Eramet's EraLow: Low-CO2 Manganese Alloy For Sustainable Steelmaking

Table of Contents

The Environmental Impact of eraLow

The environmental benefits of eraLow are substantial. Compared to traditional manganese alloys, eraLow boasts a significantly lower carbon footprint, contributing directly to reduced emissions and a smaller impact on the planet. This low-CO2 manganese alloy represents a crucial advancement in the quest for green steel. The reduction in greenhouse gas (GHG) emissions is a key differentiator. While precise figures depend on the specific production methods compared, Eramet's internal assessments show a considerable percentage reduction – a figure that is continuously being improved through ongoing research and development efforts.

- Substantially lower greenhouse gas (GHG) emissions during production, leading to a smaller carbon footprint for the entire steel production process.

- Reduced reliance on high-carbon energy sources, shifting towards more sustainable alternatives and promoting energy efficiency.

- Contribution to achieving net-zero targets within the steel industry, assisting steelmakers in meeting ambitious sustainability goals.

- Improved lifecycle assessment (LCA) compared to traditional alternatives, showcasing eraLow's overall environmental superiority throughout its entire life cycle. Eramet is committed to transparent LCA reporting.

The Production Process of eraLow

Eramet's commitment to sustainable production is reflected in the manufacturing process of eraLow. Innovative technologies and responsible sourcing practices are at the core of its creation. The production process emphasizes energy efficiency and minimizes environmental impact at every stage.

- Use of renewable energy sources in the manufacturing process wherever possible, reducing reliance on fossil fuels.

- Optimized energy consumption for reduced emissions, minimizing waste and maximizing efficiency.

- Implementation of circular economy principles in material sourcing and waste management, striving for a closed-loop system to reduce waste and resource consumption.

- Transparency and traceability throughout the supply chain, ensuring responsible sourcing and ethical production practices. Customers can readily access information regarding the entire eraLow supply chain.

Benefits for Steelmakers Adopting eraLow

Integrating eraLow into steel production offers numerous benefits for steelmakers, extending beyond mere environmental responsibility. Adopting this low-CO2 manganese alloy presents both economic and environmental advantages, bolstering a company's sustainability initiatives and enhancing its competitiveness in a rapidly evolving market.

- Reduced carbon tax liabilities and compliance costs, ensuring compliance with increasingly stringent environmental regulations.

- Enhanced brand reputation and improved consumer perception, appealing to environmentally conscious consumers and investors.

- Meeting growing demand for sustainable steel products, securing a strong position in a market increasingly focused on green steel.

- Access to innovative and high-quality manganese alloy, ensuring superior performance and quality in steel production.

- Potential for cost savings through improved energy efficiency and reduced waste.

eraLow and the Future of Sustainable Steel

eraLow plays a pivotal role in shaping the future of sustainable steelmaking. It represents a significant step towards decarbonization strategies within the steel industry and reflects the growing importance of the circular economy. Eramet continues to invest in research and development, exploring further innovations in low-carbon manganese alloys and other green steel technologies. The future of steel is undoubtedly linked to innovations like eraLow, enabling the industry to meet its ambitious sustainability goals.

Conclusion

Eramet's eraLow offers a compelling solution for sustainable steelmaking. Its significantly reduced CO2 emissions during production, coupled with its sustainable manufacturing process, provides steelmakers with a clear path towards environmental responsibility and economic advantage. By adopting eraLow, steel producers can reduce their carbon footprint, enhance their brand image, and meet the growing demand for green steel.

Eramet's eraLow is a pivotal solution for achieving sustainable steelmaking. Contact us today to learn more about integrating this low-CO2 manganese alloy into your production processes and contributing to a greener future for the steel industry. Explore the possibilities of eraLow and join the movement towards sustainable steel production.

