Are American Factory Jobs Coming Back? A Realistic Assessment

Table of Contents

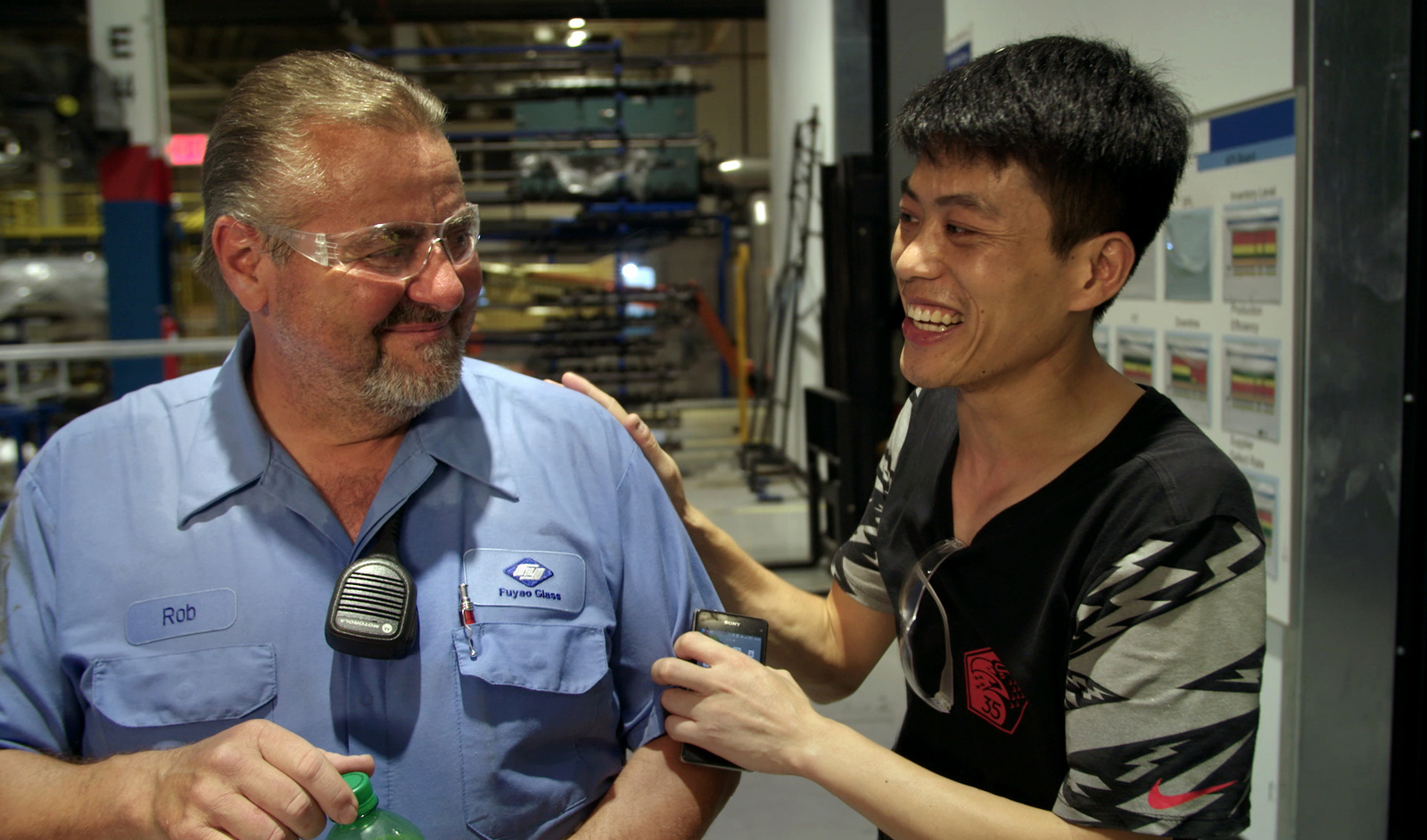

The decline of American manufacturing began decades ago, accelerated by the rise of cheaper overseas labor and the increasing efficiency of automation. This resulted in significant job losses and economic shifts across the country. This article will explore the factors contributing to both the decline and the potential for a comeback, providing a balanced view of the future of American factory jobs.

The Reshoring Trend: A Closer Look

The term "reshoring" describes the return of manufacturing operations from overseas to the United States. This trend, while promising for American factory jobs, is far from a guaranteed solution to the problem.

Factors Driving Reshoring:

- Rising Labor Costs Abroad: Wage increases in countries like China and Vietnam are making manufacturing in those regions less cost-effective than it once was. This is a significant factor driving companies to reconsider their global production strategies.

