Automating Workboats: The TBS Safety And Nebofleet Collaboration

Table of Contents

Enhanced Safety through Automation

Automating critical functions on workboats significantly enhances safety by mitigating risks inherent in human-operated systems. This collaboration focuses on two key aspects: reducing human error and improving crew wellbeing.

Reducing Human Error

Automation minimizes human error, a significant contributor to accidents at sea. The integration of TBS Safety systems with the Nebofleet platform provides real-time monitoring and automated alerts, leading to:

- Reduced risk of collisions: Automated collision avoidance systems, integrated with Nebofleet's data visualization, provide early warnings and navigational assistance, significantly reducing the risk of accidents.

- Improved navigation in challenging conditions: Automated systems enhance situational awareness in adverse weather or low visibility, guiding vessels safely through difficult waters.

- Automated emergency response systems: Real-time monitoring and automated alerts enable faster response times in emergency situations, potentially saving lives and minimizing damage.

The TBS Safety systems constantly monitor critical parameters. If an anomaly is detected—for example, a sudden change in course or speed—an immediate alert is sent to the crew and shore-based teams via the Nebofleet platform. This proactive approach minimizes the likelihood of accidents caused by human oversight or fatigue.

Improved Crew Wellbeing

Automating repetitive tasks frees up crew members, reducing fatigue and improving overall safety. This leads to:

- Increased focus on critical tasks: By automating routine monitoring and data logging, crews can focus on higher-level tasks requiring human judgment and expertise.

- Reduced workload: Automation significantly reduces the physical and mental strain on the crew, leading to improved alertness and reduced risk of error.

- Improved crew morale: A less stressful and more efficient work environment boosts crew morale and job satisfaction, contributing to a safer and more productive operation.

For instance, the automated fuel monitoring and engine performance tracking within Nebofleet significantly reduces the time spent on manual checks, allowing the crew to focus on preventative maintenance and other critical tasks.

Optimizing Workboat Efficiency with Nebofleet's Integration

Nebofleet's integration provides a powerful platform for optimizing workboat efficiency through real-time data and streamlined communication.

Real-time Data & Monitoring

Nebofleet provides a centralized platform for real-time data visualization, enabling proactive maintenance and optimized operations. Key benefits include:

- Fuel consumption monitoring: Real-time fuel consumption data allows for efficient route planning and identification of potential fuel leaks or inefficiencies.

- Engine performance tracking: Continuous monitoring of engine performance identifies potential issues before they escalate into major problems, minimizing downtime and maintenance costs.

- Predictive maintenance scheduling: Data analysis enables predictive maintenance scheduling, reducing unexpected breakdowns and maximizing operational uptime.

The Nebofleet user interface presents this data in an intuitive and easily digestible format, providing actionable insights for improved decision-making. Users can visualize data through customizable dashboards, generating reports for performance analysis and optimization.

Streamlined Communication & Collaboration

Enhanced communication capabilities within Nebofleet improve coordination between vessels and shore teams, resulting in:

- Improved communication between crew members: Real-time messaging and data sharing within the platform enhance communication and coordination among crew members.

- Real-time updates on vessel status: Shore-based teams receive real-time updates on vessel location, status, and performance, allowing for proactive management and support.

- Efficient dispatching of resources: Nebofleet facilitates efficient dispatching of resources, such as maintenance crews or emergency response teams, based on real-time data and location information.

This improved communication streamlines operations, reducing delays and improving overall efficiency. For example, if a vessel experiences a mechanical issue, the crew can instantly communicate the problem to shore teams, triggering a swift response and minimizing downtime.

The Future of Automating Workboats: TBS Safety and Nebofleet's Vision

The collaboration between TBS Safety and Nebofleet envisions a future where advanced technologies drive even greater improvements in workboat automation.

Advanced Technologies

Future plans include incorporating AI, machine learning, and other advanced technologies:

- Potential for autonomous navigation: Integration of AI-powered autonomous navigation systems could significantly enhance safety and efficiency in the future.

