US Army's Right-to-Repair Policy: Challenges And Opportunities

Table of Contents

Challenges of Implementing a Right-to-Repair Policy in the US Army

Implementing a comprehensive right-to-repair policy within the US Army presents several significant hurdles. These challenges need careful consideration and proactive solutions to ensure the success of such an initiative.

Supply Chain and Logistics

Efficient repair hinges on seamless supply chain management. However, the military faces unique logistical challenges:

- Proprietary Parts: Obtaining proprietary parts from original equipment manufacturers (OEMs) can be expensive, time-consuming, and subject to unpredictable delays. These OEMs often hold monopolies on specific components, limiting the Army's options.

- Remote Locations: Transporting repair components to remote bases and operational environments in a timely manner presents a significant logistical hurdle. This involves overcoming geographical barriers, security considerations, and the overall complexity of moving sensitive materials.

- Supply Chain Disruptions: Global supply chain disruptions, as witnessed recently, can severely impact repair times, leaving critical equipment out of service for extended periods. Building resilience into the supply chain is essential.

Maintaining Security and Confidentiality

Repairing complex military equipment requires stringent security measures to prevent unauthorized access and potential breaches:

- Data Protection: Modern military equipment often contains sensitive data, including operational plans, communication codes, and positioning information. Unauthorized access could have catastrophic consequences.

- Reverse Engineering: Repair procedures must be carefully designed to prevent reverse engineering of sensitive military technologies, which could compromise national security and intellectual property.

- Secure Protocols: Implementing robust access controls and secure repair protocols are crucial to maintain the confidentiality and integrity of sensitive military equipment and data.

Training and Skill Development

A successful right-to-repair program demands a highly skilled workforce:

- Standardized Procedures: Developing clear and standardized repair procedures is essential to ensure consistency and effectiveness across different units and locations.

- Advanced Training: Investing in advanced training technologies, such as virtual reality simulations, can significantly enhance the skills and knowledge of maintenance personnel.

- Continuous Professional Development: Continuous professional development programs are necessary to keep personnel updated on the latest technologies and repair techniques.

Cost-Effectiveness Analysis

A comprehensive cost-benefit analysis is vital before implementing a right-to-repair policy:

- Lifecycle Cost: Carefully comparing the lifecycle cost of repairing equipment versus replacing it is crucial for determining long-term cost-effectiveness.

- Return on Investment (ROI): Assessing the return on investment (ROI) of a right-to-repair program, considering initial investment in training, tools, and infrastructure, is necessary to justify the program's budget allocation.

- Repair Strategies: Evaluating the cost-effectiveness of different repair strategies, such as in-house repairs versus outsourcing, is critical for optimizing resource allocation.

Opportunities Presented by a Strong Right-to-Repair Policy

Despite the challenges, a robust right-to-repair policy offers substantial advantages for the US Army:

Enhanced Operational Readiness

Improved repair capabilities translate directly into enhanced operational readiness:

- Faster Repair Times: Reduced repair times mean quicker equipment restoration, minimizing downtime and ensuring greater availability.

- Reduced Reliance on Contractors: Decreased reliance on external contractors leads to faster response times and greater control over the repair process.

- Improved Equipment Uptime: Increased equipment uptime enhances mission success rates and improves overall operational efficiency.

- Operational Flexibility: Greater flexibility in deploying and maintaining equipment in diverse environments is achieved.

Cost Savings and Budgetary Efficiency

The potential for cost savings is significant:

- Reduced Repair Costs: In-house repairs are typically less expensive than outsourcing to OEMs, resulting in substantial cost reductions.

- Lower Disposal Fees: Extending the lifespan of equipment reduces the number of units needing disposal, lowering associated fees.

- Improved Resource Allocation: Cost savings can be redirected to other essential military programs and initiatives.

- In-house Capabilities: Developing in-house repair capabilities creates a sustainable and cost-effective maintenance model.

Fostering Technological Independence and Innovation

A right-to-repair policy strengthens national security:

- Domestic Manufacturing: It stimulates domestic manufacturing and job creation, reducing dependence on foreign suppliers.

- Innovation in Repair: It encourages innovation in repair technologies and techniques, leading to more efficient and effective maintenance practices.

- Supply Chain Resilience: It reduces vulnerabilities in the military supply chain, ensuring greater resilience in times of crisis.

Environmental Sustainability

Repairing equipment is environmentally responsible:

- Reduced E-waste: Repairing equipment significantly reduces the generation of electronic waste, minimizing environmental impact.

- Resource Conservation: Extending the lifespan of equipment conserves valuable resources and reduces the need for new manufacturing.

- Circular Economy: It promotes circular economy principles within the military, contributing to a more sustainable approach to resource management.

Conclusion

The US Army's right-to-repair policy presents a complex but critical challenge. While concerns regarding security, training, and supply chain logistics must be addressed proactively, the potential benefits—significant cost savings, enhanced operational readiness, technological independence, and environmental sustainability—are undeniable. The future of the US Army's operational readiness depends on a well-considered and implemented right-to-repair policy. Continue the conversation and explore the potential of a comprehensive right-to-repair program for improved military capabilities.

Featured Posts

-

Kanye West And Bianca Censori Spain Dinner Date After Breakup Claims

May 18, 2025

Kanye West And Bianca Censori Spain Dinner Date After Breakup Claims

May 18, 2025 -

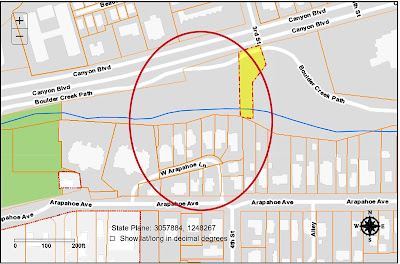

Boulder Countys Switzerland Trail A Mining History

May 18, 2025

Boulder Countys Switzerland Trail A Mining History

May 18, 2025 -

Arsenals Transfer Target Stuttgart Midfielder

May 18, 2025

Arsenals Transfer Target Stuttgart Midfielder

May 18, 2025 -

Addressing Bostons Bullpen Uncertainty Analyzing The Red Sox Cardinals Trade

May 18, 2025

Addressing Bostons Bullpen Uncertainty Analyzing The Red Sox Cardinals Trade

May 18, 2025 -

Kalorama 2025 Festival Pet Shop Boys Fka Twigs Jorja Smith And Father John Misty Announced

May 18, 2025

Kalorama 2025 Festival Pet Shop Boys Fka Twigs Jorja Smith And Father John Misty Announced

May 18, 2025

Latest Posts

-

You Toon Caption Contest Winner Announced Booing Bears Takes The Prize

May 18, 2025

You Toon Caption Contest Winner Announced Booing Bears Takes The Prize

May 18, 2025 -

The Swim With Mike Program A Lifeline For The Trojan Community

May 18, 2025

The Swim With Mike Program A Lifeline For The Trojan Community

May 18, 2025 -

Brave Suffolk Teen Rescues Child From Drowning

May 18, 2025

Brave Suffolk Teen Rescues Child From Drowning

May 18, 2025 -

Stephen Millers Potential Appointment As National Security Advisor Reports Analyzed

May 18, 2025

Stephen Millers Potential Appointment As National Security Advisor Reports Analyzed

May 18, 2025 -

Analyzing The Economic Influence Of Large Scale Rave Concerts

May 18, 2025

Analyzing The Economic Influence Of Large Scale Rave Concerts

May 18, 2025