- Supply Chain Disruptions: Events such as the COVID-19 pandemic exposed the vulnerabilities of overly reliant global supply chains. The resulting disruptions highlighted the benefits of domestic production for resilience and reduced lead times.

- Government Incentives and Policies: The US government has implemented various policies aimed at encouraging reshoring, including tax breaks, tariffs on imported goods, and investment in infrastructure supporting domestic manufacturing. These incentives aim to make domestic production more attractive.

- Growing Consumer Demand for "Made in America": A rising consumer preference for products manufactured domestically is creating market demand, pushing companies to meet this growing need and boost American factory jobs.

Limitations of Reshoring:

- Automation's Impact on Job Creation: While reshoring brings manufacturing back to the US, automation often reduces the number of jobs created compared to traditional manufacturing processes. This raises concerns about job displacement.

- The Skills Gap: The resurgence of American manufacturing requires a skilled workforce. A significant skills gap exists, needing investments in retraining and education programs to prepare the workforce for advanced manufacturing roles.

- Competition from Highly Efficient Foreign Manufacturers: Even with reshoring, American manufacturers still face stiff competition from highly efficient and technologically advanced manufacturers in other countries.

- High Establishment Costs: Establishing and maintaining manufacturing facilities in the US is significantly more expensive than in many other parts of the world, posing a challenge to the profitability of reshoring initiatives.

Automation and the Future of Manufacturing Jobs

Automation is reshaping the landscape of American factory jobs. While it contributes to decreased labor costs and increased efficiency, it also raises concerns about job displacement.

The Role of Automation:

- Robots and AI: The increasing integration of robots and artificial intelligence in factories is transforming production processes, automating tasks previously performed by human workers.

- Shift in Job Types: Automation is shifting the demand for labor from manual labor towards skilled technical roles such as robotics engineers, software developers, and maintenance technicians.

- Job Displacement vs. Creation: While automation can lead to job displacement in certain sectors, it also creates new opportunities in related fields, requiring significant investment in workforce retraining and upskilling initiatives.

Upskilling and Retraining Initiatives:

- Government and Private Sector Efforts: Various government programs and private sector initiatives are investing in training programs to equip workers with the skills needed for advanced manufacturing jobs. These include apprenticeships and specialized training programs.

- STEM Education: Strengthening STEM (Science, Technology, Engineering, and Mathematics) education is crucial to develop a future workforce capable of operating and maintaining advanced manufacturing equipment.

- Effectiveness of Retraining Programs: The effectiveness of current retraining programs varies greatly, highlighting the need for continuous evaluation and improvement to ensure they adequately address the evolving needs of the American manufacturing sector.

Government Policies and Their Impact

Government policies play a pivotal role in shaping the future of American factory jobs. These policies, ranging from trade regulations to infrastructure investments, significantly influence the attractiveness of domestic manufacturing.

Trade Policies and Tariffs:

