The High Cost Of All-American Manufacturing

Table of Contents

The High Cost of Labor in All-American Manufacturing

Higher wages, comprehensive benefits, and skilled labor shortages significantly impact the cost-competitiveness of All-American manufacturing. Let's delve into the specifics:

Higher Wages and Benefits

American workers enjoy significantly higher wages and more comprehensive benefits packages than their counterparts in many other manufacturing nations.

- Healthcare: Employer-sponsored health insurance is a significant expense in the US, often exceeding costs in countries with universal healthcare systems.

- Retirement: Matching contributions to 401(k) plans and other retirement benefits further increase labor costs.

- Paid Time Off: Generous vacation and sick leave policies are standard in many US workplaces, adding to the overall labor expense.

A comparison of average manufacturing wages reveals a stark contrast. The average hourly wage for a manufacturing worker in the US is significantly higher than in countries like China or Mexico, directly impacting production costs. Data from the Bureau of Labor Statistics consistently shows this disparity, making domestic manufacturing more expensive.

Skill Shortages and Training Costs

Finding skilled workers in the US manufacturing sector is an ongoing challenge. The skills gap necessitates substantial investments in training programs.

- In-demand skills: Advanced manufacturing requires expertise in robotics, automation, and data analytics, creating a need for specialized training.

- Apprenticeship programs: While effective, apprenticeship programs require significant time and financial investment, adding to the overall cost of employing skilled labor.

- On-the-job training: Even experienced workers often require additional training to adapt to new technologies and processes, adding to the cost burden.

The US currently faces a substantial number of unfilled manufacturing jobs, highlighting the challenge of finding and training a qualified workforce. This shortage directly impacts production capacity and drives up the cost of All-American manufacturing.

Regulatory Burden and Compliance Costs in All-American Manufacturing

Stringent environmental and safety regulations, while crucial for protecting workers and the environment, add considerable costs to domestic manufacturing.

Environmental Regulations

The US boasts some of the strictest environmental regulations globally.

- Clean Air Act & Clean Water Act: Adherence to these acts necessitates substantial investments in pollution control equipment and ongoing monitoring, increasing operational expenses.

- Waste disposal: Proper and responsible waste disposal adds another layer of cost to manufacturing processes.

- Permitting and reporting: Obtaining and maintaining environmental permits involves significant administrative costs and ongoing reporting requirements.

Studies have shown that environmental compliance represents a considerable portion of the overall cost for US manufacturers, making them less competitive internationally.

Safety Regulations and Worker Protections

Robust worker safety regulations and comprehensive worker's compensation systems contribute to the high cost of All-American manufacturing.

- Occupational Safety and Health Administration (OSHA) standards: Meeting OSHA's rigorous safety standards requires investments in safety equipment, training, and preventative measures.

- Workers' compensation insurance: Premiums for workers' compensation insurance, designed to protect employees injured on the job, represent a significant expense for manufacturers.

- Safety training: Regular and comprehensive safety training for employees is a necessary cost, contributing to the overall labor expense.

The high cost of safety measures and worker protection, while ethically responsible, increases the overall price of manufacturing goods produced in the US.

Infrastructure and Logistics Costs in All-American Manufacturing

Outdated infrastructure and high energy costs present substantial challenges to domestic manufacturers.

Aging Infrastructure

The condition of America's infrastructure directly affects transportation costs and production efficiency.

- Road conditions: Poor road conditions lead to increased transportation times and higher fuel costs, impacting the cost of moving goods to market.

- Port congestion: Overcrowded ports cause delays, increasing storage costs and impacting timely delivery.

- Energy grid reliability: An aging energy grid can lead to disruptions and higher energy costs for manufacturers.

Investing in infrastructure improvements is crucial to reducing these logistics costs and enhancing the competitiveness of All-American manufacturing.

Energy Costs

The US often faces higher energy prices compared to some other manufacturing nations.

- Electricity costs: Higher electricity costs directly impact the operational expenses of energy-intensive manufacturing processes.

- Natural gas prices: Fluctuations in natural gas prices, a key energy source for many manufacturers, contribute to cost instability.

- Energy efficiency: While investments in energy efficiency can help mitigate costs, the initial investment can be substantial.

Addressing energy costs, through investment in renewable energy or energy-efficient technologies, is crucial for lowering the overall cost of All-American manufacturing.