- Predictive maintenance through AI: AI-driven predictive maintenance will optimize maintenance schedules, minimizing downtime and maximizing the lifespan of equipment.

- Enhanced safety features driven by machine learning: Machine learning algorithms can analyze vast amounts of data to identify patterns and predict potential safety hazards, proactively mitigating risks.

These advancements will further enhance safety, efficiency, and sustainability in workboat operations.

Sustainability & Environmental Impact

Automation contributes to more sustainable and environmentally friendly workboat operations by:

- Optimized fuel consumption: Data-driven insights from Nebofleet lead to optimized fuel consumption, reducing both operational costs and environmental impact.

- Reduced emissions: Improved engine performance and reduced idling time contribute to lower greenhouse gas emissions.

- Improved waste management: Automated systems can optimize waste management processes, minimizing environmental pollution.

By reducing fuel consumption and emissions, automated workboats contribute significantly to a more sustainable maritime industry.

Conclusion

This collaboration between TBS Safety and Nebofleet represents a significant leap forward in automating workboats, enhancing safety, efficiency, and sustainability in the maritime industry. The integrated platform offers real-time monitoring, streamlined communication, and predictive maintenance capabilities, leading to significant improvements in workboat operations. This partnership showcases a commitment to innovation and a vision for a safer, more efficient, and environmentally conscious future for workboats.

Learn more about how automating workboats with TBS Safety and Nebofleet can benefit your operations. Contact us today to explore the possibilities and take your workboat efficiency to the next level.

