Manufacturing In America: Obstacles And Opportunities

Table of Contents

Obstacles Facing American Manufacturing

American manufacturers face a complex web of challenges that impact their competitiveness and growth. Let's examine some key obstacles:

Rising Labor Costs and Competition

Higher wages in the US compared to many other countries significantly impact the cost-competitiveness of American-made goods. This, coupled with the rise of automation and offshoring, has led to job displacement in certain sectors.

- Impact: Increased manufacturing costs make US products less price-competitive in the global market, leading to reduced exports and potential job losses.

- Competition: Countries like China, Vietnam, and Mexico offer significantly lower labor costs, attracting manufacturing investments away from the US.

- Examples: The textile and apparel industries have experienced significant job losses due to offshoring, while the automotive sector faces intense competition from foreign manufacturers.

- Statistics: While precise figures vary depending on the source and timeframe, reports consistently show a decline in manufacturing jobs in the US over the past few decades, although this trend has shown some recent signs of slowing.

Supply Chain Disruptions and Dependence on Foreign Sources

The COVID-19 pandemic starkly revealed the vulnerability of US manufacturers to global supply chain disruptions. Over-reliance on foreign sources for raw materials and components creates significant risks.

- Vulnerability: Disruptions like pandemics, geopolitical instability, or natural disasters in other countries can severely impact production in the US.

- Foreign Dependence: Many American manufacturers rely on imported components, creating a bottleneck in production if supply chains are interrupted.

- Examples: The semiconductor shortage of 2020-2021 demonstrated the critical dependence on foreign chip manufacturers and severely impacted various industries.

- Solutions: Reshoring and nearshoring initiatives are gaining traction, aiming to diversify supply chains and reduce dependence on single sourcing.

Regulatory Hurdles and Bureaucracy

Environmental regulations, labor laws, and other government regulations, while essential, can pose significant challenges to manufacturers. Excessive bureaucracy adds to compliance costs and slows down operations.

- Regulations: Compliance with environmental regulations (e.g., emissions standards) and labor laws (e.g., safety regulations) can be costly and complex.

- Bureaucracy: Navigating permits, licenses, and other bureaucratic processes can be time-consuming and inefficient.

- Examples: Stringent environmental regulations can increase production costs, particularly for energy-intensive industries.

- Streamlining: Government initiatives to streamline regulatory processes and provide clearer guidelines can help alleviate these challenges.

Skills Gap and Lack of Skilled Workforce

A significant skills gap exists in the American manufacturing sector. The lack of skilled workers hinders innovation, productivity, and competitiveness.

- Shortage: Many manufacturing jobs require specialized skills in areas like robotics, automation, and advanced manufacturing techniques.

- Workforce Training: Investment in vocational training programs and apprenticeships is crucial to bridge the skills gap.

- Attracting Talent: Initiatives to attract young people to manufacturing careers, highlighting the technological advancements and high-skilled opportunities, are essential.

- Examples: Successful programs like those offered by community colleges and industry-sponsored apprenticeships demonstrate effective ways to train and retain skilled workers.

Opportunities for Growth in American Manufacturing

Despite the challenges, significant opportunities exist for growth and revitalization in the American manufacturing sector.

Reshoring and Nearshoring Initiatives

The trend of reshoring (bringing manufacturing back to the US) and nearshoring (moving manufacturing to nearby countries) offers numerous advantages.

- Benefits: Improved supply chain control, reduced transportation costs, and increased job creation in the US are key benefits.

- Government Incentives: Government programs offering tax breaks, grants, and other incentives encourage companies to reshore their operations.

- Examples: Several companies have successfully reshored manufacturing operations, demonstrating the feasibility and benefits of this approach.

Technological Advancements and Automation

Automation and advanced technologies are transforming manufacturing, improving efficiency and productivity.

- Automation: Robotics, AI, and 3D printing are enhancing production processes, reducing costs, and improving product quality.

- High-Skilled Jobs: Automation creates new job opportunities in areas like robotics engineering, software development, and data analytics.

- Examples: Companies successfully implementing automation technologies have seen significant improvements in productivity and competitiveness.