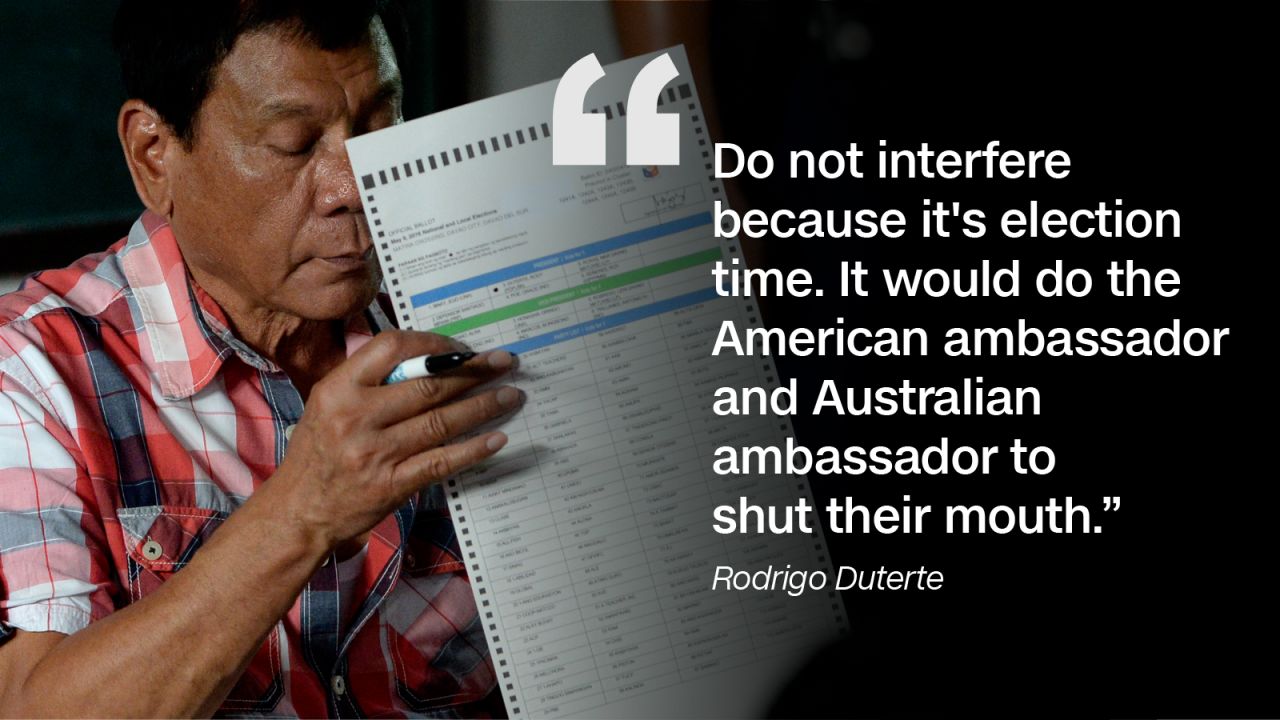

- Impact on Manufacturing Jobs: Trade policies, including tariffs, aim to protect domestic industries from foreign competition, potentially leading to the return of some manufacturing jobs.

- Potential Downsides of Protectionism: Protectionist measures can lead to higher consumer prices, reduced choice, and potential retaliatory tariffs from other countries.

- Impact on Consumer Prices: Tariffs can increase the price of imported goods, affecting consumer spending and potentially impacting the overall economy.

Infrastructure Investment:

- Supporting Domestic Manufacturing: Investing in modern infrastructure, including transportation networks and energy grids, is essential for supporting efficient and cost-effective domestic manufacturing.

- Reducing Transportation Costs: Improved infrastructure reduces transportation costs, making domestic production more competitive.

Tax Incentives and Subsidies:

- Attracting Manufacturers: Tax incentives and subsidies can attract manufacturing companies to establish or expand operations in the US.

- Unintended Consequences: These incentives can sometimes lead to unintended consequences, such as the relocation of manufacturing operations within the US, rather than from overseas, or the potential for misuse of funds.

Conclusion

The question of whether American factory jobs are returning is complex, with no simple answer. While reshoring initiatives, driven by rising overseas labor costs, supply chain disruptions, and government policies, show some promise, the impact of automation and the need for a skilled workforce cannot be overlooked. The future of American manufacturing hinges on a strategic approach that addresses both reshoring efforts and the challenges posed by automation. A balanced perspective is crucial, recognizing both opportunities and limitations. Understanding the intricacies of the return of American factory jobs is crucial. Stay informed and advocate for policies that support the growth of skilled manufacturing roles in the US, contributing to a robust and sustainable American manufacturing sector and securing the future of American manufacturing jobs and US factory jobs.

Featured Posts

-

Lufthansa Co Pilot Fainting Incident Flight Continues Without Pilot For 10 Minutes

May 20, 2025

Lufthansa Co Pilot Fainting Incident Flight Continues Without Pilot For 10 Minutes

