Understanding The Big Rig ROCK Report 3.12: A Rock 101 Guide

Table of Contents

Key Concepts Explained in the Big Rig ROCK Report 3.12

The Big Rig ROCK Report 3.12 delves into crucial aspects of rock mechanics, providing a robust framework for assessing rock mass stability. Let's explore some of its core concepts:

Rock Mass Classification Systems

Accurate rock mass classification is fundamental to effective geotechnical engineering. The Big Rig ROCK Report 3.12 extensively covers several established systems, including the widely used RMR (Rock Mass Rating) and Q-system classifications. These systems help quantify the overall strength and stability of a rock mass based on several key parameters.

- RMR Classification: Considers factors such as uniaxial compressive strength, rock quality designation (RQD), spacing of discontinuities, condition of discontinuities, groundwater conditions, and orientation of discontinuities. A higher RMR value indicates a stronger and more stable rock mass.

- Q-system Classification: Employs parameters like RQD, joint spacing, joint roughness, joint alteration, groundwater conditions, and the strength of the intact rock material. The Q-value provides a quantitative assessment of the rock mass quality. A higher Q-value signifies a better rock mass quality.

These systems are not mutually exclusive and are often used in conjunction to provide a more comprehensive assessment. Practical applications range from designing stable slopes in open-pit mines to optimizing tunnel support systems. For instance, the RMR classification helps determine the appropriate support measures for underground excavations, while the Q-system is crucial for designing stable slopes in open-pit mining operations. Understanding both the RMR classification and Q-system classification is vital for informed decision-making in geotechnical projects.

Understanding Rock Strength and Deformability

Rock strength and deformability are critical properties influencing the design and stability of engineering structures. The Big Rig ROCK Report 3.12 details methods for determining these properties:

- Rock Strength: Often determined through laboratory tests like uniaxial compressive strength (UCS) tests and triaxial tests. These tests provide insights into the rock's ability to resist failure under various stress conditions.

- Rock Deformability: Assessed through tests like the elastic modulus determination, which quantifies the rock's stiffness and its response to applied stress. This is crucial for predicting rock mass deformation under load.

The report emphasizes the impact of rock strength on various applications. For example, higher rock strength allows for steeper slopes in open-pit mining and reduces the need for extensive support in tunnel construction. Conversely, low rock strength necessitates careful design considerations, such as reinforced retaining walls or specialized support systems. The rock's deformability influences the design of foundations and underground openings, impacting settlements and overall structural integrity.

Joint Characteristics and Their Influence on Rock Mass Behavior

The Big Rig ROCK Report 3.12 highlights the significant influence of discontinuities, such as joints, fractures, and faults, on rock mass behavior. These discontinuities significantly impact rock mass strength, permeability, and overall stability.

- Joint Orientation: The orientation (dip and dip direction) of joints determines their impact on slope stability. Joints parallel to a slope face can significantly reduce stability.

- Joint Spacing: Closely spaced joints weaken the rock mass, reducing its overall strength.

- Joint Roughness: Rough joints interlock, offering higher shear strength compared to smooth, planar joints.

- Joint Infilling Material: The presence of weak infilling materials (clay, weathered rock) reduces shear strength along the joints.

Characterizing these joints is crucial for accurate rock mass assessment. Methods include detailed field mapping, scan line surveys, and advanced techniques like 3D laser scanning. Understanding the joint roughness coefficient is vital for determining the shear strength of these discontinuities. The impact of joint orientation on slope stability is a crucial consideration in slope design and stability analysis.

Rock Slope Stability Analysis

The Big Rig ROCK Report 3.12 discusses various methods for analyzing rock slope stability. These methods aim to assess the likelihood of failure and inform design decisions.

- Limit Equilibrium Methods: These methods analyze the forces acting on a potential failure surface, calculating the factor of safety (FOS). An FOS less than 1 indicates an unstable slope. Various limit equilibrium methods exist, each with its own assumptions and complexities.

- Numerical Modeling: Advanced techniques like finite element analysis (FEA) and distinct element modeling (DEM) provide more detailed analyses, considering the complex geometry and behavior of rock masses.

Software like Rocscience Slide, RS2, and FLAC are commonly used to perform these analyses. The selection of the appropriate method depends on the complexity of the problem and the available data. Rockfall analysis is also crucial for assessing the risk of rockfalls from slopes.

Practical Applications of the Big Rig ROCK Report 3.12

The principles outlined in the Big Rig ROCK Report 3.12 find widespread applications across various industries:

Mining Applications

The report significantly impacts safe and efficient mining practices. It informs decisions related to:

- Open-Pit Slope Design: Optimizing slope angles to maintain stability and minimize the risk of slope failures.

- Underground Mine Development: Designing stable underground openings and choosing appropriate ground support measures.

