Dysprosium's Critical Role In Electric Vehicle Motors And The Looming Supply Chain Crisis

Table of Contents

Dysprosium's Essential Role in EV Motor Magnets

Dysprosium is a key component in neodymium magnets, which are essential for the high-torque, high-efficiency performance of electric vehicle motors. These magnets are significantly stronger and more compact than traditional alternatives, allowing for substantial improvements in EV design and functionality. Without dysprosium, the powerful and efficient motors needed for optimal EV performance simply wouldn't be possible.

- Enhances magnetic strength and thermal stability: Dysprosium's addition significantly improves the magnet's resistance to demagnetization at high temperatures, crucial for maintaining motor performance under demanding operating conditions. This is especially important for EVs operating in hot climates or under heavy load.

- Allows for smaller, lighter, and more powerful motors: The superior magnetic properties of dysprosium-enhanced neodymium magnets allow for the design of smaller and lighter motors without sacrificing power. This contributes to improved vehicle efficiency and range.

- Crucial for achieving optimal range and performance in EVs: The efficiency gains provided by these powerful magnets directly translate to extended driving range and enhanced performance for electric vehicles. This is a key selling point for consumers.

- Used in both permanent magnet synchronous motors (PMSM) and brushless DC motors (BLDC): These motor types are dominant in the EV industry, making dysprosium's role even more critical. The vast majority of EVs rely on these motor designs.

The Geographic Concentration of Dysprosium and Supply Chain Vulnerabilities

A significant portion of the world's dysprosium supply is concentrated in a few countries, primarily China. This geographic concentration creates significant vulnerabilities in the supply chain, making the EV industry highly dependent on a single source. This reliance presents considerable risks.

- China's dominance in mining, refining, and processing of dysprosium: China controls a substantial portion of the global dysprosium market, from extraction to processing, creating a potential chokepoint for the entire EV sector.

- Geopolitical risks associated with reliance on a single source: Political tensions, trade disputes, or unexpected events in China could significantly disrupt the supply of dysprosium, severely impacting EV production.

- Vulnerability to trade disputes, political instability, and natural disasters: Any disruption to Chinese mining or processing operations, whether due to political instability or natural disasters, could have cascading effects throughout the global EV industry.

- Potential for price volatility and supply disruptions: The limited supply and concentrated nature of dysprosium production make it prone to price fluctuations, potentially increasing the cost of manufacturing EVs.

The Impact of Dysprosium Shortages on EV Production

Dysprosium shortages can lead to delays and increased costs in EV manufacturing, hindering the global adoption of electric vehicles. The consequences of a dysprosium shortage are far-reaching.

- Increased production costs for EV manufacturers: A scarcity of dysprosium will inevitably drive up prices, making EVs more expensive to produce and impacting consumer affordability.

- Potential delays in EV production timelines: Manufacturers may be forced to halt or slow production due to a lack of essential materials, leading to delays in deliveries and unmet demand.

- Limited availability of EVs in the market: The shortage could restrict the number of EVs available for sale, slowing the transition to cleaner transportation options.

- Negative impact on the transition to sustainable transportation: A dysprosium supply crisis could significantly hinder the global effort to reduce carbon emissions and mitigate climate change.

Strategies to Mitigate Dysprosium Supply Chain Risks

Addressing the dysprosium supply chain crisis requires a multi-pronged approach involving diversification of sources, technological innovation, and responsible mining practices. A collaborative global effort is needed to ensure a sustainable future for the EV industry.

- Exploration and development of new dysprosium deposits globally: Investing in geological surveys and exploration efforts in various countries to identify and develop new dysprosium sources is paramount.

- Investment in recycling and reuse of dysprosium from end-of-life EVs: Developing efficient and cost-effective recycling technologies to recover dysprosium from discarded batteries is crucial for reducing reliance on primary mining.

- Research and development of alternative magnet materials with reduced reliance on rare earths: Scientists and engineers must actively explore and develop alternative magnet materials that minimize or eliminate the need for rare earth elements like dysprosium.

- Implementing sustainable mining practices to minimize environmental impact: Responsible mining practices are essential to ensure the long-term viability of dysprosium production while mitigating environmental damage.

- Strengthening international cooperation to ensure stable supply chains: Collaborative efforts among governments, industries, and research institutions are critical for developing robust and secure dysprosium supply chains.

Conclusion

Dysprosium's critical role in electric vehicle motor performance cannot be overstated. However, the current reliance on limited sources creates a significant supply chain vulnerability that threatens the future of the EV industry. Addressing this challenge requires a proactive and multifaceted approach encompassing responsible sourcing, technological advancements, and collaborative international efforts. Ignoring the looming dysprosium supply chain crisis risks jeopardizing the global transition to sustainable electric transportation. We must invest in research, develop alternative technologies, and diversify sources to ensure a secure and sustainable supply of dysprosium for the electric vehicle revolution. Learn more about the future of dysprosium and its impact on electric vehicle motor technology and how to mitigate the risks associated with dysprosium shortages.

