Case Study Addendum: Examining BYD's Competitive Advantage In EV Batteries

Table of Contents

Main Points: Deconstructing BYD's Competitive Advantage

2.1 Vertical Integration: A Cornerstone of BYD's Success

BYD's vertically integrated business model is a crucial element of its success. Unlike many competitors who rely on external suppliers for various components, BYD controls its entire supply chain, from raw material sourcing to battery cell and pack manufacturing, and even vehicle assembly. This strategic approach offers several significant advantages:

- Cost Control: Internalizing production minimizes reliance on external suppliers, reducing costs associated with procurement, transportation, and potential price fluctuations.

- Supply Chain Security: BYD's integrated model ensures a stable supply of critical materials, mitigating risks associated with supply chain disruptions and geopolitical instability.

- Faster Innovation Cycles: The close integration of R&D, design, and manufacturing enables quicker prototyping, testing, and implementation of new battery technologies and improvements.

Specific examples of BYD's vertical integration include:

- Direct control over crucial raw materials: Securing access to lithium and cobalt, key components in battery production, helps mitigate price volatility and ensures consistent supply.

- In-house R&D: BYD invests heavily in research and development, allowing for continuous innovation in battery chemistries and manufacturing processes.

- Streamlined Production Processes: The integrated model eliminates bottlenecks and inefficiencies often found in fragmented supply chains, resulting in enhanced manufacturing efficiency. This contributes significantly to BYD's cost leadership in the EV battery industry.

2.2 Blade Battery Technology: Innovation and Safety Redefined

BYD's Blade Battery technology represents a significant leap forward in EV battery innovation. Its unique design, utilizing lithium iron phosphate (LFP) chemistry and a blade-like cell form factor, offers several compelling advantages over traditional cylindrical or prismatic cells:

- Higher Energy Density: The Blade Battery achieves a remarkably high energy density, maximizing the range of electric vehicles.

- Improved Safety: Its unique design significantly reduces the risk of thermal runaway, a major safety concern with other battery chemistries. The inherently stable LFP chemistry further contributes to enhanced safety.

- Compact Design: The blade-like form factor allows for more efficient packaging within the vehicle, optimizing space utilization and potentially increasing vehicle range.

Compared to NMC (Nickel Manganese Cobalt) batteries commonly used by competitors, BYD's Blade Battery boasts superior thermal stability and a significantly lower risk of fire, offering a compelling safety advantage. While energy density might be slightly lower compared to some high-nickel NMC chemistries, the safety and cost advantages make it a strong contender.

2.3 Cost Competitiveness and Aggressive Market Penetration

BYD's efficient manufacturing processes and vertical integration directly translate into cost-effective battery production, enabling competitive pricing strategies. This has been instrumental in their market penetration, allowing them to target both the consumer and commercial vehicle sectors:

- Market Share Growth: BYD has rapidly gained market share globally, becoming a leading supplier of EV batteries.

- Pricing Strategy: BYD's ability to control costs allows for competitive pricing, making its EV batteries attractive to a wide range of manufacturers and consumers.

- Global Expansion: BYD is expanding its global footprint, establishing manufacturing facilities and partnerships to meet the growing demand for its batteries. This global expansion is a crucial component of its market penetration strategy.

- Strategic Partnerships: Collaborations with other automakers and companies further enhance BYD's reach and market penetration.

This combination of cost leadership and strategic market penetration positions BYD for continued growth in the rapidly expanding EV market.

2.4 Sustainable Practices and Environmental Responsibility

BYD's commitment to sustainability is another key differentiator. The company actively pursues environmentally responsible practices throughout its supply chain:

- Sustainable Manufacturing: BYD focuses on reducing its carbon footprint through energy-efficient manufacturing processes and renewable energy utilization.

- Green Technology: The company's efforts extend to developing and implementing green technologies, including battery recycling programs.

- Responsible Sourcing: BYD actively works to ensure responsible sourcing of raw materials, minimizing environmental impact and promoting ethical practices.

- Battery Recycling Initiatives: BYD is investing in advanced battery recycling technologies, aiming to recover valuable materials and reduce waste.

These initiatives contribute to a circular economy model, minimizing the environmental impact of EV battery production and consumption.

Conclusion: Understanding BYD's Competitive Edge in the EV Battery Market

This case study addendum highlights BYD's significant competitive advantage in the burgeoning EV battery market. Its vertically integrated business model, innovative Blade Battery technology, cost competitiveness, and commitment to sustainability combine to create a potent formula for success. The implications of BYD's achievements are far-reaching, influencing the direction of technological development and industry standards within the broader EV sector. To further explore the intricacies of BYD's competitive advantage in EV batteries, delve into our comprehensive case study and stay ahead of the curve in the rapidly evolving landscape of EV battery technology.

Featured Posts

-

Moskva Ploschadka Dlya Rossiysko Myanmanskogo Delovogo Foruma

May 13, 2025

Moskva Ploschadka Dlya Rossiysko Myanmanskogo Delovogo Foruma

May 13, 2025 -

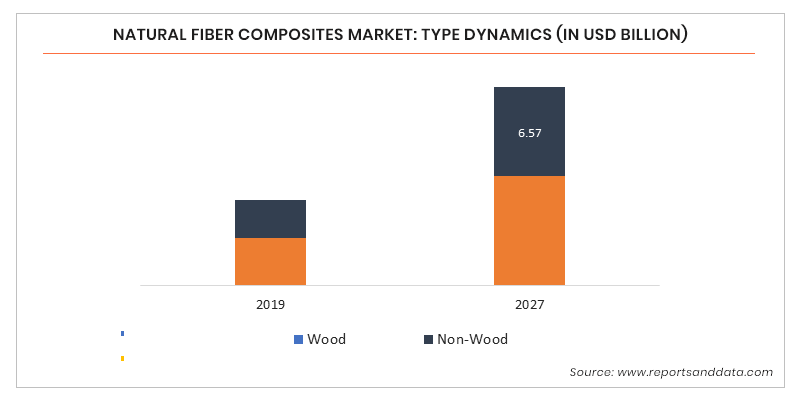

Natural Fiber Composites Market Global Forecast To 2029

May 13, 2025

Natural Fiber Composites Market Global Forecast To 2029

May 13, 2025 -

Grigoriy Kostyuk Biografiya Syna Tatyany Kadyshevoy

May 13, 2025

Grigoriy Kostyuk Biografiya Syna Tatyany Kadyshevoy

May 13, 2025 -

Blow Your Mind Top 10 Unbelievable Things You Need To See

May 13, 2025

Blow Your Mind Top 10 Unbelievable Things You Need To See

May 13, 2025 -

Hannover 96 Drohkulisse Und Derby Stimmung In Der 2 Liga

May 13, 2025

Hannover 96 Drohkulisse Und Derby Stimmung In Der 2 Liga

May 13, 2025