- Ground Support Selection: Selecting suitable support systems (rock bolts, shotcrete, etc.) based on the rock mass characteristics.

Civil Engineering Applications

The report's principles are essential for various civil engineering projects:

- Dam Construction: Assessing the stability of dam foundations and abutments.

- Tunnel Excavation: Designing stable tunnels and selecting appropriate support measures.

- Foundation Design: Determining the appropriate foundation design for structures built on rock.

Environmental Considerations

Rock mechanics plays a crucial role in environmental projects. The report contributes to sustainable practices by:

- Minimizing Environmental Impact: Properly assessing rock mass stability helps reduce the risk of landslides and other environmental hazards.

- Optimizing Resource Use: Understanding rock mass characteristics enables efficient resource extraction while minimizing waste.

Conclusion

The Big Rig ROCK Report 3.12 serves as an invaluable resource for understanding and applying rock mechanics principles in various engineering and mining projects. By mastering the concepts of rock mass classification, strength and deformability, joint characteristics, and slope stability analysis, professionals can significantly improve the safety and efficiency of their work. This guide only scratches the surface; a deep dive into the Big Rig ROCK Report 3.12 and further exploration of rock mechanics training and geotechnical engineering resources are strongly recommended for a comprehensive understanding. Embrace the knowledge within the Big Rig ROCK Report 3.12 and elevate your proficiency in rock mass characterization techniques.

Featured Posts

-

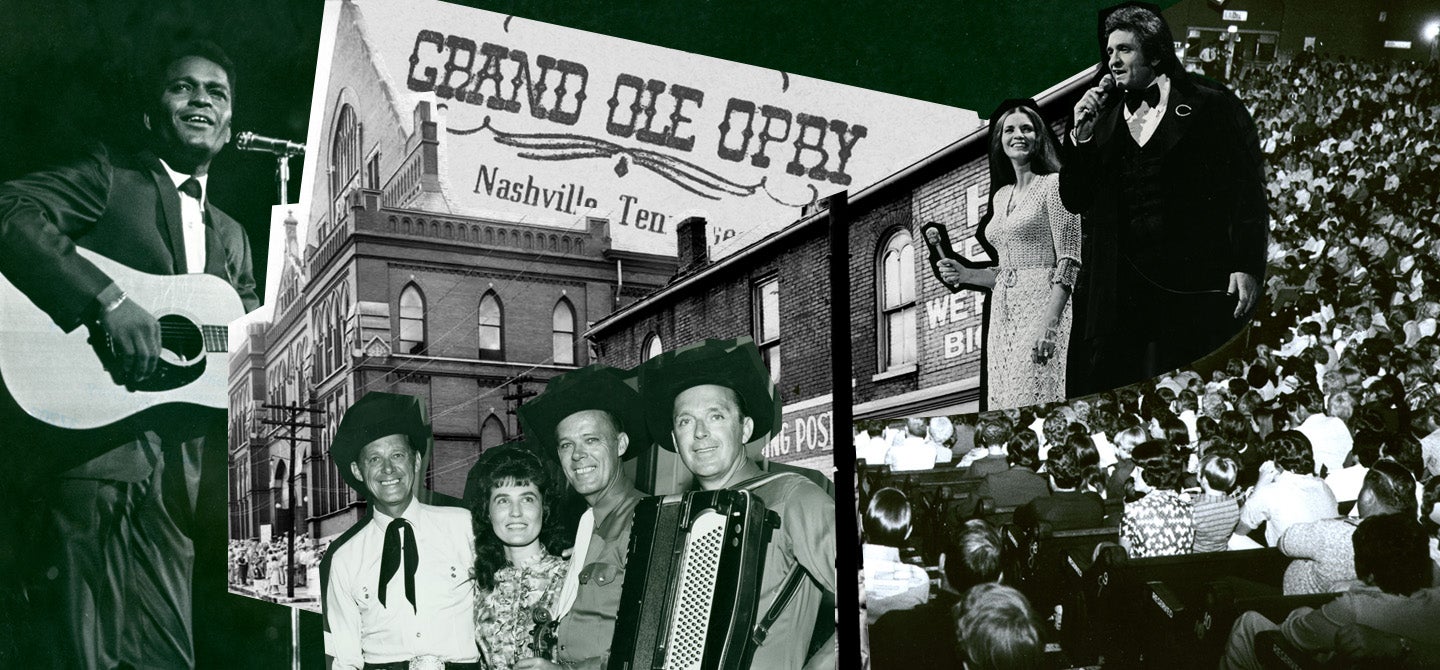

Grand Ole Oprys Historic London Show Royal Albert Hall Broadcast Details

May 23, 2025

Grand Ole Oprys Historic London Show Royal Albert Hall Broadcast Details

May 23, 2025 -

Grand Ole Opry Goes Global First International Broadcast From Londons Royal Albert Hall

