Cost-Cutting Measures Rise As U.S. Companies Face Tariff Uncertainty

Table of Contents

Supply Chain Restructuring

The fluctuating nature of tariffs necessitates a fundamental reassessment of supply chain strategies. Companies are actively seeking ways to mitigate the impact of these tariffs on their bottom line, leading to significant restructuring efforts.

Nearshoring and Reshoring

The trend of near-shoring and re-shoring—moving manufacturing closer to home—is gaining significant traction. This strategy aims to avoid or minimize tariff costs associated with imported goods.

- Increased transportation costs: While closer proximity reduces transit time, transportation costs within the US might be higher than those from overseas.

- Reduced lead times: Bringing manufacturing closer results in significantly faster delivery times and improved responsiveness to market demands.

- Improved quality control: Closer proximity allows for more direct oversight of the manufacturing process, potentially leading to enhanced quality control.

- Potential higher labor costs: Labor costs in the US are generally higher than in many other countries, which needs to be factored into the cost-benefit analysis.

- Challenges in finding skilled labor: Securing a skilled workforce for reshored operations can be a significant hurdle in certain sectors.

These factors necessitate a careful evaluation of near-shoring and re-shoring as part of a broader supply chain optimization strategy aimed at tariff mitigation.

Diversifying Suppliers

Reducing reliance on single suppliers located in tariff-affected regions is another key strategy. Diversifying suppliers across multiple countries helps spread risk and mitigate the impact of potential tariff increases on any single source.

- Reduced risk of supply disruptions: Having multiple suppliers reduces vulnerability to disruptions caused by tariffs, political instability, or natural disasters.

- Increased negotiation power: Working with multiple suppliers provides greater leverage in negotiations, potentially leading to better pricing and terms.

- Potential for higher overall costs: Managing multiple suppliers introduces complexities that can increase administrative and logistical costs.

- Increased complexity in supply chain management: Tracking and coordinating materials and production across multiple global supply chains requires sophisticated supply chain management systems.

Supplier diversification is a crucial element of risk mitigation within the context of global supply chains.

Automation and Technological Investments

To reduce reliance on labor-intensive processes and increase efficiency, many companies are investing heavily in automation and technology.

Robotics and Automation

The adoption of robots and automated systems is accelerating across various industries. This shift aims to reduce labor costs while simultaneously boosting productivity.

- Reduced labor costs: Automation can significantly decrease labor expenses, especially in repetitive or physically demanding tasks.

- Increased productivity: Automated systems often operate more consistently and at a faster pace than human workers, leading to increased output.

- Higher upfront investment costs: Implementing robotics and automation requires significant upfront capital investment in equipment and infrastructure.

- Potential job displacement: Automation can lead to job losses in certain sectors, creating social and economic challenges.

- Need for skilled technicians: Maintaining and operating sophisticated automated systems requires a skilled workforce of technicians and engineers.

These technological investments represent a long-term strategy for labor cost reduction.

Software and Efficiency Improvements

Beyond robotics, investments in software and process improvements are vital for streamlining operations and enhancing efficiency.

- Improved efficiency: Software solutions can optimize workflows, reduce redundancies, and improve overall operational efficiency.

- Reduced waste: Streamlined processes lead to minimized waste of materials, time, and resources.

- Better data analysis: Data analytics tools provide insights into operational inefficiencies and areas for improvement.

- Need for employee training: Implementing new software and processes requires adequate training for employees to ensure successful adoption.

- Initial investment costs: The initial investment in software and training can be significant but pays off in the long run through improved efficiency.

Process optimization through software solutions and data analytics leads to significant efficiency gains and cost savings.

Reducing Workforce and Labor Costs

In some cases, cost-cutting measures necessitate difficult decisions regarding the workforce. These measures can have significant ethical and social implications.

Layoffs and Hiring Freezes

Layoffs and hiring freezes are often employed as drastic measures to reduce labor costs quickly.

- Reduced labor costs: Layoffs directly reduce salary and benefit expenses. Hiring freezes prevent the addition of new employees to the payroll.

- Potential loss of skilled employees: Layoffs can result in the loss of valuable employees with specialized skills and experience.

- Negative impact on morale: Layoffs and hiring freezes can negatively affect employee morale and productivity.

