The Big Rig ROCK Report 3.12: Practical Applications In Rock 101

Table of Contents

Understanding Rock Mass Classification Systems (RMR, Q-system)

Accurate rock mass classification is fundamental to geotechnical engineering. Two widely used systems are the Rock Mass Rating (RMR) and the Q-system. These systems consider various parameters to quantify the overall strength and behavior of a rock mass. Key parameters include the Rock Quality Designation (RQD), joint spacing, joint conditions (roughness, weathering, infilling), and the intact rock strength. The Geological Strength Index (GSI) is also often incorporated, reflecting the overall quality of the rock mass.

- Determining RQD from core logging: RQD is calculated from the percentage of intact core pieces longer than 10cm in a drill core sample. Accurate core logging is critical for determining this value.

- Influence of joint orientation and persistence: The orientation of discontinuities (joints, faults, fractures) significantly influences rock mass stability. Persistent, steeply dipping joints can lead to slope instability, while closely spaced joints reduce overall strength.

- RMR and Q-system values in engineering design: The RMR and Q-system values provide quantitative estimates of rock mass quality. These values directly inform engineering design decisions related to support systems, excavation methods, and slope stability analysis. Higher values indicate stronger, more stable rock masses.

- Real-world examples: The Big Rig ROCK Report 3.12 includes numerous examples demonstrating the application of RMR and Q-system classifications in diverse projects, ranging from tunnel design to dam construction.

Practical Applications in Slope Stability Analysis

Rock slope stability is a critical concern in many engineering projects. The Big Rig ROCK Report 3.12 provides valuable insights into analyzing potential failure mechanisms in rock slopes. This analysis relies heavily on understanding rock mass properties and the influence of geological structures.

- Common failure modes: Rock slopes can fail through various mechanisms, including toppling (overturning of rock blocks), sliding (movement along a planar or curved surface), and wedge failure (failure of a wedge-shaped rock mass).

- Limit equilibrium methods: These methods are widely used for analyzing slope stability, calculating the factor of safety (the ratio of resisting forces to driving forces). The Big Rig ROCK Report 3.12 provides guidance on applying these methods effectively.

- Rock support systems: Effective rock support systems, such as rock bolts, shotcrete, and retaining walls, are crucial for stabilizing unstable slopes. The report illustrates how to select appropriate support measures based on the characteristics of the rock mass.

- Case studies of slope failures and mitigation: The report presents case studies detailing real-world slope failures and the successful implementation of mitigation strategies, providing valuable lessons for future projects.

Excavation and Blasting Techniques in Rock

Efficient and safe rock excavation often relies on blasting techniques. Understanding rock properties is crucial for optimizing blasting designs and minimizing environmental impact. The Big Rig ROCK Report 3.12 offers guidance on selecting appropriate blasting techniques and controlling vibrations.

- Drilling techniques: Various drilling techniques are employed depending on the rock type and project requirements. The report provides insights into selecting optimal drilling patterns.

- Explosive selection: The type and amount of explosives used depend on rock strength and desired fragmentation size. The Big Rig ROCK Report 3.12 helps determine suitable explosives based on rock properties and project specifications.

- Controlling blasting vibrations: Blasting can generate vibrations that could damage surrounding structures. The report details methods for controlling vibrations, including optimizing blasting designs and using vibration monitoring equipment.

- Fragmentation analysis: Analyzing the size distribution of blasted rock fragments is important for optimizing blasting operations and minimizing downstream processing costs. The report helps with understanding fragmentation analysis techniques.

Case Studies: Real-world Examples from the Big Rig ROCK Report 3.12

The Big Rig ROCK Report 3.12 is rich with real-world case studies showcasing the practical application of rock mechanics principles. These examples highlight the value of the report in solving complex engineering challenges.

- Project descriptions: The report includes concise descriptions of several projects, emphasizing the geological context and engineering challenges.

- Challenges and solutions: Each case study illustrates specific challenges faced and how the application of rock mechanics principles led to successful solutions.

- Positive outcomes: The report demonstrates the positive outcomes, such as improved safety, cost savings, and project efficiency, achieved by applying the principles outlined in the report.

Conclusion

The Big Rig ROCK Report 3.12 provides an invaluable resource for understanding and applying rock mechanics principles. The report's practical applications in slope stability analysis, excavation, and blasting techniques are crucial for success in Rock 101 and beyond. Mastering these fundamentals is essential for any aspiring or practicing geologist or engineer working with rock masses. Master the fundamentals of rock mechanics and unlock your potential with the Big Rig ROCK Report 3.12. Download the report today and elevate your Rock 101 knowledge to the next level!