Featured Posts

-

Luxury Car Sales In China Why Bmw And Porsche Are Facing Headwinds

Apr 29, 2025

Luxury Car Sales In China Why Bmw And Porsche Are Facing Headwinds

Apr 29, 2025 -

The Unexpected Rise Of Macario Martinez From Street Sweeper To National Fame

Apr 29, 2025

The Unexpected Rise Of Macario Martinez From Street Sweeper To National Fame

Apr 29, 2025 -

Missing Person British Paralympian Last Seen In Las Vegas Over A Week Ago

Apr 29, 2025

Missing Person British Paralympian Last Seen In Las Vegas Over A Week Ago

Apr 29, 2025 -

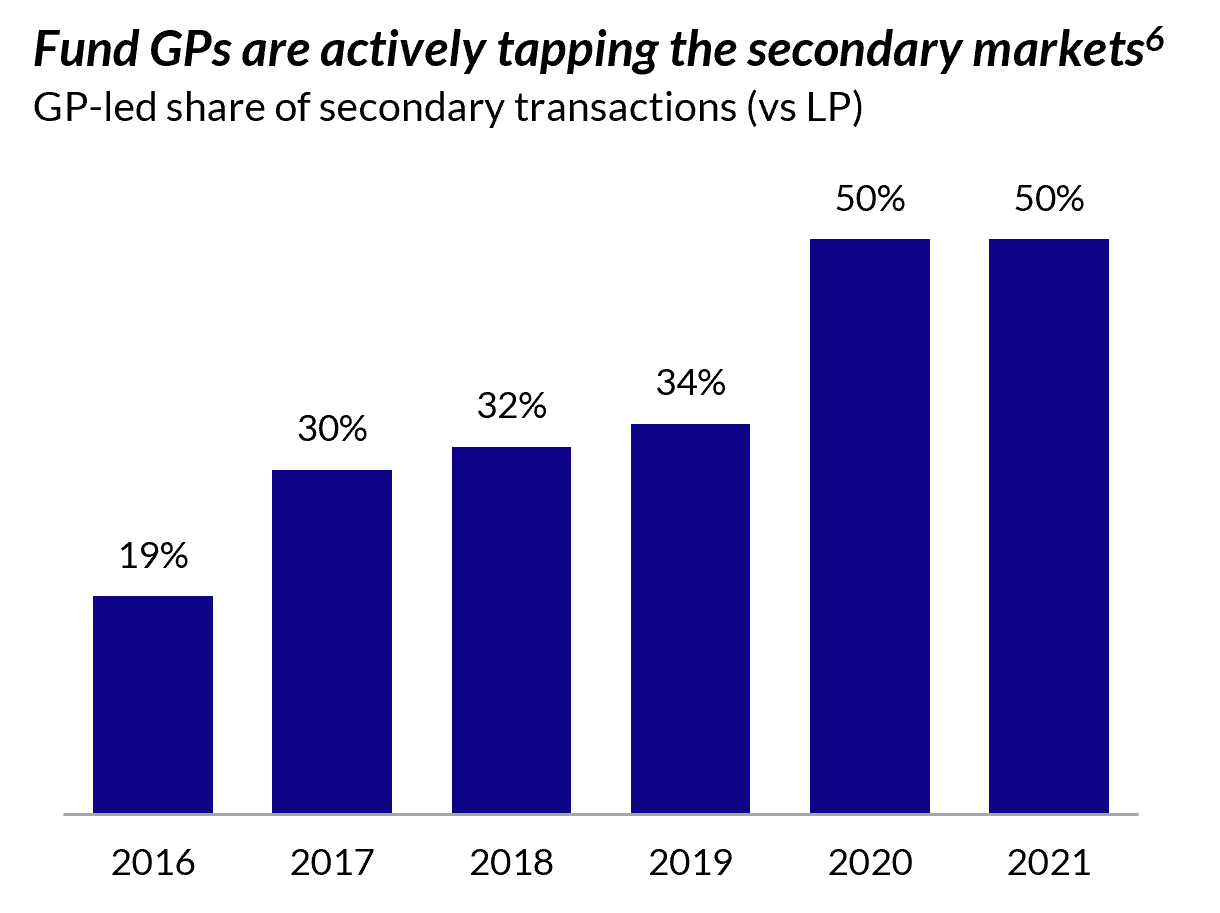

Why The Venture Capital Secondary Market Is Booming

Apr 29, 2025

Why The Venture Capital Secondary Market Is Booming

Apr 29, 2025 -

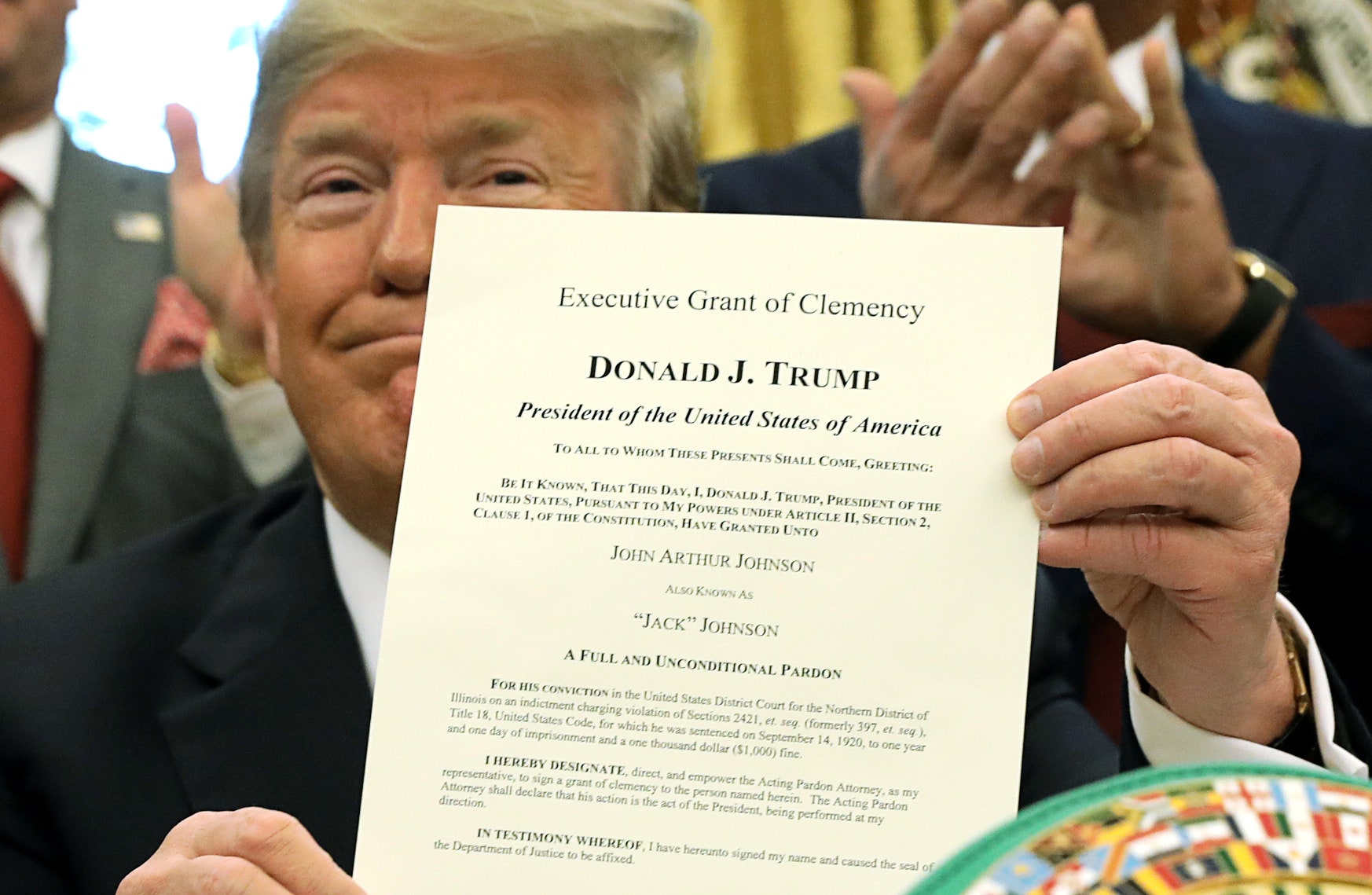

Full Pardon For Rose Trumps Decision And Its Fallout

Apr 29, 2025

Full Pardon For Rose Trumps Decision And Its Fallout

Apr 29, 2025

Latest Posts

-

Geary County Sheriffs Office Bookings April 24 28 Photo Gallery

Apr 29, 2025

Geary County Sheriffs Office Bookings April 24 28 Photo Gallery

Apr 29, 2025 -

Geary County Mugshots April 24 28 Bookings

Apr 29, 2025

Geary County Mugshots April 24 28 Bookings

Apr 29, 2025 -

Capital Summertime Ball 2025 Wembley Stadium Dates Ticket Information And Lineup

Apr 29, 2025

Capital Summertime Ball 2025 Wembley Stadium Dates Ticket Information And Lineup

Apr 29, 2025 -

Wembley Stadiums Capital Summertime Ball 2025 Everything You Need To Know

Apr 29, 2025

Wembley Stadiums Capital Summertime Ball 2025 Everything You Need To Know

Apr 29, 2025 -

Recent Geary County Jail Bookings April 24 28 See Mugshots Here

Apr 29, 2025

Recent Geary County Jail Bookings April 24 28 See Mugshots Here

Apr 29, 2025