May 23, 2025

Grand Ole Opry Goes Global First International Broadcast From Londons Royal Albert Hall

May 23, 2025 -

Hulus October Departures A Comprehensive List Of Movies

May 23, 2025

Hulus October Departures A Comprehensive List Of Movies

May 23, 2025 -

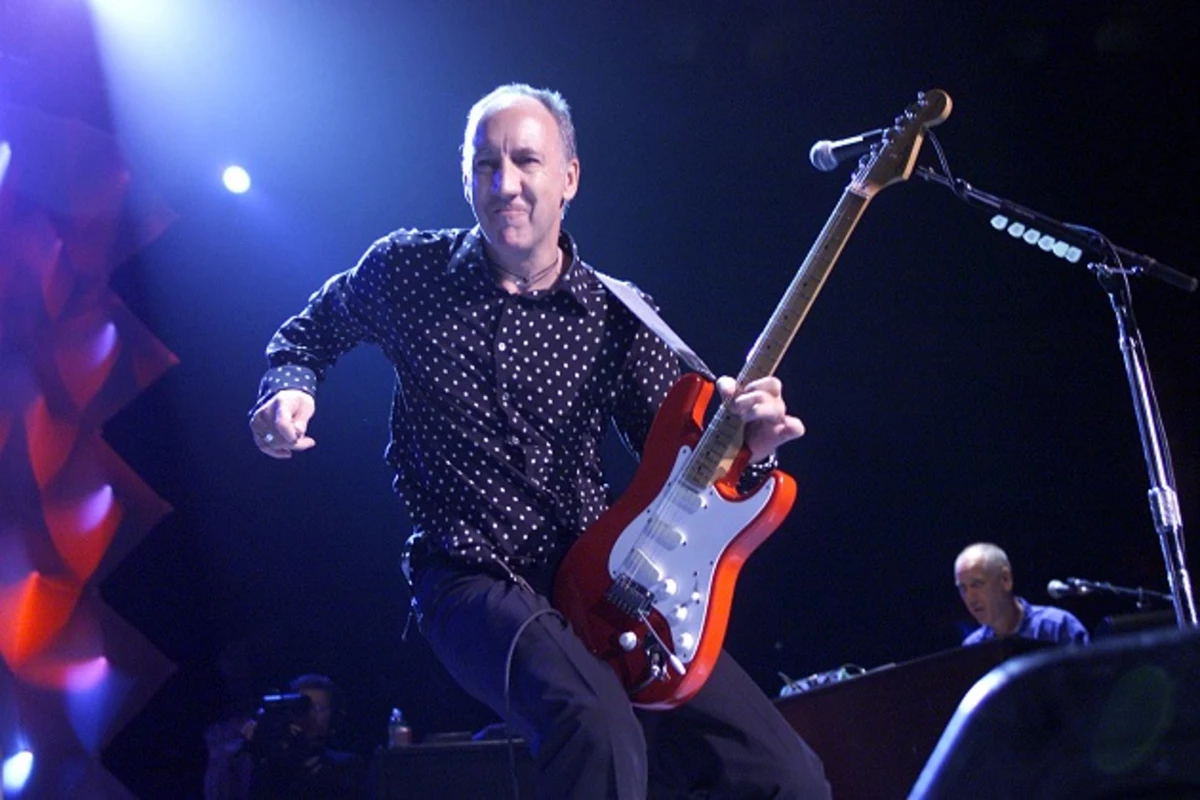

The 10 Greatest Pete Townshend Tracks Ever Recorded

May 23, 2025

The 10 Greatest Pete Townshend Tracks Ever Recorded

May 23, 2025 -

El Cansancio Fifa Como Afecta A La Real Sociedad

May 23, 2025

El Cansancio Fifa Como Afecta A La Real Sociedad

May 23, 2025

Latest Posts

-

Ooredoo And Qtspbf A Winning Partnership Continues

May 23, 2025

Ooredoo And Qtspbf A Winning Partnership Continues

May 23, 2025 -

Ooredoo Qatar And Qtspbf Extend Successful Partnership

May 23, 2025

Ooredoo Qatar And Qtspbf Extend Successful Partnership

May 23, 2025 -

A Weekend Of Events Fashion Heritage Ballet And Puns Included

May 23, 2025

A Weekend Of Events Fashion Heritage Ballet And Puns Included

May 23, 2025 -

Weekend Events Featuring Fashion Heritage Ballet And More

May 23, 2025

Weekend Events Featuring Fashion Heritage Ballet And More

May 23, 2025 -

Fashion Heritage And Ballet Weekend Events Not To Miss

May 23, 2025

Fashion Heritage And Ballet Weekend Events Not To Miss

May 23, 2025