- Potential legal ramifications: Companies must comply with relevant employment laws and regulations when implementing layoffs.

Workforce reduction is a last resort for cost control, requiring careful consideration of its impact.

Wage Reductions and Benefit Cuts

Wage reductions and benefit cuts are another sensitive area of cost-cutting, often met with employee resistance.

- Reduced labor costs: Decreasing wages and benefits directly lowers labor expenses.

- Potential employee dissatisfaction: Wage and benefit cuts can lead to decreased employee morale, productivity, and retention.

- Impact on employee retention: Reduced compensation can drive high-performing employees to seek employment elsewhere.

- Potential legal challenges: Reductions in wages and benefits must comply with all applicable labor laws.

Cost containment through wage cuts and benefit reductions should be carefully evaluated given the risks to employee morale.

Conclusion

U.S. companies are facing significant challenges due to tariff uncertainty, leading them to adopt a range of cost-cutting measures. These strategies, from reshoring and automation to workforce reductions, reflect a proactive approach to mitigating financial risks. However, many of these measures have long-term consequences that need careful consideration. Understanding and proactively implementing effective cost-cutting measures is crucial for U.S. businesses navigating this turbulent economic climate. Learn more about how to strategize your approach to cost-cutting strategies and build resilience against future tariff uncertainty.