Featured Posts

-

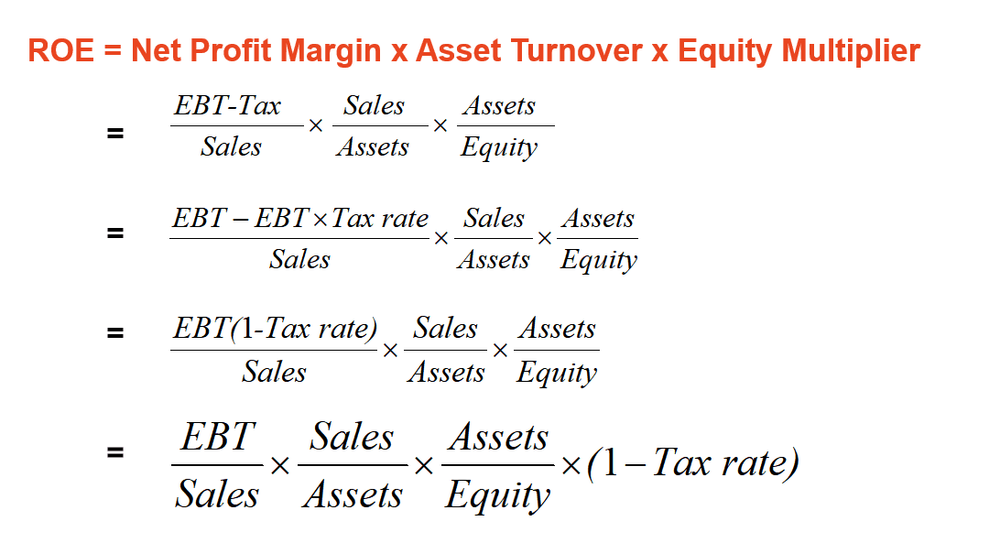

Should Investors Worry About Current Stock Market Valuations Bof As Take

May 02, 2025

Should Investors Worry About Current Stock Market Valuations Bof As Take

May 02, 2025 -

11 Point Masterclass Duponts Key Role In Frances Victory Against Italy

May 02, 2025

11 Point Masterclass Duponts Key Role In Frances Victory Against Italy

May 02, 2025 -

Is The Eco Flow Wave 3 The Best Portable Climate Control Solution A Review

May 02, 2025

Is The Eco Flow Wave 3 The Best Portable Climate Control Solution A Review

May 02, 2025 -

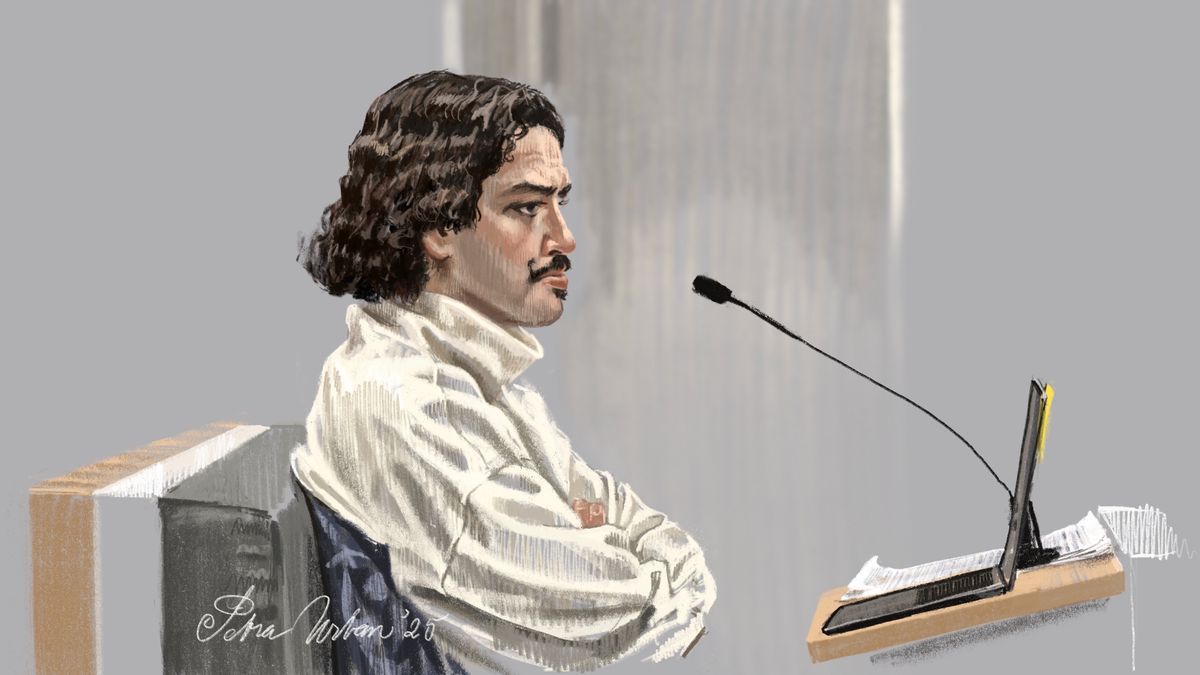

Levenslang Voor Fouad L De Argumenten Achter De Straf In De Erasmusschutterzaak

May 02, 2025

Levenslang Voor Fouad L De Argumenten Achter De Straf In De Erasmusschutterzaak

May 02, 2025 -

Tonga Dashes Sis Olympic Hopes

May 02, 2025

Tonga Dashes Sis Olympic Hopes

May 02, 2025

Latest Posts

-

Fortnites Negan Jeffrey Dean Morgan Discusses His Characters Appearance

May 02, 2025

Fortnites Negan Jeffrey Dean Morgan Discusses His Characters Appearance

May 02, 2025 -

Fortnites Refund Policy Update Implications For Cosmetic Items

May 02, 2025

Fortnites Refund Policy Update Implications For Cosmetic Items

May 02, 2025 -

Fortnite Rare Skins You Might Never See Again

May 02, 2025

Fortnite Rare Skins You Might Never See Again

May 02, 2025 -

Jeffrey Dean Morgan On Negans Fortnite Role An Interview

May 02, 2025

Jeffrey Dean Morgan On Negans Fortnite Role An Interview

May 02, 2025 -

Fortnite Issues Refunds A Sign Of Cosmetic Policy Shifts

May 02, 2025

Fortnite Issues Refunds A Sign Of Cosmetic Policy Shifts

May 02, 2025