Electric Motors: Reducing Global Reliance On China

Table of Contents

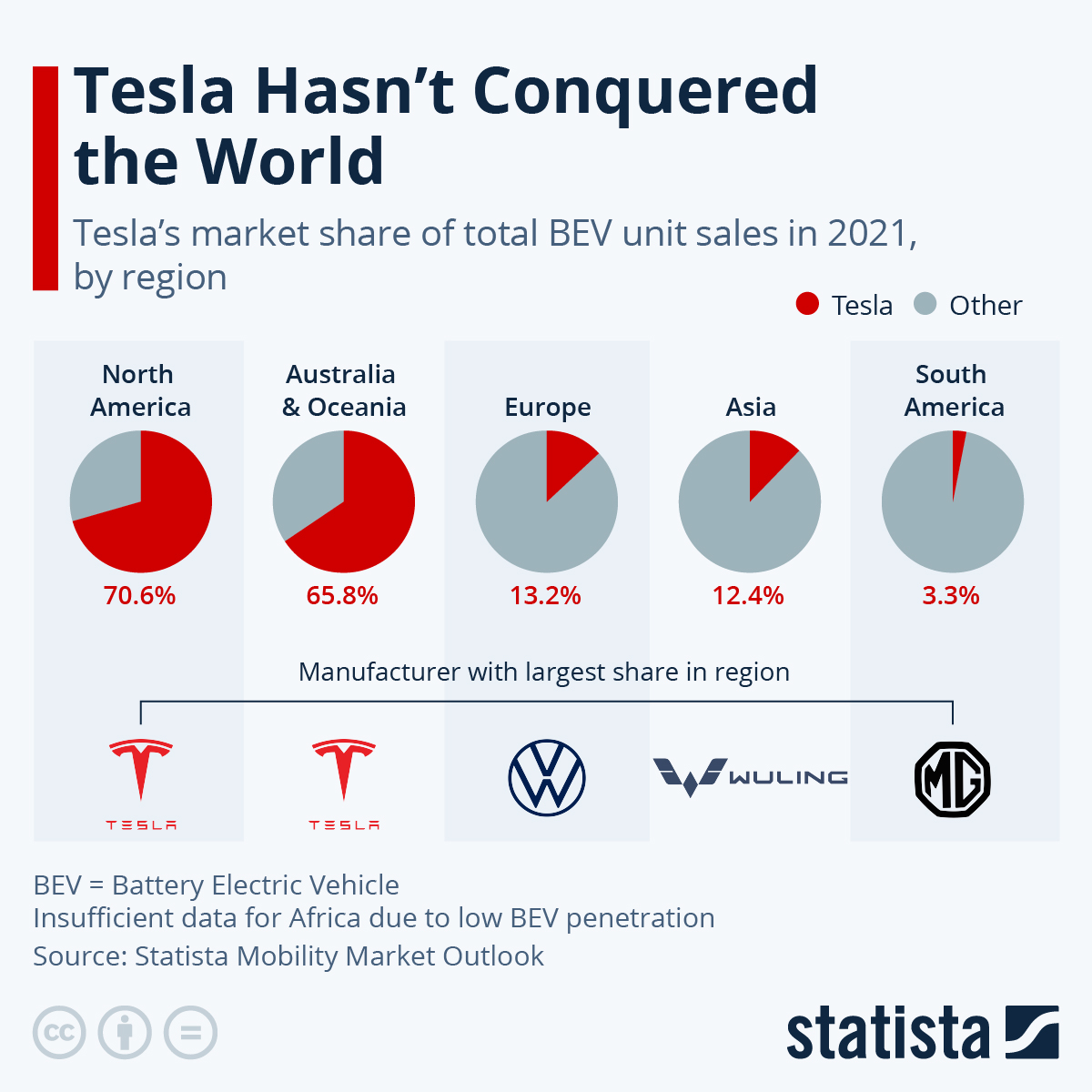

The Current State of Electric Motor Manufacturing: China's Grip

China's dominance in the electric motor industry is undeniable. They currently control a significant portion of the global electric motor market share, estimated to be over [Insert Percentage, cite source]. This dominance stems from several factors:

- Cost-effective manufacturing: Chinese manufacturers benefit from lower labor costs and established supply chains, making their electric motors significantly cheaper than those produced elsewhere.

- Supply chain integration: China boasts a robust and vertically integrated supply chain for electric motor components, allowing for efficient production and economies of scale.

- Government subsidies and support: Significant government investment and favorable policies have further fueled China's growth in the electric motor supply chain.