Featured Posts

-

How Middle Managers Drive Company Performance And Employee Engagement

Apr 29, 2025

How Middle Managers Drive Company Performance And Employee Engagement

Apr 29, 2025 -

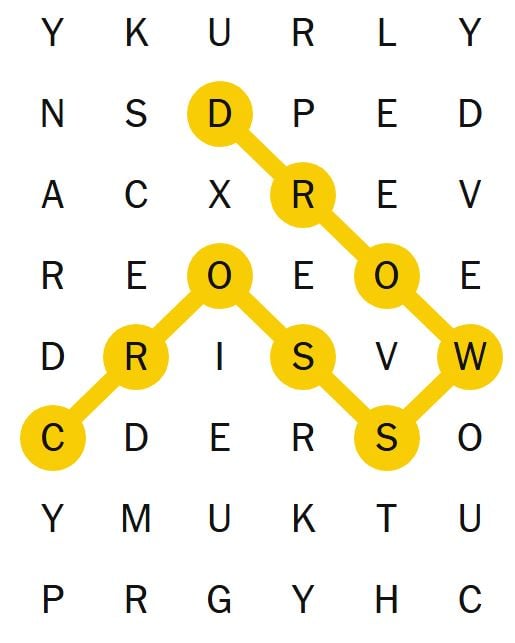

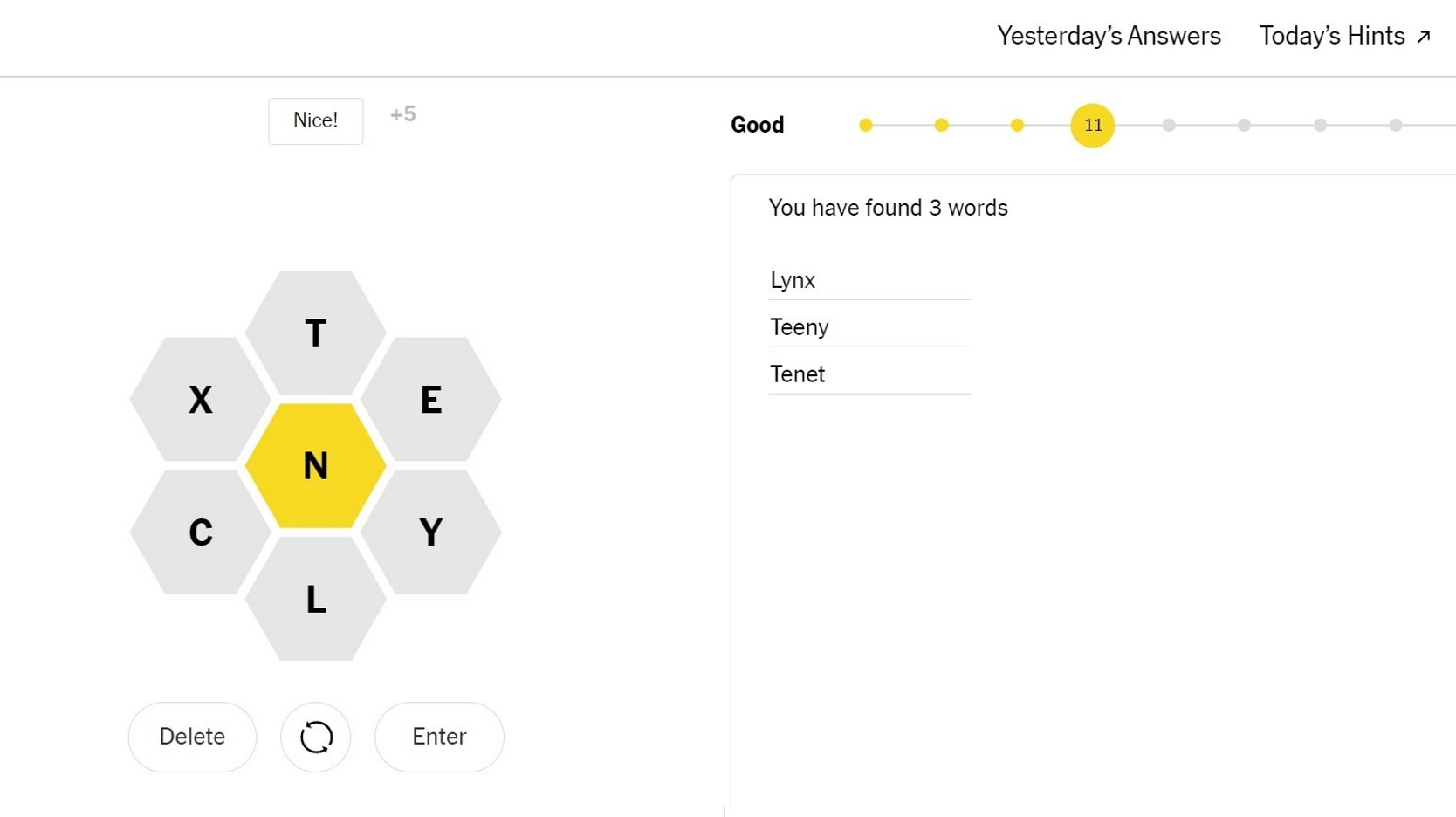

Nyt Spelling Bee March 13 2025 Complete Solutions And Pangram

Apr 29, 2025

Nyt Spelling Bee March 13 2025 Complete Solutions And Pangram

Apr 29, 2025 -

Bof A On Stock Market Valuations Why Investors Shouldnt Panic

Apr 29, 2025

Bof A On Stock Market Valuations Why Investors Shouldnt Panic

Apr 29, 2025 -

Revolutionizing Voice Assistant Development Open Ais Latest Tools

Apr 29, 2025

Revolutionizing Voice Assistant Development Open Ais Latest Tools

Apr 29, 2025 -

Trumps Transgender Sports Ban Us Attorney General Targets Minnesota

Apr 29, 2025

Trumps Transgender Sports Ban Us Attorney General Targets Minnesota

Apr 29, 2025

Latest Posts

-

Nyt Spelling Bee February 10 2025 Complete Guide To Clues And Answers

Apr 29, 2025

Nyt Spelling Bee February 10 2025 Complete Guide To Clues And Answers

Apr 29, 2025 -

Solve The Nyt Spelling Bee March 13 2025 Answers And Pangram

Apr 29, 2025

Solve The Nyt Spelling Bee March 13 2025 Answers And Pangram

Apr 29, 2025 -

Revealed How Xs Debt Financing Restructured The Company

Apr 29, 2025

Revealed How Xs Debt Financing Restructured The Company

Apr 29, 2025 -

The Impact Of Xs Debt Sale A Financial Performance Analysis

Apr 29, 2025

The Impact Of Xs Debt Sale A Financial Performance Analysis

Apr 29, 2025 -

Nyt Spelling Bee March 13 2025 Complete Solutions And Pangram

Apr 29, 2025

Nyt Spelling Bee March 13 2025 Complete Solutions And Pangram

Apr 29, 2025