Supply Chain Challenges and Material Costs in All-American Manufacturing

Sourcing raw materials domestically and competing in the global market adds another layer of complexity and cost.

Sourcing Domestic Materials

Relying on domestically sourced raw materials can present challenges.

- Limited supply: The availability of certain raw materials may be limited within the US, driving up prices.

- Transportation costs: Transporting materials across the country can be expensive, adding to the overall cost of production.

- Price volatility: Prices for domestically sourced raw materials can be volatile, creating uncertainty for manufacturers.

Global Competition and Tariffs

The globalized manufacturing landscape presents significant competitive pressures.

- International competition: Manufacturers in other countries often have lower labor and regulatory costs, making them more competitive.

- Tariffs and trade wars: Tariffs imposed on imported goods can increase the cost of raw materials and components, while impacting export opportunities.

- Global supply chains: Disruptions to global supply chains, as seen recently, can significantly impact domestic manufacturers' ability to source necessary materials.

Navigating global trade dynamics and fostering a more resilient domestic supply chain is critical for ensuring the cost-competitiveness of All-American manufacturing.

Conclusion: Navigating the High Cost of All-American Manufacturing – A Call to Action

The high cost of All-American manufacturing is a complex issue stemming from a confluence of factors: higher labor costs, stringent regulations, aging infrastructure, and global supply chain complexities. While the benefits of domestic production are undeniable – including job creation, national security, and reduced reliance on foreign supply chains – addressing the high cost is paramount. To revitalize American manufacturing and foster its growth, a multifaceted approach is required. This includes significant investments in modernizing infrastructure, implementing targeted tax incentives to encourage domestic production, and fostering robust skills training programs to bridge the labor skills gap. Let's work together to find innovative solutions to lower the high cost of All-American manufacturing and ensure a vibrant future for American industry. Investing in solutions to reduce the cost of All-American manufacturing is essential for the future of our economy.

