Eramet's EraLow: Low-CO2 Manganese Alloy For Sustainable Steel

Table of Contents

The Environmental Impact of Traditional Steelmaking

High Carbon Emissions from Manganese Production

Manganese alloys are crucial components in steelmaking, enhancing its strength and durability. However, the production of traditional manganese alloys carries a significant environmental burden. The process is energy-intensive, relying heavily on fossil fuels, and generates substantial greenhouse gas emissions.

- Sources of CO2 Emissions:

- High energy consumption in smelting and refining processes.

- Emissions from the combustion of fossil fuels used for energy.

- Process emissions from chemical reactions during manganese production.

- Environmental Consequences: These high carbon emissions contribute directly to climate change, air pollution, and the depletion of natural resources. The impact on the environment is substantial, making the search for sustainable alternatives a critical priority.

The Urgency for Sustainable Alternatives

The pressure on the steel industry to decarbonize is intensifying. Stringent environmental regulations and evolving consumer preferences are driving the demand for low-carbon steel products.

- Environmental Regulations and Initiatives: The EU Green Deal, for example, sets ambitious targets for emissions reduction across various industries, including steel. Carbon pricing mechanisms are also being implemented globally, adding financial incentives for companies to reduce their carbon footprint.

- Market Demand for Low-Carbon Steel: Consumers are increasingly demanding sustainable products, giving companies that prioritize environmental responsibility a significant competitive advantage. The market for low-carbon steel is expanding rapidly, creating lucrative opportunities for innovative solutions like eraLow.

Eramet's eraLow: A Game Changer in Sustainable Steel Production

The Low-CO2 Production Process

Eramet's eraLow represents a significant advancement in sustainable manganese alloy production. Its manufacturing process incorporates innovative technologies designed to minimize CO2 emissions.

- Technological Advancements: Eramet employs a combination of renewable energy sources, process optimization techniques, and potentially carbon capture technologies (depending on the specific production site) to drastically reduce its environmental impact.

- CO2 Emission Reduction: Compared to traditional methods, eraLow boasts a substantially lower CO2 footprint. Eramet has publicly committed to specific percentage reductions which can be found on their website. [Insert specific percentage reduction data from Eramet’s official sources here].

Superior Performance and Properties

Eramet’s commitment to sustainability doesn't compromise on performance. eraLow delivers excellent mechanical properties, matching or exceeding the capabilities of traditional manganese alloys.

- Key Performance Characteristics: eraLow exhibits high tensile strength, excellent ductility, and superior weldability, ensuring its suitability for a wide range of steel applications.

- Performance Comparison: Independent testing demonstrates that eraLow performs comparably to, or even better than, traditional manganese alloys in key performance metrics, proving that sustainability and performance can coexist.

Applications and Market Opportunities

eraLow's versatility makes it suitable for various steel production processes and industries.

- Steel Product Applications: eraLow finds applications in automotive steel, construction steel, and energy infrastructure projects, contributing to the creation of more sustainable products across diverse sectors.

- Market Potential: The market for low-carbon manganese alloys is projected to experience significant growth in the coming years, presenting a substantial opportunity for steel producers seeking to meet the increasing demand for sustainable materials.

The Benefits of Choosing eraLow for Sustainable Steel

Environmental Responsibility

By choosing eraLow, steel manufacturers actively contribute to a greener future.

- Reduced Carbon Footprint: Using eraLow directly translates to lower CO2 emissions, helping companies achieve their sustainability goals and contribute to global climate change mitigation efforts.

- Circular Economy Contribution: The sustainable production methods employed in creating eraLow support the principles of a circular economy, minimizing waste and promoting resource efficiency.

Economic Advantages

The adoption of eraLow offers significant economic benefits.

- Cost Savings: Improved process efficiency and reduced energy consumption can lead to cost reductions in the long run.

- Access to New Markets: The increasing demand for low-carbon steel opens new market opportunities for steel producers using eraLow.

- Enhanced Brand Reputation: Adopting sustainable practices, like using eraLow, enhances a company's brand image and attracts environmentally conscious customers.

Meeting Regulatory Requirements

Eramet's eraLow helps steel producers comply with evolving environmental regulations.

- Compliance with Standards: The low-carbon footprint of eraLow aids in meeting increasingly stringent environmental standards and industry certifications. [Insert references to relevant standards and certifications here.]

Conclusion

Eramet's eraLow represents a significant leap forward in sustainable steel production. Its low-CO2 emissions, superior performance characteristics, and contribution to a greener future make it an attractive option for steel manufacturers committed to environmental responsibility. By adopting eraLow, steel producers can reduce their carbon footprint, improve their economic competitiveness, and meet stringent environmental regulations. Discover the future of sustainable steel with eraLow. Contact us today to learn how eraLow can help you achieve your sustainability goals and reduce your carbon footprint with Eramet's low-CO2 manganese alloy. Visit the Eramet website for more information.