May 20, 2025 -

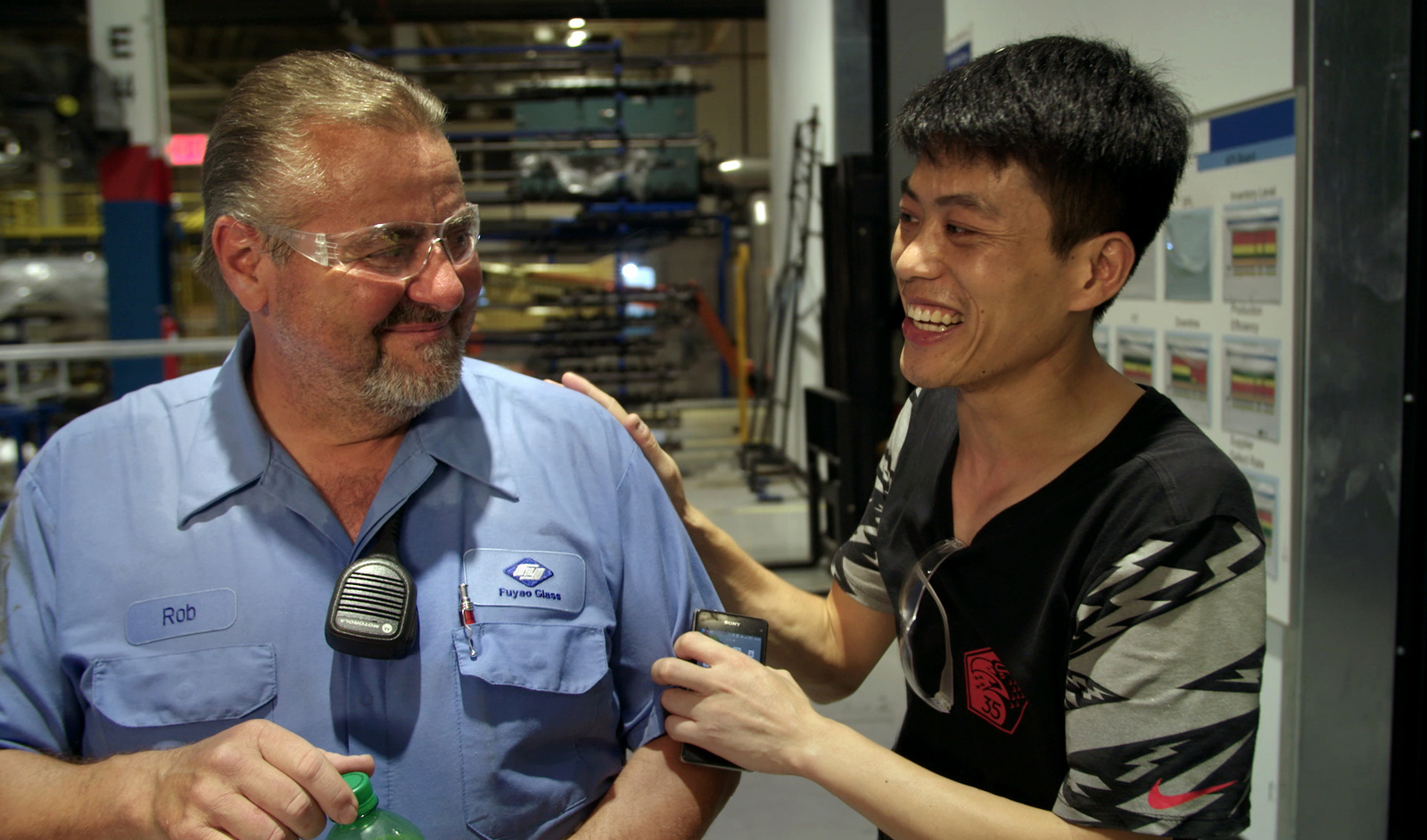

From Ragbrai To Daily Rides Scott Savilles Passion For Cycling

May 20, 2025

From Ragbrai To Daily Rides Scott Savilles Passion For Cycling

May 20, 2025 -

Navy Admirals Bribery Case Exposes Systemic Cultural Problems

May 20, 2025

Navy Admirals Bribery Case Exposes Systemic Cultural Problems

May 20, 2025 -

Michael Schumacher Une Petite Fille Pour Le Champion

May 20, 2025

Michael Schumacher Une Petite Fille Pour Le Champion

May 20, 2025 -

Michael Schumacher Grand Pere Pour La Premiere Fois D Une Petite Fille

May 20, 2025

Michael Schumacher Grand Pere Pour La Premiere Fois D Une Petite Fille

May 20, 2025

Latest Posts

-

Federal Leaders Saskatchewan Visit Analysis Of Controversial Remarks

May 21, 2025

Federal Leaders Saskatchewan Visit Analysis Of Controversial Remarks

May 21, 2025 -

Financial Times Bps Ceo Plans For Significant Valuation Increase No Us Market Shift

May 21, 2025

Financial Times Bps Ceo Plans For Significant Valuation Increase No Us Market Shift

May 21, 2025 -

Saskatchewan Political Panel Federal Leaders Visit Sparks Controversy

May 21, 2025

Saskatchewan Political Panel Federal Leaders Visit Sparks Controversy

May 21, 2025 -

Bp Ceo Targets Valuation Doubling Remains Committed To Current Stock Exchange Listing

May 21, 2025

Bp Ceo Targets Valuation Doubling Remains Committed To Current Stock Exchange Listing

May 21, 2025 -

Bp Chief Aims To Double Company Valuation No Us Listing Planned Reports Ft

May 21, 2025

Bp Chief Aims To Double Company Valuation No Us Listing Planned Reports Ft

May 21, 2025