However, this over-reliance on Chinese electric motor manufacturers presents considerable risks:

- Geopolitical instability: Political tensions and trade disputes can easily disrupt the supply of electric motors, impacting industries worldwide.

- Supply chain disruptions: Natural disasters, pandemics, or other unforeseen events can severely impact production and delivery, leading to shortages and delays.

- Trade wars: Escalating trade tensions could lead to tariffs and other trade barriers, increasing the cost of electric motors and hindering technological advancements.

Strategies for Diversifying Electric Motor Production

To mitigate these risks, diversifying electric motor production is paramount. Several key strategies can be implemented:

Investing in Domestic Manufacturing

Governments worldwide are increasingly recognizing the need to boost domestic electric motor manufacturing. Incentives such as tax breaks, grants, and subsidies are being offered to attract investment and stimulate growth. Successful examples include [mention specific examples of government initiatives in different countries]. The focus on reshoring electric motors and near-shoring – bringing production closer to home markets – is gaining significant traction.

- Targeted investment in infrastructure: Building modern manufacturing facilities and developing skilled workforces are essential for successful domestic production.

- Streamlined regulatory processes: Reducing bureaucratic hurdles and simplifying permits can significantly accelerate the establishment of new manufacturing plants.

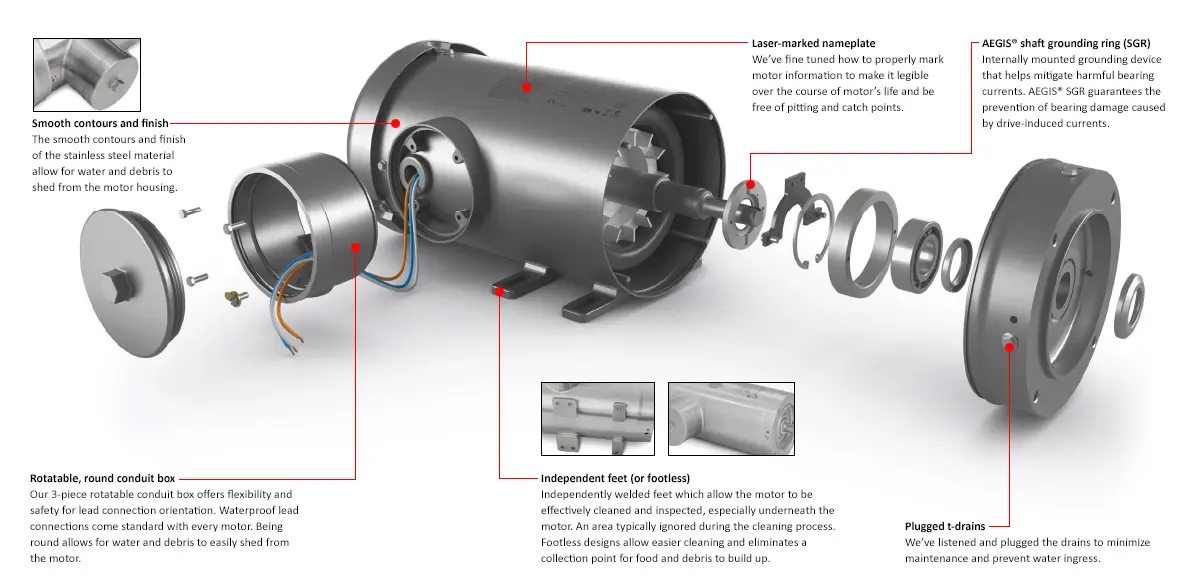

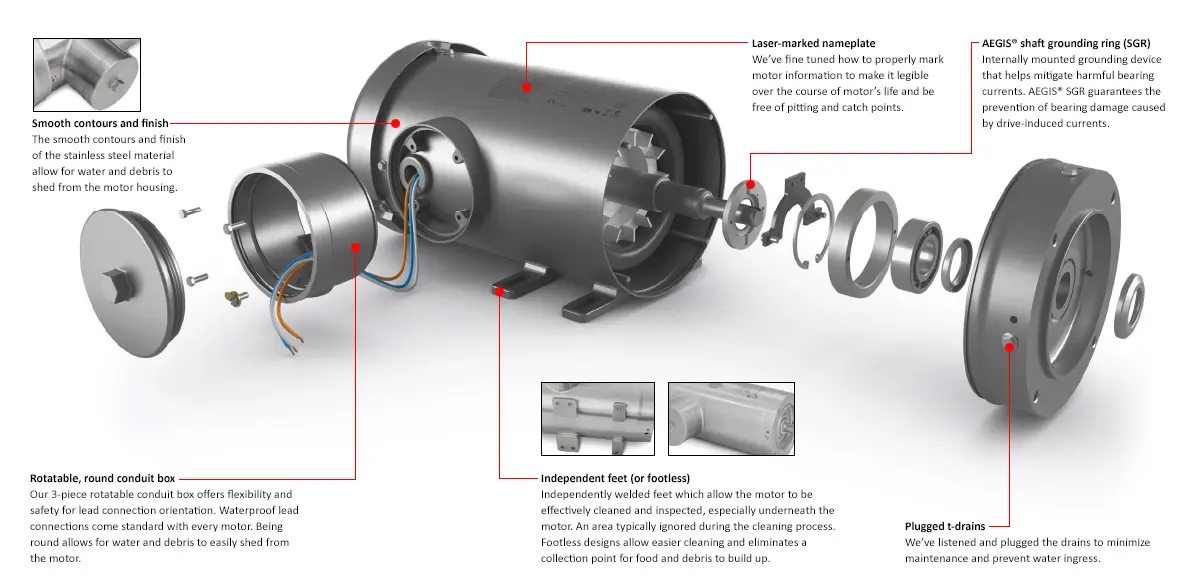

Fostering Technological Innovation

Investment in R&D in electric motors is critical for developing advanced and competitive technologies. This includes:

- Developing next-generation electric motors: Focusing on improving efficiency, reducing costs, and enhancing performance is crucial for staying ahead in the competitive global market.

- Protecting intellectual property: Strong IP protection safeguards innovations and encourages further investment in electric motor technology and electric motor innovation.

- Promoting collaboration: Encouraging partnerships between universities, research institutions, and private companies fosters innovation and accelerates technological advancements.

Strengthening International Partnerships

Building international electric motor partnerships is key to diversifying the supply chain and sharing resources. This includes:

- Strategic alliances: Forming strategic alliances between companies in different countries allows for collaborative manufacturing, risk sharing, and access to diverse expertise.