Focus on Sustainability and Green Manufacturing

The growing demand for environmentally friendly products and processes creates opportunities for American manufacturers.

- Sustainable Practices: Adopting sustainable manufacturing practices reduces environmental impact and enhances brand reputation.

- Green Certifications: Certifications like LEED (Leadership in Energy and Environmental Design) demonstrate commitment to sustainability.

- Government Incentives: Government programs support green manufacturing initiatives, offering incentives for adopting sustainable practices.

Government Support and Investment

Government policies and initiatives play a vital role in supporting and strengthening American manufacturing.

- Tax Incentives: Tax credits and deductions can reduce the cost of investment in new equipment, technology, and workforce training.

- Grants: Government grants provide funding for research and development, infrastructure improvements, and workforce development programs.

- Examples: The various programs offered by the Department of Commerce and other government agencies provide significant support for American manufacturers.

Securing the Future of Manufacturing in America

Addressing the obstacles and capitalizing on the opportunities discussed above are crucial for securing a strong future for Manufacturing in America. By investing in workforce development, embracing technological advancements, promoting sustainable practices, and leveraging government support, the US can revitalize its manufacturing sector, creating high-skilled jobs, enhancing national security, and bolstering economic growth. We urge you to learn more about American manufacturing by exploring resources from the Department of Commerce, the Manufacturing Institute, and other relevant organizations. Support American-made products and advocate for policies that foster a thriving manufacturing sector—the future of American prosperity depends on it.

Featured Posts

-

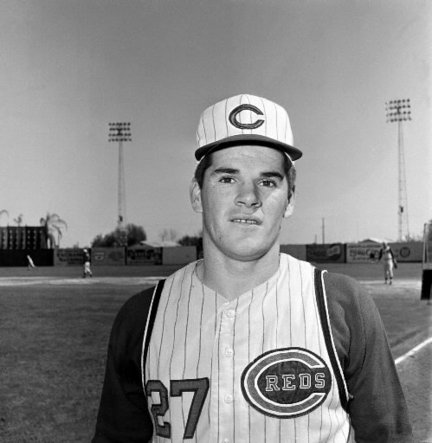

Pete Rose And The Presidential Pardon Understanding The Controversy

Apr 29, 2025

Pete Rose And The Presidential Pardon Understanding The Controversy

Apr 29, 2025 -

Ahtfalyt Fn Abwzby Tbda Fy 19 Nwfmbr

Apr 29, 2025

Ahtfalyt Fn Abwzby Tbda Fy 19 Nwfmbr

Apr 29, 2025 -

Investor Guide Navigating High Stock Market Valuations With Bof As Analysis

Apr 29, 2025

Investor Guide Navigating High Stock Market Valuations With Bof As Analysis

Apr 29, 2025 -

Exclusive University Group Defies Trump Administration Policies

Apr 29, 2025

Exclusive University Group Defies Trump Administration Policies

Apr 29, 2025 -

Us Shoppers Bear The Brunt How Trump Tariffs Inflate Temu Prices

Apr 29, 2025

Us Shoppers Bear The Brunt How Trump Tariffs Inflate Temu Prices

Apr 29, 2025

Latest Posts

-

Finding Nostalgia On You Tube Older Viewers Share Their Experiences

Apr 29, 2025

Finding Nostalgia On You Tube Older Viewers Share Their Experiences

Apr 29, 2025 -

Returning To Beloved Shows How You Tube Caters To Older Viewers

Apr 29, 2025

Returning To Beloved Shows How You Tube Caters To Older Viewers

Apr 29, 2025 -

London Real Estate Fraud British Court Upholds Vaticans Claim

Apr 29, 2025

London Real Estate Fraud British Court Upholds Vaticans Claim

Apr 29, 2025 -

Vatican Defrauded London Real Estate Deal Ruled Fraudulent By British Court

Apr 29, 2025

Vatican Defrauded London Real Estate Deal Ruled Fraudulent By British Court

Apr 29, 2025 -

Analyzing You Tubes Appeal To An Aging Viewership

Apr 29, 2025

Analyzing You Tubes Appeal To An Aging Viewership

Apr 29, 2025