Featured Posts

-

Post Roe America How Otc Birth Control Changes The Game

Apr 29, 2025

Post Roe America How Otc Birth Control Changes The Game

Apr 29, 2025 -

Trump Administrations Threat To Cut Federal Funds Harvards Legal Response

Apr 29, 2025

Trump Administrations Threat To Cut Federal Funds Harvards Legal Response

Apr 29, 2025 -

Louisville Restaurants Struggle Amid River Road Construction

Apr 29, 2025

Louisville Restaurants Struggle Amid River Road Construction

Apr 29, 2025 -

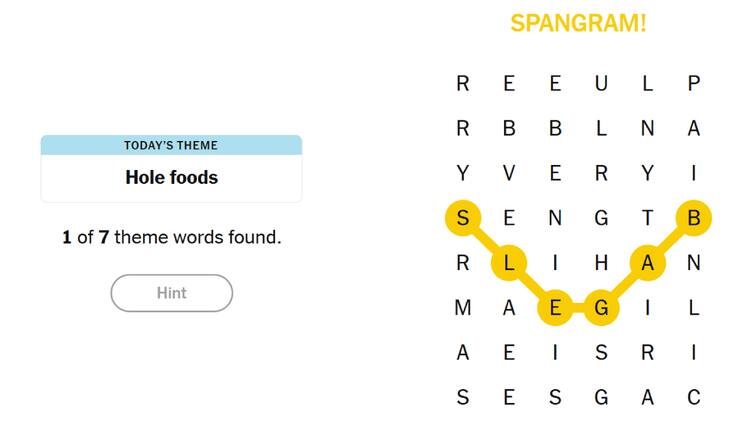

Nyt Spelling Bee February 12 2025 Complete Solution And Spangram

Apr 29, 2025

Nyt Spelling Bee February 12 2025 Complete Solution And Spangram

Apr 29, 2025 -

How You Tube Caters To The Preferences Of Older Viewers

Apr 29, 2025

How You Tube Caters To The Preferences Of Older Viewers

Apr 29, 2025

Latest Posts

-

Older Viewers And You Tube A Growing Trend

Apr 29, 2025

Older Viewers And You Tube A Growing Trend

Apr 29, 2025 -

Why Older Adults Are Choosing You Tube For Entertainment

Apr 29, 2025

Why Older Adults Are Choosing You Tube For Entertainment

Apr 29, 2025 -

You Tubes Growing Popularity Among Older Viewers

Apr 29, 2025

You Tubes Growing Popularity Among Older Viewers

Apr 29, 2025 -

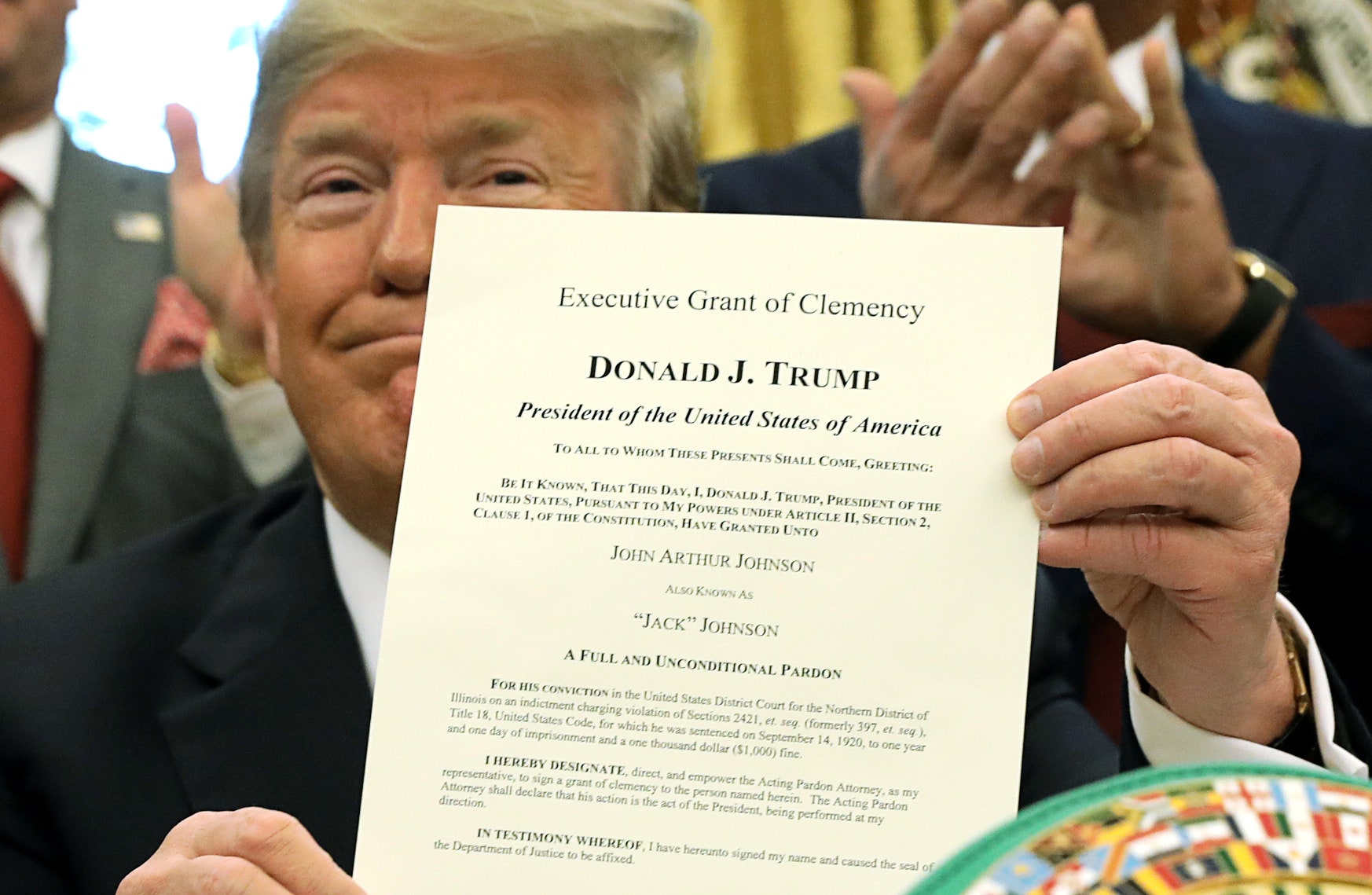

Full Pardon For Rose Trumps Decision And Its Fallout

Apr 29, 2025

Full Pardon For Rose Trumps Decision And Its Fallout

Apr 29, 2025 -

Rose Pardon Will Trump Grant Executive Clemency

Apr 29, 2025

Rose Pardon Will Trump Grant Executive Clemency

Apr 29, 2025