Decarbonizing Steel Production: Eramet's EraLow Manganese Alloy

Table of Contents

Understanding the Challenges of Traditional Steelmaking

The Carbon Footprint of Steel Production

Traditional steelmaking, primarily using blast furnaces, relies heavily on coal for energy and as a reducing agent. This process generates substantial carbon emissions. The carbon intensity of steel production is a significant concern, impacting the environment and contributing to global warming.

- Coal use: Blast furnaces consume vast quantities of coal, directly contributing to greenhouse gas emissions.

- CO2 emissions per ton of steel: Traditional methods can generate several tons of CO2 for every ton of steel produced. Estimates vary, but the figure is consistently high, highlighting the urgent need for change.

- Environmental regulations: Increasingly stringent environmental regulations globally are pushing the steel industry to reduce its carbon footprint, demanding innovation and sustainable practices.

The Need for Sustainable Alternatives

The pressure on the steel industry to reduce its environmental impact is mounting. Governments worldwide are implementing stricter emission standards and carbon pricing mechanisms, while consumers are increasingly demanding environmentally friendly products. The shift towards sustainable steel production is no longer optional; it's a necessity.

- EU Emissions Trading System (ETS): The EU ETS, and similar schemes globally, directly impact the cost of carbon emissions for steel producers, incentivizing the adoption of lower-carbon technologies.

- Corporate sustainability goals: Many steel companies are setting ambitious sustainability goals, aiming to reduce their carbon emissions significantly in the coming decades. Meeting these targets requires technological innovation and the adoption of solutions like eraLow.

- Consumer preference for sustainable materials: Consumers are becoming more aware of the environmental impact of their purchases. Demand for sustainably produced steel is growing, creating a market incentive for green steel solutions.

Eramet's eraLow Manganese Alloy: A Game Changer

The Technology Behind eraLow

Eramet's eraLow manganese alloy represents a breakthrough in sustainable steelmaking. Its unique composition and properties allow for significantly reduced energy consumption and lower greenhouse gas emissions during the steel production process. The precise details of the alloy's formulation are proprietary, but its effectiveness in reducing the carbon footprint is well-documented.

- Reduced energy consumption: eraLow contributes to lower energy needs in the steelmaking process, further minimizing the carbon footprint.

- Lower emissions of greenhouse gases: By reducing the reliance on high-carbon processes, eraLow helps to dramatically decrease greenhouse gas emissions associated with steel production.

- Improved process efficiency: The alloy's properties optimize the steelmaking process, leading to improved efficiency and reduced waste.

Benefits of Using eraLow

Incorporating eraLow manganese alloy into steel production offers a range of significant advantages beyond its environmental benefits:

- Cost savings: While initial investment may be required, the reduced energy consumption and improved efficiency associated with eraLow can lead to substantial cost savings in the long run.

- Improved material properties: eraLow can enhance the mechanical properties of the resulting steel, making it suitable for a wider range of applications.

- Enhanced sustainability profile: The use of eraLow allows steel producers to significantly improve their sustainability credentials, meeting evolving environmental regulations and consumer expectations.

- Compliance with environmental standards: Steel produced using eraLow is better positioned to comply with increasingly stringent environmental regulations globally.

Applications of eraLow

The versatility of steel produced using eraLow makes it suitable for a diverse range of applications:

- Automotive: The automotive industry, a major steel consumer, is under increasing pressure to reduce its carbon footprint. eraLow offers a pathway to more sustainable vehicle production.

- Construction: In the construction sector, the use of sustainable materials is becoming increasingly important. Steel produced with eraLow can contribute to greener buildings and infrastructure.

- Infrastructure: Large-scale infrastructure projects can benefit from the use of low-carbon steel, reducing their overall environmental impact.

- Appliances: Household appliances produced with sustainable steel appeal to environmentally conscious consumers.

The Future of Sustainable Steel Production with eraLow

Scalability and Market Adoption

The widespread adoption of eraLow has the potential to revolutionize the steel industry. Eramet is actively working to scale up production capacity and foster partnerships with steel producers globally to facilitate its integration into existing processes.

- Investment in production capacity: Eramet is investing in expanding its production capabilities to meet the growing demand for eraLow.

- Partnerships with steel producers: Eramet is collaborating with steel manufacturers worldwide to support the implementation of eraLow in their operations.

- Industry collaborations: Eramet is actively engaged in industry collaborations to promote the adoption of sustainable steelmaking practices.

Further Research and Development

Continuous research and development efforts are underway to further improve the performance and sustainability of eraLow:

- Exploring new alloy compositions: Research is ongoing to explore variations in the alloy's composition to further optimize its properties and reduce its environmental impact.

- Optimizing the steelmaking process: Eramet is collaborating with steel producers to optimize the steelmaking process to maximize the benefits of eraLow.

- Life cycle assessment studies: Comprehensive life cycle assessments are conducted to fully evaluate the environmental benefits of eraLow throughout its entire lifecycle.