- Joint ventures: Joint ventures can combine resources and knowledge, accelerating the development and production of electric motors.

- Technology transfer agreements: Facilitating the transfer of technology and expertise between countries promotes widespread adoption of advanced electric motor technologies. This promotes global electric motor collaboration and supply chain diversification.

The Role of Sustainable Practices in Electric Motor Production

The transition to electric motors must be coupled with a commitment to sustainable electric motor manufacturing. This includes:

- Minimizing environmental impact: Employing environmentally friendly manufacturing processes and reducing carbon emissions throughout the production cycle.

- Utilizing recycled materials: Incorporating recycled materials in the production process reduces reliance on virgin resources and minimizes waste.

- Adopting renewable energy sources: Powering manufacturing facilities with renewable energy sources reduces reliance on fossil fuels and minimizes the carbon footprint.

- Adherence to standards: Meeting certifications like ISO 14001 (environmental management) ensures commitment to sustainable manufacturing practices. The production of green electric motors and eco-friendly electric motor production are becoming increasingly important.

Conclusion: A Future Less Reliant on Single Sources for Electric Motors

Diversifying electric motor production is no longer a luxury but a necessity. By investing in domestic electric motor manufacturing, fostering technological innovation, strengthening international partnerships, and embracing sustainable practices, we can create a more resilient and secure global supply chain. Reducing our reliance on a single source for such a crucial component is essential for economic stability and national security. Investing in the future of electric motors means actively reducing our reliance on single-source manufacturing. Let's explore sustainable and diversified solutions today!

Featured Posts

-

The China Market Obstacles And Opportunities For Luxury Car Manufacturers

May 04, 2025

The China Market Obstacles And Opportunities For Luxury Car Manufacturers

May 04, 2025 -

Increased Training Intensity Ajagba Vs Bakole

May 04, 2025

Increased Training Intensity Ajagba Vs Bakole

May 04, 2025 -

The Nuggets Westbrook Situation An Official Response

May 04, 2025

The Nuggets Westbrook Situation An Official Response

May 04, 2025 -

Lizzo Returns With A Fiery New Track

May 04, 2025

Lizzo Returns With A Fiery New Track

May 04, 2025 -

Exploring The Reported Feud Between Blake Lively And Anna Kendrick A Timeline

May 04, 2025

Exploring The Reported Feud Between Blake Lively And Anna Kendrick A Timeline

May 04, 2025