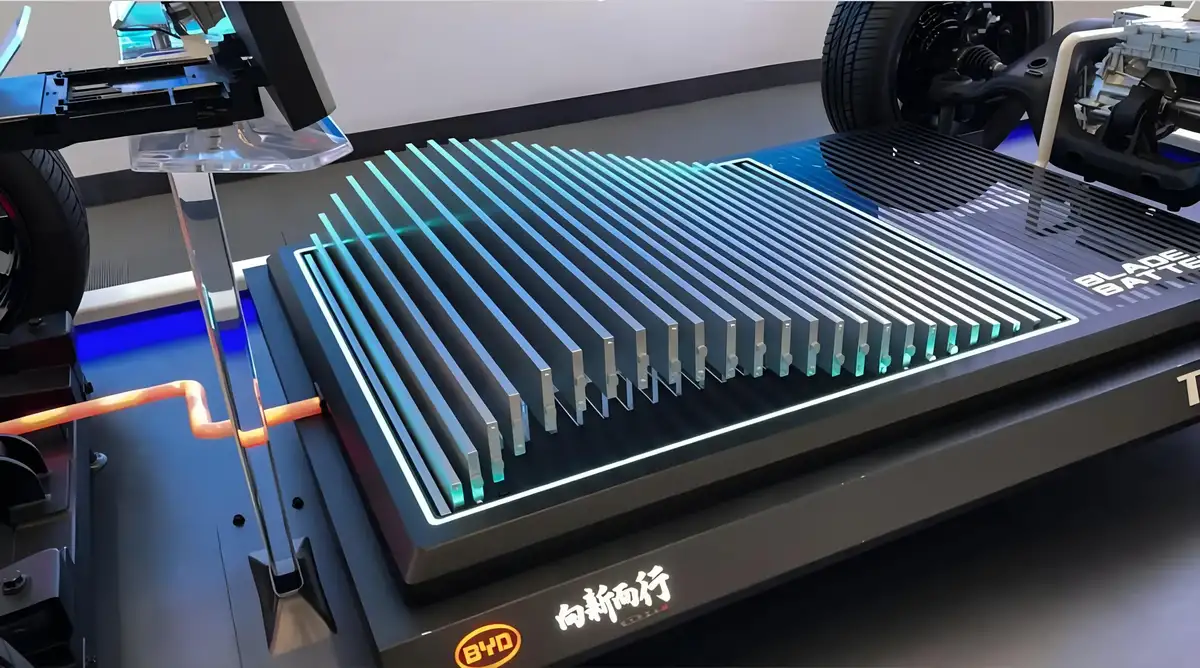

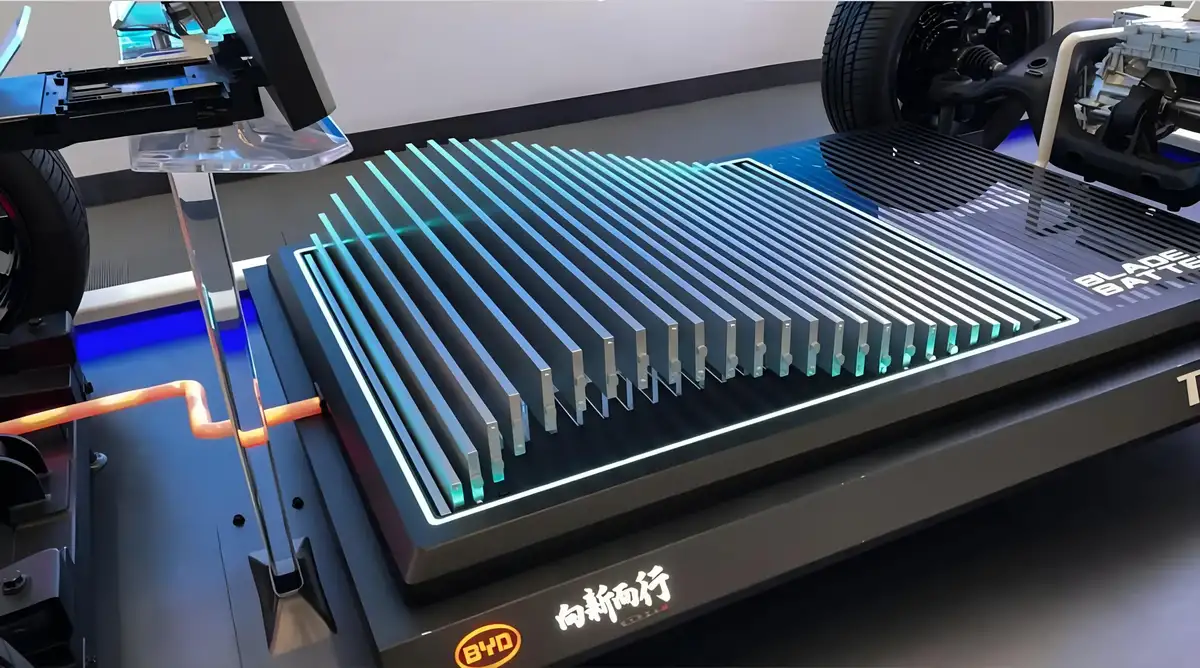

BYD's Blade Battery Technology: A Game Changer

BYD's Blade Battery represents a significant advancement in EV battery technology. Unlike traditional cylindrical or prismatic cells, the Blade Battery is characterized by its unique blade-like form factor. This design offers several key advantages over other battery technologies like LFP (Lithium Iron Phosphate) and NMC (Nickel Manganese Cobalt) batteries.