Featured Posts

-

Ranking Pete Townshends Solo Albums From Worst To Best

May 23, 2025

Ranking Pete Townshends Solo Albums From Worst To Best

May 23, 2025 -

Find Cat Deeleys Mint Velvet Dress Liverpool One Shopping Guide

May 23, 2025

Find Cat Deeleys Mint Velvet Dress Liverpool One Shopping Guide

May 23, 2025 -

Swiss Village Faces Landslide Livestock Evacuated By Hoof And Helicopter

May 23, 2025

Swiss Village Faces Landslide Livestock Evacuated By Hoof And Helicopter

May 23, 2025 -

Makedoni A Gi Dozna Protivnitsite Vo Ligata Na Natsii Shto Ochekuvame

May 23, 2025

Makedoni A Gi Dozna Protivnitsite Vo Ligata Na Natsii Shto Ochekuvame

May 23, 2025 -

Mexico Vs Panama Hora Canal Y Donde Ver La Final De La Liga De Naciones Concacaf

May 23, 2025

Mexico Vs Panama Hora Canal Y Donde Ver La Final De La Liga De Naciones Concacaf

May 23, 2025

Latest Posts

-

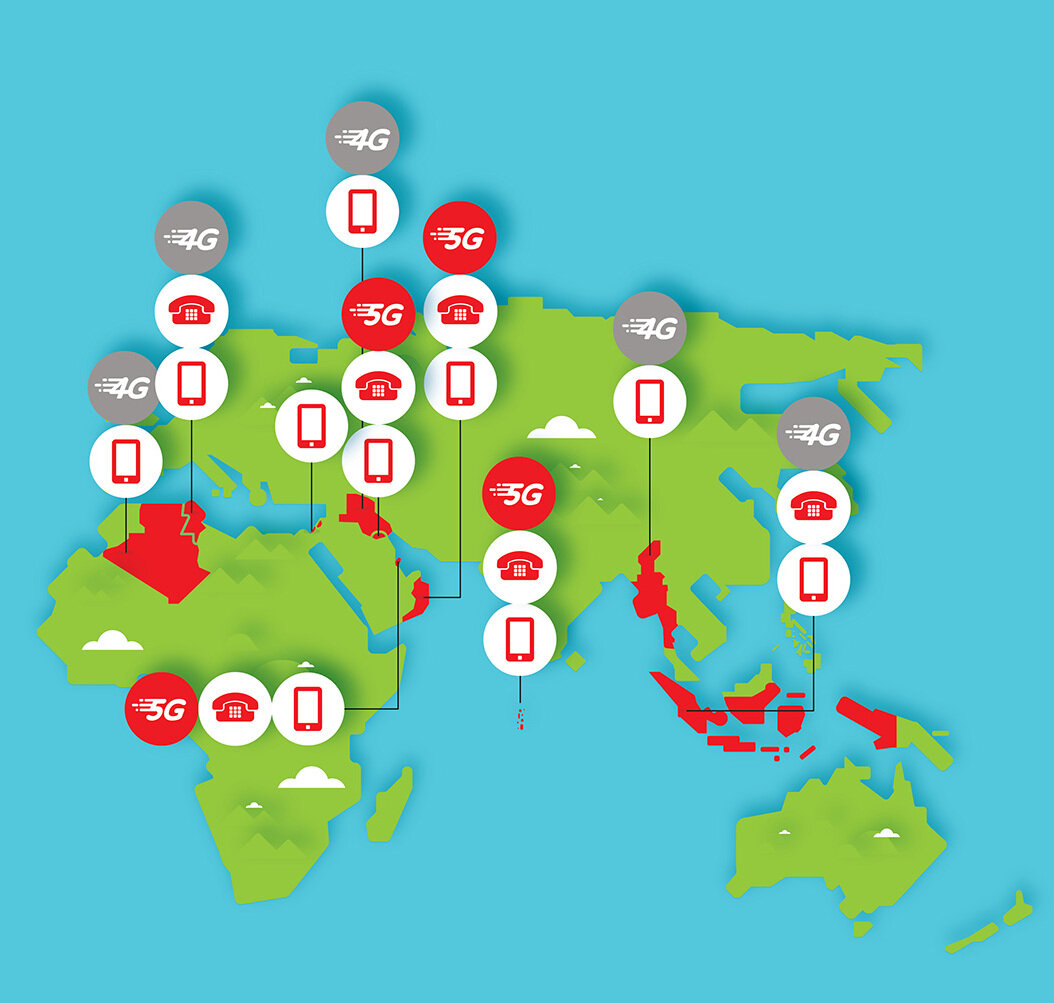

Ooredoo Qatar And Qtspbf Renewed Commitment To Collaboration

May 23, 2025

Ooredoo Qatar And Qtspbf Renewed Commitment To Collaboration

May 23, 2025 -

Extended Partnership Ooredoo Qatar And Qtspbf On Continued Success

May 23, 2025

Extended Partnership Ooredoo Qatar And Qtspbf On Continued Success

May 23, 2025 -

Strengthening Ties Ooredoo Qatar And Qtspbf Extend Collaboration

May 23, 2025

Strengthening Ties Ooredoo Qatar And Qtspbf Extend Collaboration

May 23, 2025 -

Ooredoo And Qtspbf A Winning Partnership Continues

May 23, 2025

Ooredoo And Qtspbf A Winning Partnership Continues

May 23, 2025 -

Ooredoo Qatar And Qtspbf Extend Successful Partnership

May 23, 2025

Ooredoo Qatar And Qtspbf Extend Successful Partnership

May 23, 2025