Featured Posts

-

Mission Impossible Dead Reckoning 40 Below Filming Challenges In Svalbard

May 14, 2025

Mission Impossible Dead Reckoning 40 Below Filming Challenges In Svalbard

May 14, 2025 -

Urgent Recall Dangerous Coffee Creamer Found In Michigan Stores

May 14, 2025

Urgent Recall Dangerous Coffee Creamer Found In Michigan Stores

May 14, 2025 -

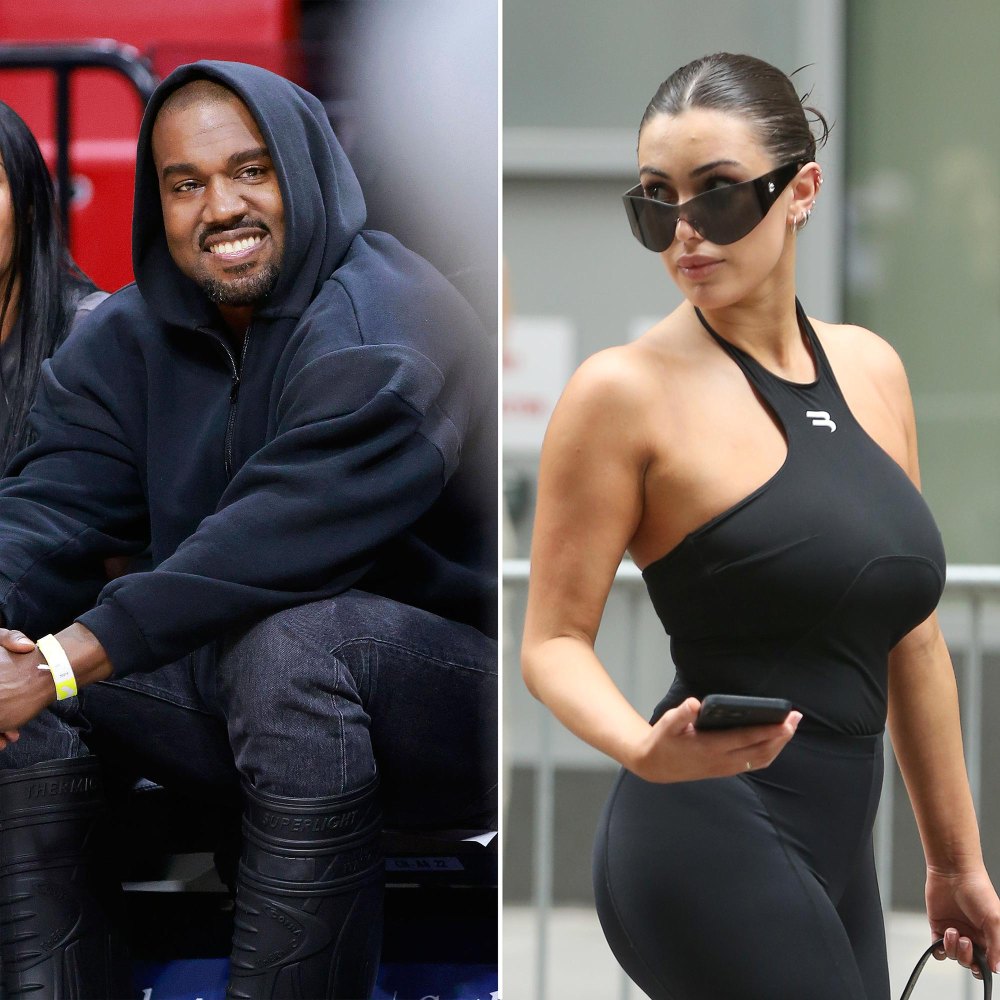

Kanye Wests Post Bianca Censori Life New Relationship Or Just Friends

May 14, 2025

Kanye Wests Post Bianca Censori Life New Relationship Or Just Friends

May 14, 2025 -

Santo Confirms Awoniyi Fit For Newcastle Clash Epl Update

May 14, 2025

Santo Confirms Awoniyi Fit For Newcastle Clash Epl Update

May 14, 2025 -

Eurojackpotin Jaettipotti Nousee 54 Miljoonaa Euroa Jaossa

May 14, 2025

Eurojackpotin Jaettipotti Nousee 54 Miljoonaa Euroa Jaossa

May 14, 2025

Latest Posts

-

Are Kanye West And Bianca Censori Back Together Post Grammys

May 14, 2025

Are Kanye West And Bianca Censori Back Together Post Grammys

May 14, 2025 -

Liverpools Summer Signing Teammates Confirmation

May 14, 2025

Liverpools Summer Signing Teammates Confirmation

May 14, 2025 -

Confirmed Liverpool Targets Summer Move

May 14, 2025

Confirmed Liverpool Targets Summer Move

May 14, 2025 -

Kanye Wests Post Bianca Censori Life New Relationship Or Just Friends

May 14, 2025

Kanye Wests Post Bianca Censori Life New Relationship Or Just Friends

May 14, 2025 -

Kanye Wests New Companion Resemblance To Bianca Censori Fuels Rumors

May 14, 2025

Kanye Wests New Companion Resemblance To Bianca Censori Fuels Rumors

May 14, 2025