Rethinking Electric Motor Supply Chains: An Alternative To China's Dominance

Table of Contents

The Current State of Electric Motor Manufacturing and China's Influence

China's influence on electric motor production is deeply entrenched. Their market share isn't just significant; it's dominant across various motor types. They hold a particularly strong position in the production of rare earth magnets, essential for many high-performance electric motors, and dominate the manufacturing of specific motor types crucial for certain industries. This dominance stems from several factors:

- High production volumes: China's manufacturing prowess allows for economies of scale, driving down production costs.

- Access to raw materials: Proximity to raw material sources reduces transportation costs and lead times.

- Lower labor costs: Historically lower labor costs have provided a significant competitive advantage.

- Government support and investment: Substantial government subsidies and investment in infrastructure have fueled the growth of the electric motor industry within China.

This combination of factors has resulted in a complex and deeply integrated ecosystem for electric motor manufacturing within China, making it a challenging landscape for competitors to navigate.

Risks of Over-Reliance on a Single Source for Electric Motors

Concentrating electric motor production in one country creates significant vulnerabilities. The potential consequences of disruptions are far-reaching:

- Supply chain disruptions: Any geopolitical event, natural disaster, or pandemic in China could severely impact global electric motor supplies, leading to production halts and shortages across numerous industries.

- Geopolitical risks: Trade disputes or escalating tensions between nations could easily disrupt the flow of electric motors, impacting global markets and national economies.

- Price volatility: Dependence on a single source leaves buyers vulnerable to price fluctuations dictated by the supplier.

- Intellectual property concerns: Concerns about intellectual property protection and potential theft add another layer of risk for companies relying heavily on Chinese manufacturers.

The recent global chip shortage serves as a stark reminder of how reliant the world is on concentrated manufacturing hubs and the devastating impact disruptions can have. The same principles apply to electric motor supply chains, underscoring the urgency of diversification.

Strategies for Diversifying Electric Motor Supply Chains

Diversifying electric motor supply chains requires a multifaceted approach:

- Nearshoring and reshoring initiatives: Relocating manufacturing closer to home or bringing it back to the home country can mitigate risks associated with long supply chains and geopolitical uncertainties. This involves investing in domestic manufacturing capacity and infrastructure.

- Investing in automation and robotics: Automation can reduce reliance on low-cost labor, making production in higher-wage countries more competitive. This also increases efficiency and improves quality control.

- Strategic partnerships and joint ventures: Collaborating with manufacturers in different countries can create more resilient and geographically diverse supply chains.

- Government incentives and support for domestic manufacturing: Government policies, including tax breaks and subsidies, can incentivize domestic production and attract investment in the electric motor sector.

- Developing sustainable sourcing of raw materials: Securing reliable access to raw materials, including rare earth elements, is crucial for long-term supply chain stability. This often involves developing alternative sources and exploring sustainable mining and processing techniques.

The Role of Technology and Innovation in Reshaping Electric Motor Supply Chains

Technological advancements are crucial for reshaping electric motor supply chains:

- Advancements in motor design (e.g., higher efficiency, lower energy consumption): Innovations leading to more efficient and durable motors can reduce reliance on high-volume production and improve overall system performance.

- Additive manufacturing (3D printing) for customized motors: 3D printing offers the potential to manufacture customized motors on demand, reducing reliance on large-scale inventory and enabling faster prototyping and adaptation to evolving needs.

- Smart factories and Industry 4.0 technologies: Implementing smart factory technologies and Industry 4.0 principles can optimize production processes, enhance efficiency, and improve overall supply chain visibility.

- Sustainable materials and manufacturing processes: Adopting sustainable manufacturing practices, utilizing recycled materials, and reducing waste can not only improve the environmental impact but also enhance the long-term sustainability of the electric motor supply chain.

Building a Resilient Future: Reimagining Electric Motor Supply Chains

Rethinking electric motor supply chains is essential for a secure and sustainable future. The challenges are significant, requiring investments in technology, infrastructure, and strategic partnerships. However, the opportunities are equally compelling: a diversified, resilient supply chain will provide greater stability, reduced vulnerability to geopolitical risks, and increased opportunities for innovation. Rethinking your electric motor supply chain is crucial for a secure and sustainable future. Start exploring alternative sourcing strategies today!