Featured Posts

-

Eurovision Song Contest 2025 Full Schedule Of Events

May 14, 2025

Eurovision Song Contest 2025 Full Schedule Of Events

May 14, 2025 -

Top Rated Unique Restaurant In New York Unforgettable Dining

May 14, 2025

Top Rated Unique Restaurant In New York Unforgettable Dining

May 14, 2025 -

Premier League Star A Target For Arsenal Ornstein

May 14, 2025

Premier League Star A Target For Arsenal Ornstein

May 14, 2025 -

Is Dean Huijsen The Next Premier League Star Transfer Rumour Mill Churns

May 14, 2025

Is Dean Huijsen The Next Premier League Star Transfer Rumour Mill Churns

May 14, 2025 -

The Woman Behind Tommy Tiernan Stepping Out Of The Spotlight And Into The Vatican

May 14, 2025

The Woman Behind Tommy Tiernan Stepping Out Of The Spotlight And Into The Vatican

May 14, 2025

Latest Posts

-

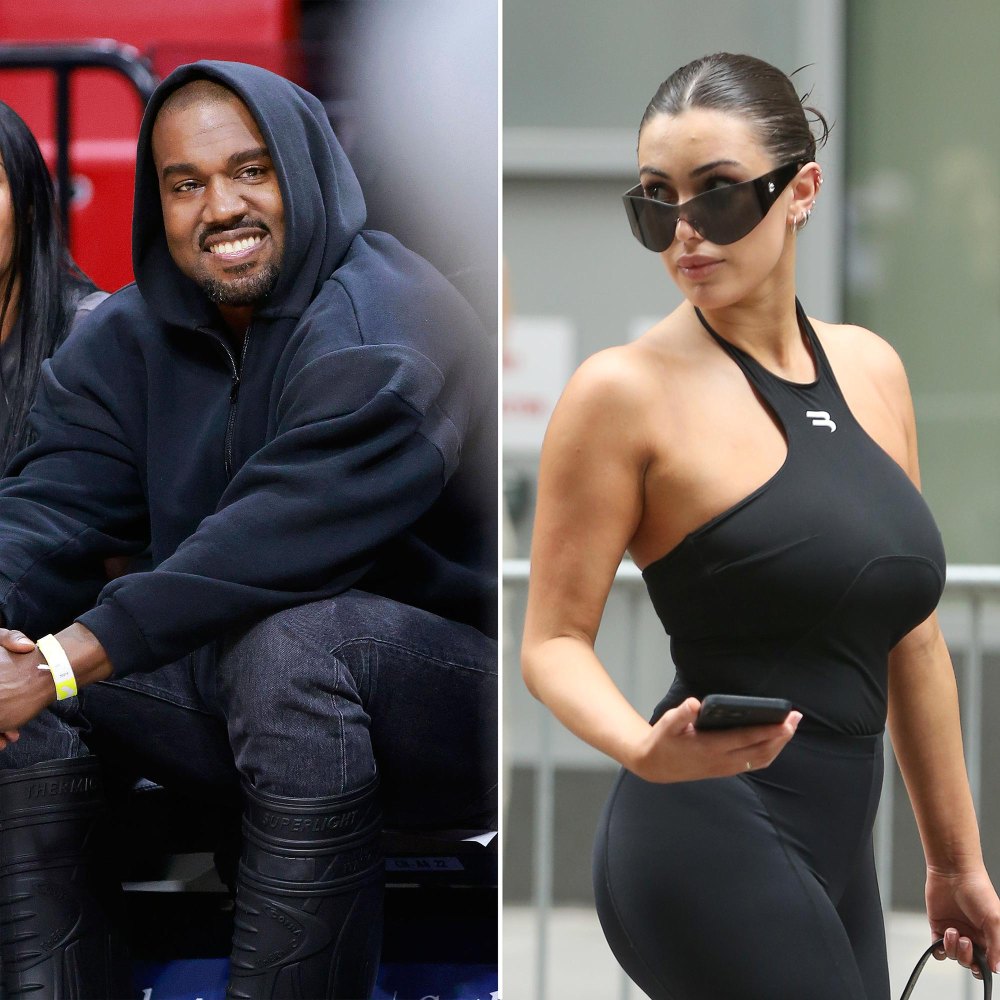

Bianca Censori Italy Lingerie Rollerblading Appearance Sparks Buzz

May 14, 2025

Bianca Censori Italy Lingerie Rollerblading Appearance Sparks Buzz

May 14, 2025 -

Bianca Censoris Latest Stunt Lingerie Rollerblading In Italy Without Kanye

May 14, 2025

Bianca Censoris Latest Stunt Lingerie Rollerblading In Italy Without Kanye

May 14, 2025 -

Kanye Wests Wife Bianca Censori Spotted Rollerblading In Italy In Lingerie

May 14, 2025

Kanye Wests Wife Bianca Censori Spotted Rollerblading In Italy In Lingerie

May 14, 2025 -

Kanye And Bianca Reconciling After A Post Grammys Separation

May 14, 2025

Kanye And Bianca Reconciling After A Post Grammys Separation

May 14, 2025 -

Are Kanye West And Bianca Censori Back Together Post Grammys

May 14, 2025

Are Kanye West And Bianca Censori Back Together Post Grammys

May 14, 2025