The Truck Bloat Problem: Potential Solutions And Their Effectiveness

Table of Contents

Understanding the Causes of Truck Bloat

Truck bloat, characterized by decreased fuel efficiency and increased operational costs, stems from a combination of factors. Addressing these root causes is crucial for effective mitigation.

Inefficient Routing and Planning

Poor route optimization is a major contributor to truck bloat. Unnecessary mileage, excessive idling, and wasted fuel directly translate to higher operational expenses.

- Lack of real-time traffic data integration: Failing to incorporate real-time traffic information into route planning leads to delays and increased fuel consumption.

- Failure to utilize route planning software: Relying on outdated methods or guesswork significantly impacts efficiency and increases the risk of encountering unexpected delays. Modern route planning software considers various factors like traffic, road conditions, and delivery schedules for optimal routes.

- Ignoring driver feedback on route efficiency: Drivers often possess valuable insights into local road conditions and potential shortcuts. Ignoring their feedback limits optimization opportunities.

- Insufficient training on fuel-efficient driving techniques: Driver training plays a vital role in minimizing fuel waste. Educating drivers about techniques like smooth acceleration and braking significantly impacts fuel economy.

Suboptimal Vehicle Maintenance

Neglecting regular maintenance directly contributes to truck bloat by increasing fuel consumption and reducing overall vehicle efficiency.

- Delayed or skipped preventative maintenance checks: Preventative maintenance is key to preventing major breakdowns and ensuring optimal vehicle performance. Skipping these checks leads to increased downtime and repair costs.

- Ignoring tire pressure and condition: Proper tire inflation is crucial for fuel efficiency and tire longevity. Underinflation significantly increases rolling resistance and fuel consumption.

- Lack of engine tune-ups and cleaning: Regular engine tune-ups and cleaning optimize engine performance and fuel efficiency. Neglecting this can lead to increased fuel consumption and potential engine damage.

- Overlooking brake system issues: Brake system problems can lead to increased fuel consumption and reduced stopping power, posing a safety risk.

Driver Behavior and Habits

Aggressive driving styles and poor driving habits significantly impact fuel efficiency and contribute to truck bloat.

- Excessive speeding and rapid acceleration: Aggressive driving consumes significantly more fuel than smooth, steady driving.

- Frequent hard braking: Hard braking wastes energy and increases wear and tear on brake components.

- Idling for extended periods: Idling consumes fuel without any productive output. Minimize idling time whenever possible.

- Improper load distribution affecting aerodynamics: Improper load distribution increases wind resistance, leading to higher fuel consumption.

Potential Solutions to Combat Truck Bloat

Several effective solutions can significantly reduce or eliminate truck bloat. Implementing these strategies requires a multifaceted approach.

Implementing Advanced Telematics

Utilizing GPS tracking and fleet management software provides real-time data for improved route optimization and driver monitoring.

- Real-time traffic updates and rerouting capabilities: Telematics systems provide real-time traffic information, allowing for dynamic route adjustments to avoid congestion and delays.

- Driver behavior monitoring and performance analysis: Tracking driver behavior allows for identification of areas for improvement in fuel efficiency and driving practices.

- Fuel consumption tracking and identification of inefficient practices: Monitoring fuel consumption helps pinpoint inefficient routes, driving styles, and vehicle maintenance issues.

- Predictive maintenance alerts based on vehicle data: Predictive maintenance alerts help prevent breakdowns by identifying potential issues before they occur.

Driver Training and Education

Investing in driver training and education is crucial for improving fuel efficiency and reducing truck bloat.

- Workshops on fuel-efficient driving techniques: Conducting workshops and training sessions on fuel-efficient driving techniques equips drivers with the knowledge and skills to improve their fuel economy.

- Incentive programs for fuel-efficient driving: Implementing incentive programs motivates drivers to adopt fuel-efficient driving habits.

- Regular performance feedback and coaching sessions: Providing regular feedback and coaching sessions helps drivers identify and address areas for improvement.

- Use of simulation software for driver training: Simulation software provides a safe and controlled environment for drivers to practice fuel-efficient driving techniques.

Regular Preventative Maintenance

A robust preventative maintenance schedule is essential for minimizing downtime, extending vehicle lifespan, and reducing operational costs.

- Regular engine checks and servicing: Regular engine checks and servicing ensure optimal engine performance and fuel efficiency.

- Tire pressure monitoring and rotation: Regular tire pressure monitoring and rotation are crucial for maintaining optimal tire condition and fuel efficiency.

- Brake system inspections and repairs: Regular brake system inspections and repairs prevent costly breakdowns and ensure safe operation.

- Regular fluid changes: Regular fluid changes help maintain optimal vehicle performance and prevent potential engine damage.

Evaluating the Effectiveness of Solutions

Measuring the success of implemented solutions is crucial. Tracking key performance indicators (KPIs) is essential for assessing the effectiveness of strategies to combat truck bloat. These KPIs include:

- Fuel consumption per mile: This metric directly reflects the impact of implemented solutions on fuel efficiency.

- Maintenance costs: Tracking maintenance costs helps assess the effectiveness of preventative maintenance programs.

- Overall operational efficiency: This overall measure reflects the combined impact of all implemented solutions on the trucking operation's efficiency.

