SG Wireless Strengthens Manufacturing Partnerships To Address OEM Supply Chain Challenges

Table of Contents

Strategic Partnerships for Enhanced Component Sourcing

Navigating the complexities of modern component sourcing requires a multifaceted approach. For SG Wireless, this translates to a commitment to strategic supplier diversification and robust supplier relationship management (SRM). Addressing the challenges of the global supply chain head-on, we are implementing several key strategies:

-

Expanding our network of trusted manufacturers: We're actively diversifying our sourcing to reduce reliance on single suppliers. This geographical diversification mitigates risks associated with regional disruptions, political instability, and natural disasters. We've expanded our partnerships to include reputable manufacturers in [mention specific regions, e.g., Southeast Asia, North America, Europe], ensuring a resilient and geographically diverse supply chain.

-

Implementing robust supplier relationship management (SRM) programs: Our SRM programs foster strong, collaborative relationships with our suppliers. This ensures consistent quality, on-time delivery, and proactive communication regarding potential challenges. Regular performance reviews and open communication channels are crucial components of this program.

-

Proactive risk mitigation: We utilize advanced forecasting and contingency planning to identify and mitigate potential supply chain risks. This includes scenario planning for various disruptions, securing alternative sources for critical components, and maintaining sufficient safety stock levels. Our risk assessment process identifies potential vulnerabilities early, allowing us to implement preventative measures.

-

Securing access to critical raw materials and electronic components: We're establishing long-term agreements with key suppliers to secure access to critical raw materials and electronic components. These agreements provide price stability and guarantee the availability of essential resources, even in times of high demand.

-

Collaborative efficiency improvements: We're actively collaborating with our suppliers to optimize processes, improve efficiency, and reduce lead times. This collaborative approach fosters innovation and leads to mutual benefits, including reduced costs and improved product quality. For example, our collaboration with [Supplier Name] resulted in a 15% reduction in lead times for [specific component].

Investing in Manufacturing Capacity and Technology

Beyond strengthening partnerships, SG Wireless is significantly investing in its manufacturing capabilities and technology. This commitment to advanced manufacturing ensures we can meet the increasing demands of our OEM clients while maintaining our high standards of quality and efficiency. Our investments focus on:

-

Upgrading manufacturing facilities: We're integrating cutting-edge technologies across our facilities to enhance production efficiency and quality control. This includes the implementation of [mention specific technologies, e.g., automated assembly lines, advanced testing equipment].

-

Automation for consistency: Implementing automation solutions reduces our reliance on manual labor, improving process consistency and reducing human error. This automation is not only about efficiency; it's about ensuring consistent quality across all our products.

-

Advanced quality control systems: We've invested in robust quality control systems to ensure consistently high standards across all production processes. This includes rigorous testing at every stage of production and the implementation of advanced quality management systems (QMS).

-

Expanded manufacturing capacity: We've expanded our manufacturing capacity to meet growing customer demand and accommodate fluctuations in market conditions. This expansion allows us to respond quickly to changes in market dynamics and ensure timely delivery.

-

Sustainable manufacturing practices: We are committed to sustainable and environmentally responsible manufacturing practices. This commitment includes implementing energy-efficient technologies and reducing our environmental footprint.

Strengthening Collaboration with OEM Clients

Open communication and strong relationships are the foundation of a resilient supply chain. For SG Wireless, strengthening collaboration with our OEM clients is paramount. We achieve this through:

-

Improved demand forecasting: We're enhancing communication with our OEM clients to improve the accuracy of our demand forecasting. This collaborative approach ensures we have the necessary resources to meet our clients' needs.

-

Supply chain transparency: We increase supply chain transparency through real-time data sharing and regular progress updates. This keeps our clients informed and allows us to proactively address any potential issues. Our online portal provides clients with 24/7 access to real-time data on their orders.

-

Proactive bottleneck resolution: We work closely with our OEM clients to identify and resolve supply chain bottlenecks proactively. Early identification allows us to implement effective mitigation strategies.

-

Flexible solutions: We provide flexible solutions to meet evolving customer needs and changing market demands. This adaptability ensures we remain a reliable partner, even amidst market uncertainties.

-

Long-term, trusted partnerships: We focus on building long-term relationships based on trust and mutual success. These strong relationships form the bedrock of our collaborative approach to supply chain management.

Conclusion

By strengthening our manufacturing partnerships and investing in advanced technologies, SG Wireless is bolstering its resilience against ongoing OEM supply chain challenges. This strategic approach ensures the continued delivery of high-quality products, on time and in full, to our valued clients. Our commitment to collaboration and proactive risk management positions us to navigate future uncertainties and maintain a strong competitive advantage. Are you an OEM facing supply chain disruptions? Partner with SG Wireless for reliable and resilient wireless solutions. Contact us today to discuss your needs and learn how our robust manufacturing partnerships can support your success.

