Electric Motor Independence: Breaking Free From Chinese Dependence

Table of Contents

The Current State of Electric Motor Dependence on China

China's dominance in the global electric motor market is undeniable. This concentration poses substantial economic and geopolitical risks. The vulnerability of various sectors, including the automotive industry and renewable energy sectors, to disruptions in the Chinese supply chain is a growing concern. This dependence translates into significant trade imbalances and increases our susceptibility to geopolitical pressures.

- China's Market Share: China currently holds a substantial majority of the global market share for electric motor production, particularly in certain critical segments like those used in electric vehicles (EVs) and wind turbines. Precise figures vary depending on the source and specific motor type, but estimates suggest a market share exceeding 50% in several key areas.

- Economic Risks: Over-reliance on a single source for such a vital component introduces significant economic risks. Price fluctuations, supply chain disruptions due to natural disasters or political instability, and potential trade wars can all severely impact industries reliant on these motors.

- Geopolitical Risks: The concentration of electric motor production in China creates geopolitical vulnerabilities. Any political tension or conflict could easily disrupt the supply chain, causing significant economic damage to importing nations.

- Import Statistics: The volume of electric motor imports from China is staggering, highlighting the extent of this dependence. Analyzing specific import data from relevant sources would reveal the sheer magnitude of this reliance and its impact on national economies.

Strategic Initiatives for Achieving Electric Motor Independence

Achieving electric motor independence requires a multi-pronged approach involving government intervention, private sector investment, and technological innovation. A concerted effort across these areas is vital.

- Government Incentives: Governments must implement robust policies and incentives to stimulate domestic electric motor production. This includes tax breaks, grants, subsidies, and streamlined regulatory processes specifically tailored to attract investment in this sector. Furthermore, tariffs or import restrictions on Chinese motors could make domestic production more competitive.

- Reshoring and Foreign Investment: Attracting foreign investment and reshoring electric motor manufacturing are critical steps. Incentives should be designed to entice companies to establish or expand manufacturing facilities within the country, creating jobs and boosting domestic production.

- Technological Innovation: Investing in research and development is crucial for improving domestic production capabilities. This involves funding innovation in electric motor design, materials science, and manufacturing processes to create more efficient and cost-competitive motors.

- Workforce Development: The growth of the domestic electric motor industry requires a skilled workforce. Investment in education and training programs to equip workers with the necessary skills is essential for long-term success. This includes apprenticeships, vocational training, and university programs focused on relevant engineering and manufacturing disciplines.

- Supply Chain Diversification: Reducing reliance on single sources is crucial. This means actively seeking alternative suppliers from diverse geographical locations, ensuring that disruptions in one region don't cripple the entire supply chain. This diversification can encompass both raw materials and component sourcing.

Technological Advancements and Innovation in Electric Motor Manufacturing

Significant technological advancements are key to fostering domestic electric motor production and competitiveness.

- Advanced Motor Designs: Improvements in motor design, including the development of more efficient and powerful motors using advanced materials, are crucial. This includes research into high-torque density motors, permanent magnet motors, and switched reluctance motors, each offering unique advantages.

- Automation and AI: Automation and artificial intelligence (AI) can significantly streamline manufacturing processes, improving efficiency, reducing costs, and enhancing quality control. Robotics, automated assembly lines, and AI-powered predictive maintenance are all integral components of a modern, efficient manufacturing facility.

- Sustainable Materials: The use of sustainable and ethically sourced materials reduces the environmental impact of electric motor production. This includes exploring alternatives to rare earth magnets and employing recycled materials whenever possible.

- Next-Generation Motors: Investing in the development of next-generation electric motors with superior performance characteristics—higher efficiency, greater power density, and extended lifespan—is vital for maintaining a competitive edge in the global market. This includes exploring new motor topologies and advanced control strategies.

The Economic and National Security Implications of Electric Motor Independence

Achieving electric motor independence has profound economic and national security implications.

- Job Creation and Economic Growth: Domestic electric motor manufacturing stimulates job creation across various sectors, from manufacturing and engineering to research and development, ultimately boosting economic growth.

- National Security and Supply Chain Resilience: Electric motor independence is paramount for national security and supply chain resilience. Reducing reliance on a single foreign supplier strengthens a nation's ability to withstand geopolitical shocks and maintain critical infrastructure functionality.

- Energy Independence: The production of electric motors is intrinsically linked to energy production and consumption. Domestic production enhances energy independence by supporting the growth of renewable energy sources and reducing reliance on foreign energy supplies.

- Reduced Trade Deficits: Shifting electric motor production from overseas to domestic facilities reduces reliance on imports and helps to balance trade deficits, strengthening the national economy.

Conclusion

Reliance on China for electric motor production presents significant economic and national security risks. Mitigating these risks requires a strategic shift towards electric motor independence. This involves a combination of government incentives, private sector investment in domestic manufacturing, technological innovation, and supply chain diversification. Investing in electric motor independence is not merely a business strategy; it's a crucial step towards ensuring economic stability and national security. Let's accelerate the transition towards domestic electric motor production and break free from Chinese dependence. Support policies that promote electric motor independence and invest in the future of American manufacturing.

