F-35 Program's Inventory Deficiencies: Pentagon Audit Exposes Significant Challenges

Table of Contents

The Pentagon Audit: Methodology and Key Findings

The Pentagon audit, conducted over a [Insert timeframe, e.g., six-month period], meticulously examined the inventory management practices and supply chain processes related to the F-35 program. Its scope encompassed all major F-35 components across the entire fleet, including those deployed globally. The methodology involved a comprehensive review of existing inventory records, physical inspections of parts and aircraft, and interviews with key personnel involved in F-35 maintenance and logistics.

Audit Scope and Methodology:

The audit's scope was extensive, covering various aspects of F-35 inventory management. This included:

- Detailed examination of spare parts inventories: The audit scrutinized warehouses and depots across multiple locations, checking for discrepancies between reported quantities and actual physical counts.

- Analysis of supply chain data: The audit reviewed data from various sources, including suppliers, manufacturers, and logistics providers, to identify bottlenecks and inefficiencies.

- Assessment of maintenance and repair procedures: The audit reviewed procedures to identify areas where improvements could be made to reduce downtime and optimize part usage.

Impact on F-35 Operational Readiness:

The audit uncovered significant inventory discrepancies, directly impacting the operational readiness of the F-35 fleet. These deficiencies translate into:

- A significant percentage of F-35s grounded due to parts shortages – estimates range from [Insert percentage range, e.g., 10% to 25%], depending on the variant and location.

- Reduced training exercise capacity and limited mission capabilities: The lack of readily available parts restricts training exercises and reduces the number of aircraft available for deployment.

- Potential security implications: The reduced operational capacity due to parts shortages presents a vulnerability, potentially affecting national security. The audit highlighted instances where critical parts were unavailable, delaying crucial maintenance and compromising operational readiness.

Root Causes of F-35 Inventory Management Problems

The F-35 program's inventory issues stem from a confluence of factors, encompassing supply chain vulnerabilities and logistical challenges.

Supply Chain Issues:

The F-35's complex global supply chain presents inherent challenges:

- Supplier delays and production bottlenecks: Numerous suppliers contribute parts to the F-35, and delays by even a single supplier can cause cascading effects across the entire supply chain.

- Difficulties in tracking parts and components: Tracking parts across the complex global network proves difficult, leading to inaccurate inventory records and delays in identifying missing components.

- Lack of effective inventory management systems: The audit revealed deficiencies in the software and systems used to manage and track F-35 parts, contributing to the inventory discrepancies.

Logistics and Maintenance Challenges:

Logistical and maintenance hurdles further exacerbate the inventory problems:

- Inefficient maintenance procedures: Inefficient repair and maintenance procedures can lead to the unnecessary consumption of spare parts.

- Lack of sufficient spare parts stockpiles: The audit revealed that current stockpiles are inadequate to meet the demands of the F-35 fleet, particularly for high-demand components.

- Problems with parts identification and tracking: Issues with proper part identification and tracking contribute to inventory inaccuracy and delays in ordering replacements.

Potential Solutions and Recommendations to Address F-35 Inventory Deficiencies

Addressing the F-35 inventory deficiencies requires a multi-faceted approach, focusing on improving supply chain management and enhancing logistics and maintenance processes.

Improving Supply Chain Management:

Several measures can significantly improve the F-35 supply chain:

- Implementing advanced inventory management systems: Investing in robust, integrated inventory management systems can greatly improve part tracking and forecasting.

- Strengthening relationships with suppliers: Fostering stronger relationships with key suppliers can improve communication, reduce delays, and enhance the overall supply chain’s resilience.

- Diversifying suppliers: Reducing dependence on single-source suppliers can mitigate the risk of delays caused by any single supplier's issues.

Enhancing Logistics and Maintenance Processes:

Optimizing logistics and maintenance can also make a significant impact:

- Improving parts tracking and identification systems: Adopting advanced technologies such as RFID or blockchain can improve the accuracy and efficiency of part tracking.

- Optimizing maintenance schedules: Refining maintenance schedules and implementing predictive maintenance strategies can reduce the demand for spare parts and minimize aircraft downtime.

- Increasing spare parts stockpiles: Strategic increases in spare parts stockpiles are crucial to ensure sufficient supply to meet operational demands.