Conclusion

Eramet's eraLow manganese alloy offers a significant breakthrough in the quest for decarbonizing steel production. Its benefits—reduced emissions, cost-effectiveness, and improved material properties—position it as a key player in the transition to a more sustainable steel industry. By reducing the carbon footprint of steel production, eraLow contributes directly to a greener future.

Call to Action: Learn more about how Eramet's eraLow manganese alloy can help your company achieve its sustainability goals and contribute to a greener future for steel production. Contact us today to discuss integrating eraLow into your steelmaking process and explore the possibilities of sustainable, low-carbon steel.

Featured Posts

-

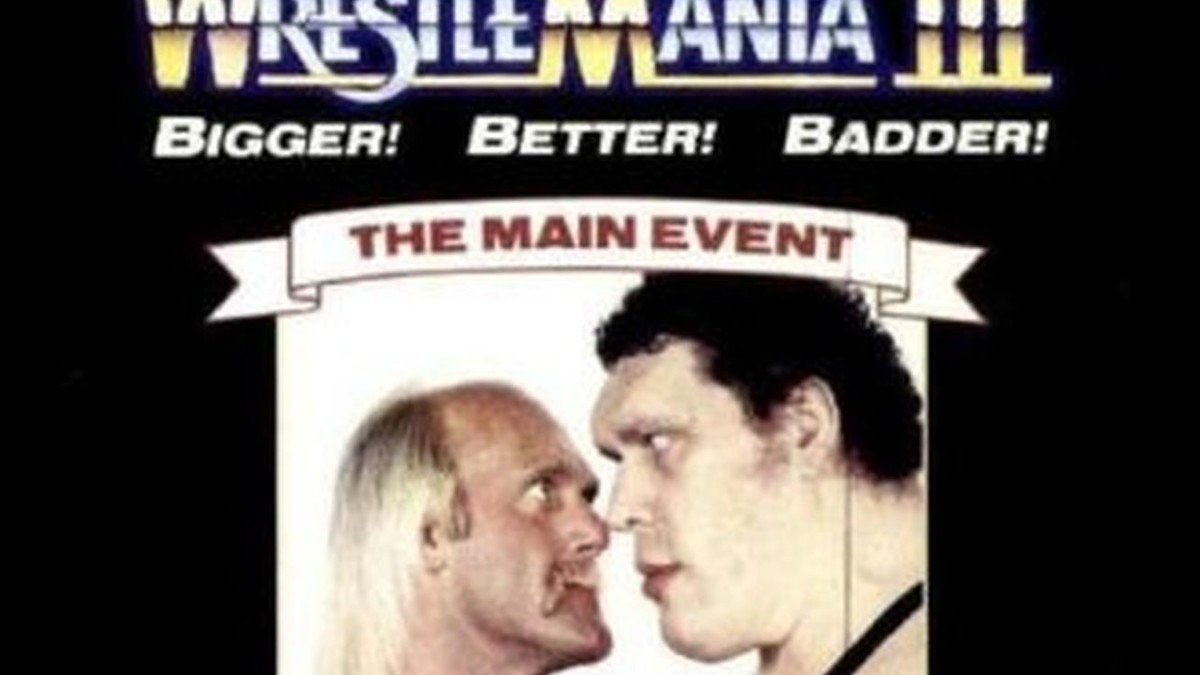

Wwe Vault Presents Wrestle Mania Iii Livestream

May 14, 2025

Wwe Vault Presents Wrestle Mania Iii Livestream

May 14, 2025 -

Wynonna And Ashley Judds Docuseries Uncovering Family Truths

May 14, 2025

Wynonna And Ashley Judds Docuseries Uncovering Family Truths

May 14, 2025 -

Opera V Sauni Na Yevrobachenni 2025 Reaktsiya Publiki Ta Ekspertiv

May 14, 2025

Opera V Sauni Na Yevrobachenni 2025 Reaktsiya Publiki Ta Ekspertiv

May 14, 2025 -

Dokovicev Uspon Preuzimanje Federerove Dominacije

May 14, 2025

Dokovicev Uspon Preuzimanje Federerove Dominacije

May 14, 2025 -

Update On A Potential Tommy Boy Sequel With David Spade

May 14, 2025

Update On A Potential Tommy Boy Sequel With David Spade

May 14, 2025

Latest Posts

-

Kanye West And Bianca Censori A Spanish Restaurant Reunion

May 14, 2025

Kanye West And Bianca Censori A Spanish Restaurant Reunion

May 14, 2025 -

Newcastle United Transfer News Blow As Club Misses Out On Top Target

May 14, 2025

Newcastle United Transfer News Blow As Club Misses Out On Top Target

May 14, 2025 -

Bianca Censori Resurfaces With Kanye West In Spain Relationship Status Update

May 14, 2025

Bianca Censori Resurfaces With Kanye West In Spain Relationship Status Update

May 14, 2025 -

Newcastle News Premier League Defender Deal Expected To Fail

May 14, 2025

Newcastle News Premier League Defender Deal Expected To Fail

May 14, 2025 -

Liverpools Aggressive E60m Transfer Strategy Securing The Deal

May 14, 2025

Liverpools Aggressive E60m Transfer Strategy Securing The Deal

May 14, 2025