Featured Posts

-

Harvard President Denounces Attempts To Revoke Universitys Tax Exempt Status

May 05, 2025

Harvard President Denounces Attempts To Revoke Universitys Tax Exempt Status

May 05, 2025 -

Nhl Highlights Avalanche Defeat Panthers Despite Late Comeback

May 05, 2025

Nhl Highlights Avalanche Defeat Panthers Despite Late Comeback

May 05, 2025 -

Kentucky Derby 2025 Live Stream Where To Watch And How Much It Costs

May 05, 2025

Kentucky Derby 2025 Live Stream Where To Watch And How Much It Costs

May 05, 2025 -

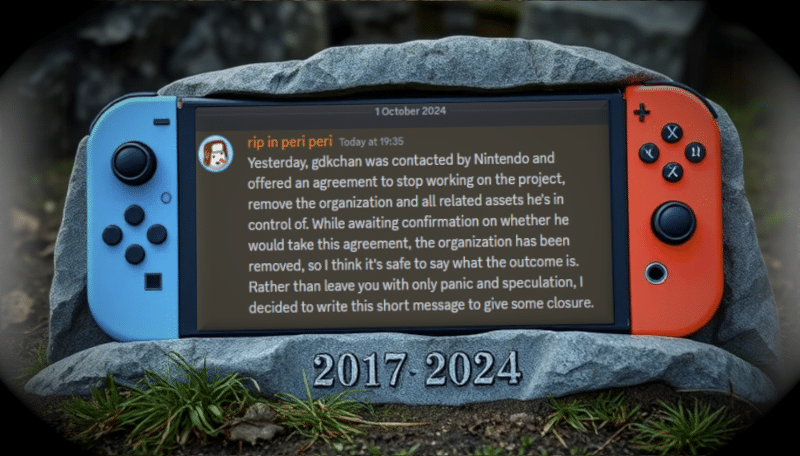

End Of Ryujinx Emulator Project Halted After Nintendo Intervention

May 05, 2025

End Of Ryujinx Emulator Project Halted After Nintendo Intervention

May 05, 2025 -

Section 230 And Banned Chemicals Impact On E Bay Listings

May 05, 2025

Section 230 And Banned Chemicals Impact On E Bay Listings

May 05, 2025

Latest Posts

-

16 Year Olds Torture Leads To Stepfathers Murder Indictment

May 05, 2025

16 Year Olds Torture Leads To Stepfathers Murder Indictment

May 05, 2025 -

Jail Sentences For Cult Members In Disturbing Child Death Case

May 05, 2025

Jail Sentences For Cult Members In Disturbing Child Death Case

May 05, 2025 -

Murder And Torture Charges Filed Against Stepfather In Teens Death

May 05, 2025

Murder And Torture Charges Filed Against Stepfather In Teens Death

May 05, 2025 -

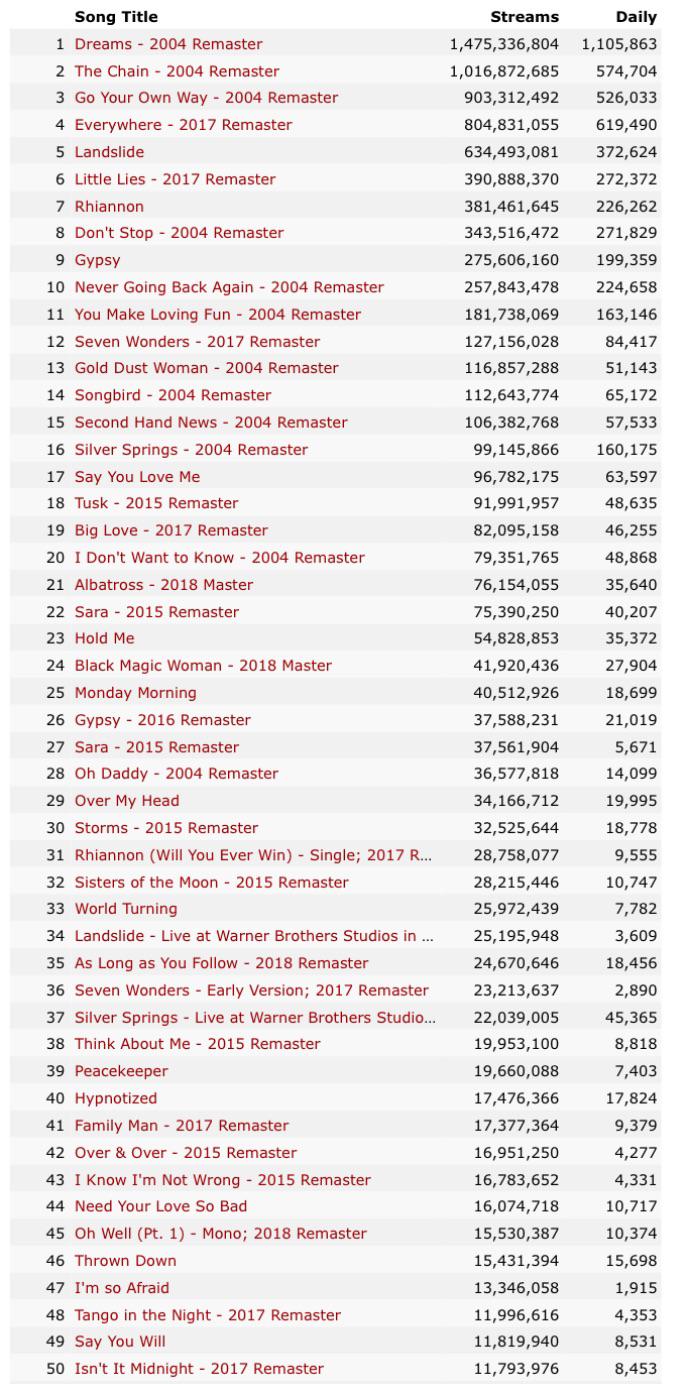

The Most Popular Fleetwood Mac Songs Of All Time

May 05, 2025

The Most Popular Fleetwood Mac Songs Of All Time

May 05, 2025 -

Cult Group Members Jailed For Childs Disturbing Death

May 05, 2025

Cult Group Members Jailed For Childs Disturbing Death

May 05, 2025