- Increased range per charge: The high energy density of the Blade Battery allows for a longer driving range on a single charge, a crucial factor for EV adoption.

- Enhanced safety features: The unique design and inherent properties of the Blade Battery significantly improve its safety profile. It's less prone to thermal runaway, a major concern with other battery chemistries.

- Improved vehicle design flexibility: The flat, blade-like shape allows for more efficient packaging within the vehicle chassis, leading to improved interior space and design possibilities.

- Cost-effectiveness: While offering superior performance, BYD's Blade Battery is also reported to be cost-competitive with other leading battery technologies, making EVs more accessible to a wider range of consumers.

Compared to traditional LFP batteries, which often compromise on energy density for safety and longevity, and NMC batteries, which can be more expensive and less stable, BYD's Blade Battery offers a compelling combination of high energy density, improved safety, and cost-effectiveness. This makes it a game-changer in the electric vehicle battery sector.

Vertical Integration: A Key to BYD's Success

BYD's success in EV battery manufacturing is not solely attributed to its innovative Blade Battery technology. A crucial element is its vertically integrated business model. BYD controls a significant portion of its supply chain, from the sourcing of raw materials like lithium and cobalt to the manufacturing of battery cells, battery packs, and even the electric vehicles themselves.

- Reduced reliance on external suppliers: This vertical integration minimizes disruptions caused by supply chain bottlenecks or price fluctuations from external suppliers.

- Enhanced cost control and efficiency: By controlling the entire process, BYD optimizes costs and production efficiency, gaining a competitive advantage in the market.

- Greater control over quality and innovation: Vertical integration allows BYD to maintain stringent quality control throughout the entire manufacturing process and fosters faster innovation cycles.

- Faster response to market demands: This integrated model enables BYD to respond rapidly to changing market demands and emerging technologies.

This strategic approach to EV battery production, driven by its vertical integration, allows BYD to consistently deliver high-quality, cost-effective batteries to the global EV market. The keyword here is "efficiency" – both in terms of production and supply chain management.

Market Dominance and Global Expansion

BYD's strategic investments and operational efficiency have propelled it to a position of market dominance in the EV battery sector. Its global expansion strategy is a key driver of this success.

- Market share data and figures: While precise, publicly available figures fluctuate, BYD consistently ranks among the top EV battery manufacturers globally, holding a significant market share.

- Key geographic markets and growth potential: BYD's market presence spans numerous countries, with significant growth in China, Europe, and other key regions. The company is strategically targeting regions with strong EV adoption policies and high growth potential.

- Partnerships and collaborations: BYD has entered into various partnerships and collaborations with automotive manufacturers and other companies, further strengthening its market position and expanding its reach.

- Strategies for future growth and innovation: BYD continues to invest heavily in research and development, exploring new battery chemistries and technologies to maintain its competitive edge in the evolving EV battery market.

BYD's success demonstrates the power of strategic global expansion, coupled with continuous innovation in EV battery technology and manufacturing.

Sustainability and Environmental Impact

BYD is committed to sustainable battery manufacturing practices, minimizing the environmental impact of its operations.

- Sourcing of raw materials: BYD is increasingly focusing on responsible sourcing of raw materials, prioritizing ethical and sustainable practices throughout its supply chain.

- Recycling initiatives: The company actively invests in recycling programs to recover valuable materials from end-of-life batteries, reducing waste and resource consumption.

- Carbon footprint reduction strategies: BYD employs various strategies to minimize its carbon footprint, from optimizing energy efficiency in its manufacturing facilities to exploring renewable energy sources.

This commitment to sustainability is crucial for maintaining a long-term competitive advantage in the increasingly environmentally conscious EV market. The keywords "green technology" and "sustainable battery" are increasingly important to consumers and investors alike.

Conclusion

This addendum to our case study reveals BYD's strategic approach to EV battery manufacturing, highlighting its innovative Blade Battery technology, vertically integrated business model, and impressive global expansion. BYD's leadership in the EV battery sector underscores its significant impact on the future of electric mobility. By leveraging its technological advancements and efficient production methods, BYD is poised to maintain its leading position in the rapidly growing EV battery market. Further research into BYD’s electric vehicle battery manufacturing strategies will undoubtedly reveal even more insights into the future of this crucial technology. Learn more about the advancements in BYD's electric vehicle battery manufacturing and the company's innovative approach to sustainable energy solutions.

Featured Posts

-

Natural Fiber Composites Market Growth Trends And Opportunities To 2029

May 13, 2025

Natural Fiber Composites Market Growth Trends And Opportunities To 2029

May 13, 2025 -

Live With Kelly And Ryan Addressing Kelly Ripas Absence And Mark Consuelos Role

May 13, 2025

Live With Kelly And Ryan Addressing Kelly Ripas Absence And Mark Consuelos Role

May 13, 2025 -

Record Heat In Southern California La And Orange Counties Face Extreme Temperatures

May 13, 2025

Record Heat In Southern California La And Orange Counties Face Extreme Temperatures

May 13, 2025 -

Yellowstone Creators Next Hit Demi Moore Returns In Season Two

May 13, 2025

Yellowstone Creators Next Hit Demi Moore Returns In Season Two

May 13, 2025 -

The Bce Inc Dividend Reduction What It Means For Your Investments

May 13, 2025

The Bce Inc Dividend Reduction What It Means For Your Investments

May 13, 2025