Improved Delivery Times For Saab's Defense Orders

Table of Contents

Streamlined Supply Chain Management

Saab's success in reducing delivery times for defense orders is significantly attributed to a streamlined and optimized supply chain. Effective supply chain management is crucial in the defense industry, where timely delivery of critical components is paramount. Saab has implemented several key strategies to achieve this:

-

Implementing advanced inventory management systems for better stock control and reduced delays: Saab leverages sophisticated inventory management software that provides real-time visibility into stock levels, minimizing the risk of stockouts and delays caused by missing parts. This system utilizes predictive analytics to forecast demand and optimize inventory levels, ensuring that necessary components are available when needed for weapon systems and other military equipment.

-

Strengthening relationships with key suppliers to ensure timely delivery of components: Building strong, collaborative relationships with suppliers is key to a successful supply chain. Saab works closely with its key suppliers, fostering open communication and establishing clear expectations regarding delivery timelines and quality control for crucial components used in Saab's defense contracts. This collaborative approach helps to proactively address any potential supply chain disruptions.

-

Utilizing data analytics to predict potential supply chain disruptions and proactively mitigate risks: Saab employs advanced data analytics tools to monitor its supply chain for potential risks, such as geopolitical instability or natural disasters. This proactive approach allows Saab to anticipate and mitigate potential disruptions, ensuring a continuous flow of materials and minimizing delays in delivery times for military contracts. The use of AI-powered predictive analytics allows for a more dynamic and responsive supply chain management strategy.

-

Implementing just-in-time inventory management techniques to reduce storage costs and optimize workflow: By implementing just-in-time inventory management, Saab minimizes the amount of inventory held in storage, reducing storage costs and optimizing workflow. This approach requires precise coordination with suppliers but ensures that materials arrive exactly when needed, minimizing warehousing expenses and optimizing production processes.

Enhanced Production Processes

Improvements in Saab's manufacturing processes are another key factor contributing to faster order fulfillment. The company has invested heavily in modernizing its production facilities and adopting best-in-class manufacturing practices:

-

Investing in automation and robotics to increase production speed and accuracy: Saab has significantly invested in automation and robotics to enhance production efficiency. Automated production lines and robotic systems increase production speed and accuracy, reducing human error and improving overall output for the production of weapon systems and other military equipment.

-

Implementing lean manufacturing principles to eliminate waste and improve efficiency: By adopting lean manufacturing principles, Saab has eliminated waste in its production processes, streamlining workflows and maximizing efficiency. This reduction in waste contributes directly to shorter lead times and faster delivery of defense orders.

-

Strengthening quality control measures to minimize rework and delays: Rigorous quality control measures are implemented throughout the manufacturing process. This minimizes the need for rework, which can cause significant delays. Saab's commitment to quality ensures that products meet the highest standards and are delivered on time.

-

Utilizing advanced simulation software to optimize production workflows: Saab employs advanced simulation software to model and optimize its production workflows, identifying and eliminating bottlenecks. This enables the company to continuously improve its production processes and achieve even greater efficiency in fulfilling defense orders. The company reports an increase in production by 15% since implementing these strategies.

Improved Collaboration and Communication

Effective communication and collaboration are vital for achieving optimal delivery times. Saab has made significant strides in improving both internal and external communication:

-

Implementing improved project management tools and techniques for better coordination: Saab utilizes sophisticated project management software and methodologies to ensure seamless coordination between different departments and teams involved in fulfilling defense orders. This enhanced coordination streamlines the entire process, reducing delays and improving overall efficiency.

-

Strengthening communication channels with customers to ensure clear expectations and timely feedback: Open and transparent communication with customers is a priority. Saab ensures clear expectations are set regarding timelines and deliverables, with regular updates and feedback provided throughout the process. This fosters strong customer relationships and builds trust.

-

Improving internal communication to ensure seamless collaboration between different departments: Efficient internal communication ensures seamless collaboration between engineering, procurement, production, and logistics departments. Saab uses digital communication platforms to facilitate rapid information exchange, reducing delays and improving coordination.