Conclusion: Addressing the Critical F-35 Inventory Shortages

The Pentagon audit's findings on F-35 program inventory deficiencies paint a concerning picture. The identified shortfalls in parts, coupled with supply chain vulnerabilities and logistical challenges, significantly impact the operational readiness and effectiveness of the F-35 fleet. Addressing these F-35 inventory issues is not merely a logistical concern; it is a critical matter of national security. Understanding the depth of these F-35 program inventory deficiencies is crucial. Stay informed on developments and demand solutions to ensure the long-term readiness and effectiveness of this critical asset. Addressing the F-35's inventory problems requires immediate and decisive action by all stakeholders. Failure to do so jeopardizes the future readiness and combat effectiveness of this vital component of our national defense.

Featured Posts

-

No 10 Texas Tech Edges Out Kansas 78 73

May 01, 2025

No 10 Texas Tech Edges Out Kansas 78 73

May 01, 2025 -

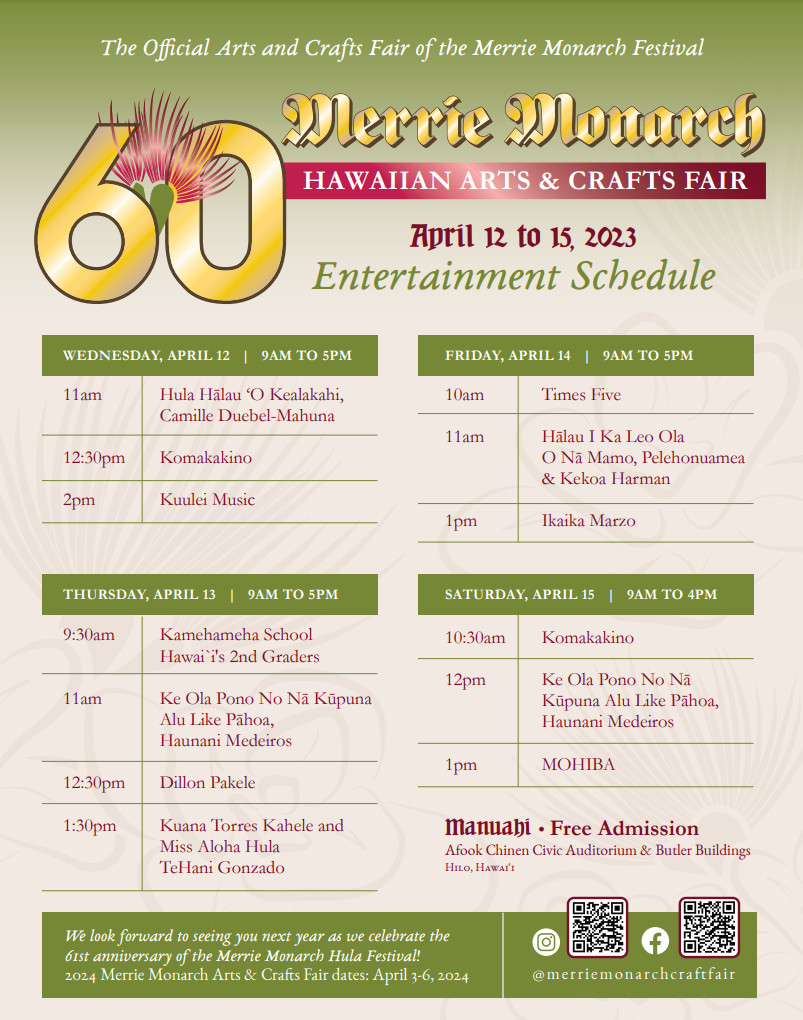

The Merrie Monarch Festival Exploring Pacific Island Dance And Music Through The Hoike

May 01, 2025

The Merrie Monarch Festival Exploring Pacific Island Dance And Music Through The Hoike