Continuous monitoring and adjustments are crucial to maintain optimal performance and adapt to changing conditions.

Conclusion

Truck bloat significantly impacts the profitability and efficiency of trucking operations. By addressing its root causes through advanced telematics, comprehensive driver training, and a rigorous preventative maintenance program, trucking businesses can effectively combat this problem. Regularly evaluating the effectiveness of implemented solutions through KPI tracking ensures continuous improvement and maximizes returns. Take control of your fleet's performance and tackle the truck bloat problem today! Implement these strategies and experience the difference in your bottom line. Don't let truck bloat continue to drain your profits – optimize your fleet and drive towards greater efficiency.

Featured Posts

-

Eva Longorias Culinary Encounter A World Class Fishermans Stew

Apr 28, 2025

Eva Longorias Culinary Encounter A World Class Fishermans Stew

Apr 28, 2025 -

Chinas Tariff Exemptions Some Us Goods Get A Break

Apr 28, 2025

Chinas Tariff Exemptions Some Us Goods Get A Break

Apr 28, 2025 -

Ohio Train Derailment Prolonged Exposure To Toxic Chemicals In Buildings

Apr 28, 2025

Ohio Train Derailment Prolonged Exposure To Toxic Chemicals In Buildings

Apr 28, 2025 -

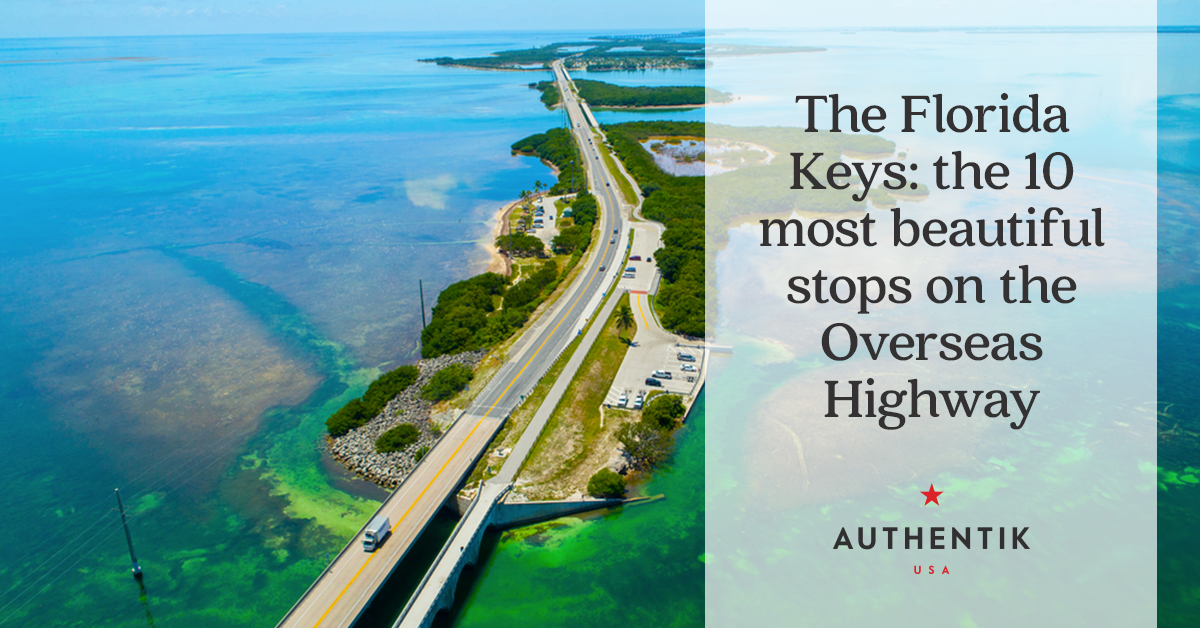

Florida Keys Road Trip A Journey Across The Overseas Highway

Apr 28, 2025

Florida Keys Road Trip A Journey Across The Overseas Highway

Apr 28, 2025 -

Analyzing The Countrys Top Business Locations For 2024 Or Relevant Year

Apr 28, 2025

Analyzing The Countrys Top Business Locations For 2024 Or Relevant Year

Apr 28, 2025

Latest Posts

-

Lingering Effects Toxic Chemicals In Buildings After Ohio Train Derailment

Apr 28, 2025

Lingering Effects Toxic Chemicals In Buildings After Ohio Train Derailment

Apr 28, 2025 -

Ohio Train Derailment Prolonged Exposure To Toxic Chemicals In Buildings

Apr 28, 2025

Ohio Train Derailment Prolonged Exposure To Toxic Chemicals In Buildings

Apr 28, 2025 -

Months Of Toxic Chemical Contamination Following Ohio Train Derailment

Apr 28, 2025

Months Of Toxic Chemical Contamination Following Ohio Train Derailment

Apr 28, 2025 -

Ohio Train Derailment Toxic Chemical Lingering In Buildings Months Later

Apr 28, 2025

Ohio Train Derailment Toxic Chemical Lingering In Buildings Months Later

Apr 28, 2025 -

Understanding The Volatility Of Gpu Prices

Apr 28, 2025

Understanding The Volatility Of Gpu Prices

Apr 28, 2025