-

Utilizing digital communication platforms for faster information exchange: Digital communication platforms such as collaborative workspaces and instant messaging tools enable faster and more efficient information exchange between teams and stakeholders, improving overall project management and reducing delays.

Conclusion

Saab's improved delivery times for defense orders are a testament to its commitment to efficiency, innovation, and customer satisfaction. Through strategic investments in supply chain optimization, enhanced production processes, and improved collaboration, Saab has significantly reduced lead times, ultimately strengthening its competitive edge in the global defense market. These improvements benefit not only Saab but also its customers who receive critical defense systems faster, contributing to improved national security and international defense cooperation.

Call to Action: Learn more about Saab's commitment to providing faster and more reliable delivery of defense orders. Contact us today to discuss your defense procurement needs and experience the benefits of improved delivery times with Saab.

Featured Posts

-

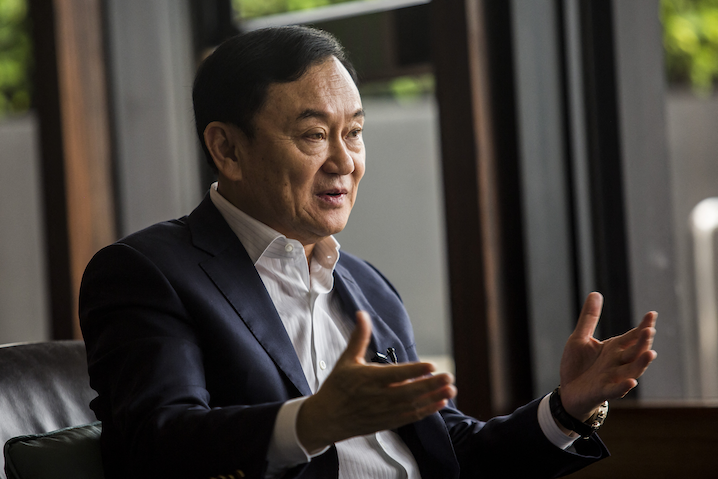

Will Thaksins Influence Lead To A New Era Of Us Thai Trade Agreements

Apr 26, 2025

Will Thaksins Influence Lead To A New Era Of Us Thai Trade Agreements

Apr 26, 2025 -

Deion Sanders Shedeur Sanders Draft Stock Espn Analyst Weighs In

Apr 26, 2025

Deion Sanders Shedeur Sanders Draft Stock Espn Analyst Weighs In

Apr 26, 2025 -

New Hanoi To Hai Phong Luxury Train Service Set For May Debut

Apr 26, 2025

New Hanoi To Hai Phong Luxury Train Service Set For May Debut

Apr 26, 2025 -

Amanda Seyfrieds F Bomb Response To Nepo Baby Backlash

Apr 26, 2025

Amanda Seyfrieds F Bomb Response To Nepo Baby Backlash

Apr 26, 2025 -

George Santos Doj Seeks 87 Month Prison Sentence

Apr 26, 2025

George Santos Doj Seeks 87 Month Prison Sentence

Apr 26, 2025

Latest Posts

-

Ariana Grandes New Hair And Tattoos A Professionals Perspective

Apr 27, 2025

Ariana Grandes New Hair And Tattoos A Professionals Perspective

Apr 27, 2025 -

Ariana Grandes Bold New Look A Guide To Professional Hair And Tattoo Services

Apr 27, 2025

Ariana Grandes Bold New Look A Guide To Professional Hair And Tattoo Services

Apr 27, 2025 -

Hair And Tattoo Transformations Ariana Grandes Professional Stylists

Apr 27, 2025

Hair And Tattoo Transformations Ariana Grandes Professional Stylists

Apr 27, 2025 -

Celebrity Style Transformation Ariana Grandes Hair And Tattoos

Apr 27, 2025

Celebrity Style Transformation Ariana Grandes Hair And Tattoos

Apr 27, 2025 -

Understanding Ariana Grandes New Look Hair Tattoos And Professional Styling

Apr 27, 2025

Understanding Ariana Grandes New Look Hair Tattoos And Professional Styling

Apr 27, 2025