Featured Posts

-

World Renowned Architect On Virtue Signalling And Professional Challenges

May 26, 2025

World Renowned Architect On Virtue Signalling And Professional Challenges

May 26, 2025 -

Is Fascism Rising Delaware Governors Warning On The Post Biden Landscape

May 26, 2025

Is Fascism Rising Delaware Governors Warning On The Post Biden Landscape

May 26, 2025 -

Southern Vacation Area Addresses Safety Concerns Post Shooting Incident

May 26, 2025

Southern Vacation Area Addresses Safety Concerns Post Shooting Incident

May 26, 2025 -

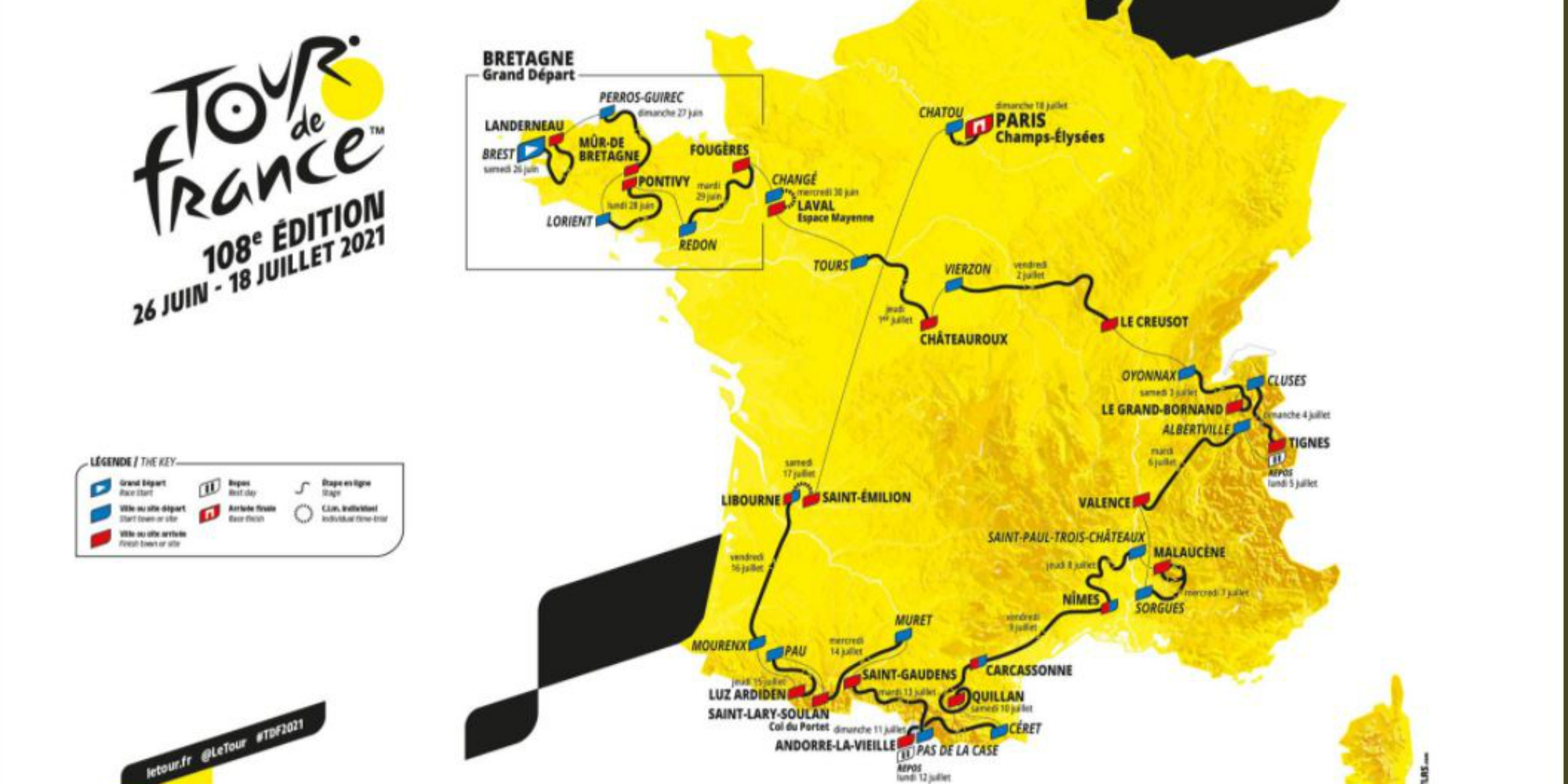

Le Jeu Officiel Du Tour De France Une Experience De Management Cycliste Par La Rtbf

May 26, 2025

Le Jeu Officiel Du Tour De France Une Experience De Management Cycliste Par La Rtbf

May 26, 2025 -

Alqbd Ela Ashhr Mjrm Harb Fy Frnsa Bthmt Qtl Eaylth Wdfnhm

May 26, 2025

Alqbd Ela Ashhr Mjrm Harb Fy Frnsa Bthmt Qtl Eaylth Wdfnhm

May 26, 2025