Featured Posts

-

How Stefano Domenicalis Leadership Drives Formula 1s Expansion

May 05, 2025

How Stefano Domenicalis Leadership Drives Formula 1s Expansion

May 05, 2025 -

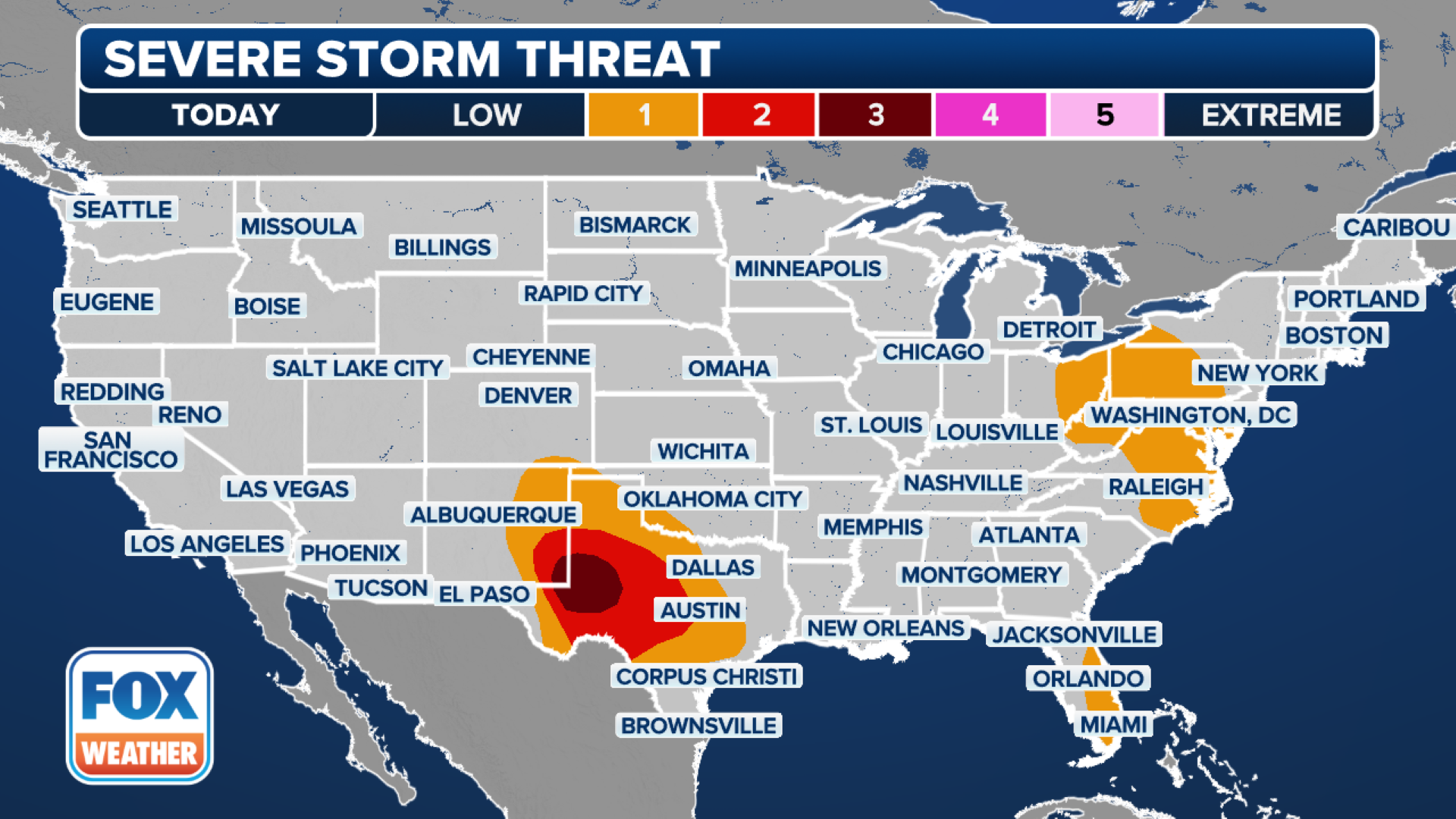

Mondays Severe Weather In Nyc A Detailed Forecast And Guide

May 05, 2025

Mondays Severe Weather In Nyc A Detailed Forecast And Guide

May 05, 2025 -

Analyzing Stefano Domenicalis Influence On Formula 1s Expanding Market

May 05, 2025

Analyzing Stefano Domenicalis Influence On Formula 1s Expanding Market

May 05, 2025 -

Formula 1 Star Max Verstappen Speaks On Fatherhood

May 05, 2025

Formula 1 Star Max Verstappen Speaks On Fatherhood

May 05, 2025 -

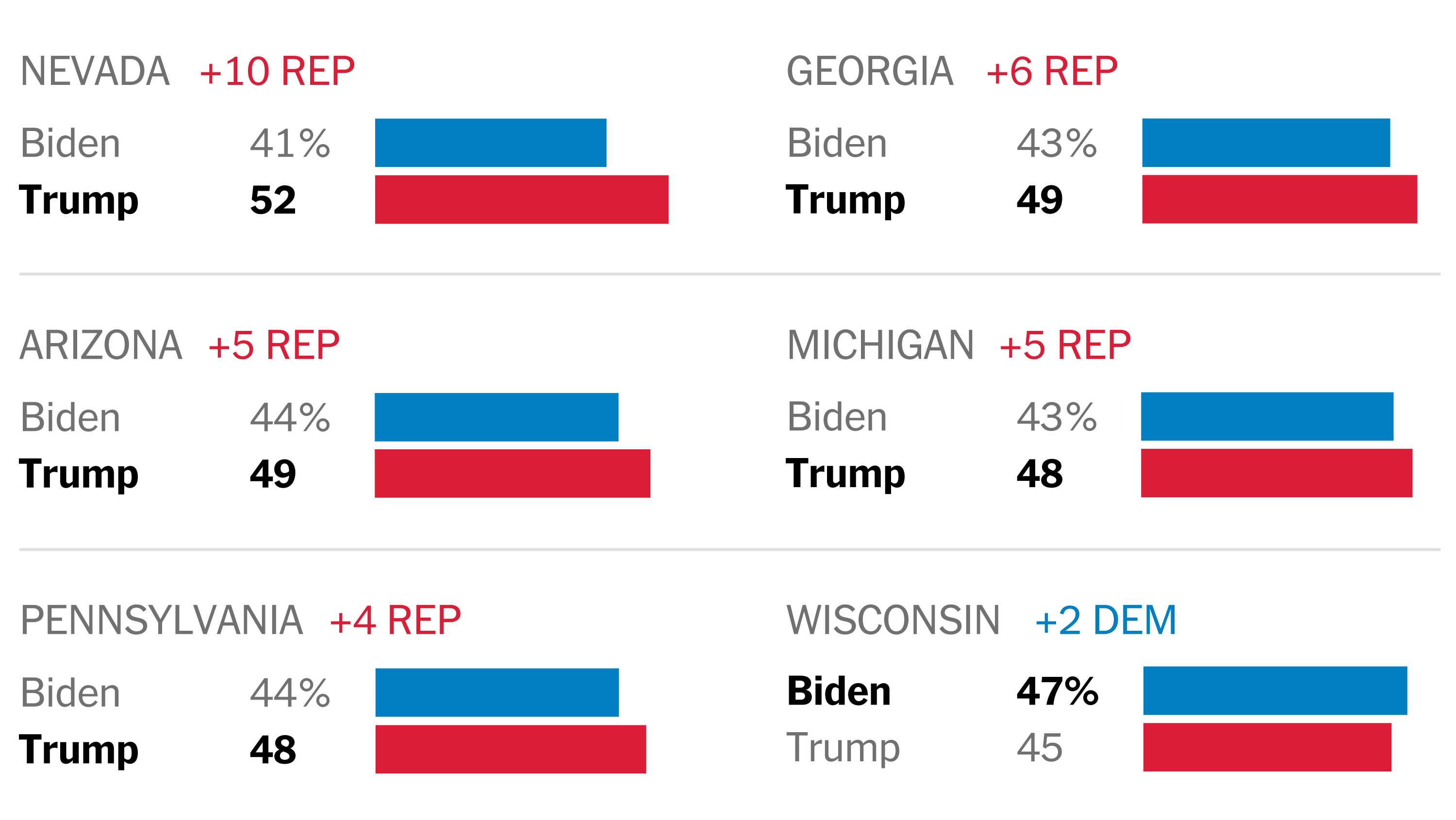

Australia Votes Labor Favored In Latest Election Polls

May 05, 2025

Australia Votes Labor Favored In Latest Election Polls

May 05, 2025

Latest Posts

-

Symmetoxi Emma Stooyn Sto Neo Body Heat

May 05, 2025

Symmetoxi Emma Stooyn Sto Neo Body Heat

May 05, 2025 -

Epistrofi Toy Body Heat I Pithani Symmetoxi Tis Emma Stooyn

May 05, 2025

Epistrofi Toy Body Heat I Pithani Symmetoxi Tis Emma Stooyn

May 05, 2025 -

Body Heat Rimeik I Emma Stooyn Ston Protagonistiko Rolo

May 05, 2025

Body Heat Rimeik I Emma Stooyn Ston Protagonistiko Rolo

May 05, 2025 -

Emma Stooyn Vs Margkaret Koyalei Ti Pragmatika Synevi Sta Oskar

May 05, 2025

Emma Stooyn Vs Margkaret Koyalei Ti Pragmatika Synevi Sta Oskar

May 05, 2025 -

Oskar 2024 Diavasame Ta Xeili Tis Emma Stooyn Kai Tis Margkaret Koyalei

May 05, 2025

Oskar 2024 Diavasame Ta Xeili Tis Emma Stooyn Kai Tis Margkaret Koyalei

May 05, 2025