May 01, 2025 -

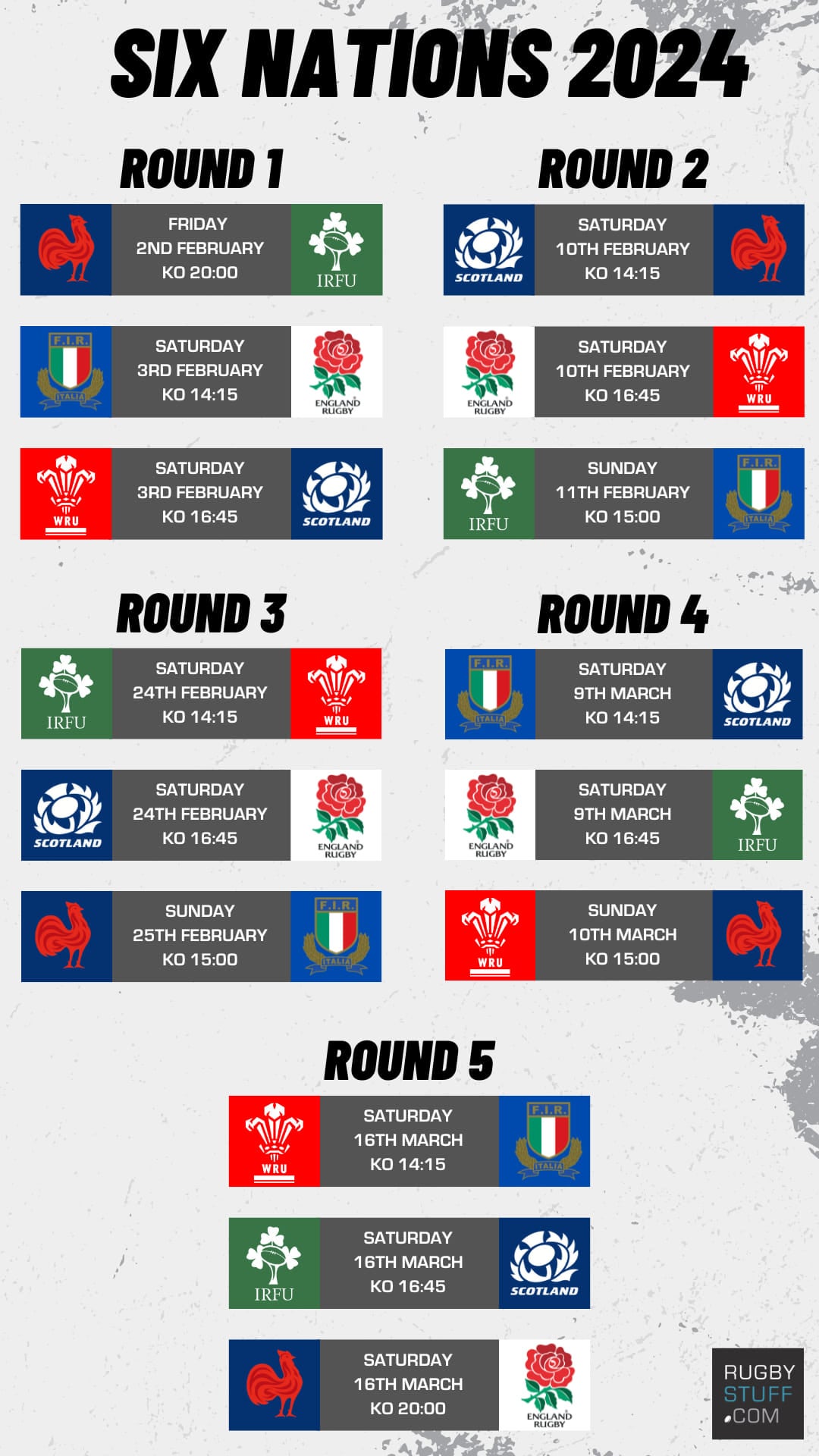

Six Nations 2025 Frances Rugby Renaissance

May 01, 2025

Six Nations 2025 Frances Rugby Renaissance

May 01, 2025 -

Juridische Strijd Kampen Eist Stroomnetaansluiting Van Enexis

May 01, 2025

Juridische Strijd Kampen Eist Stroomnetaansluiting Van Enexis

May 01, 2025 -

Christopher Stevens Review Michael Sheens Million Pound Giveaway

May 01, 2025

Christopher Stevens Review Michael Sheens Million Pound Giveaway

May 01, 2025

Latest Posts

-

Cruise Line Complaints Permanent Bans What You Need To Know

May 01, 2025

Cruise Line Complaints Permanent Bans What You Need To Know

May 01, 2025 -

Can Cruise Lines Ban You For Complaining The Shocking Truth

May 01, 2025

Can Cruise Lines Ban You For Complaining The Shocking Truth

May 01, 2025 -

Understanding Carnival Corporation All Its Owned Cruise Lines

May 01, 2025

Understanding Carnival Corporation All Its Owned Cruise Lines

May 01, 2025 -

Alaska 2026 Disney Cruise Line Deploys Two Ships

May 01, 2025

Alaska 2026 Disney Cruise Line Deploys Two Ships

May 01, 2025 -

Carnivals Cruise Lines A Detailed Look At The Corporations Brands

May 01, 2025

Carnivals Cruise Lines A Detailed Look At The Corporations Brands

May 01, 2025