US Crackdown Threatens Chinese Access To Iranian Plastics Materials

Table of Contents

The Scope of US Sanctions on Iranian Plastics Exports

The US has implemented a series of sanctions targeting Iran's petrochemical and plastics industries, significantly restricting the export of Iranian plastics materials. These sanctions, primarily enforced by the Office of Foreign Assets Control (OFAC) within the US Treasury Department, aim to pressure the Iranian government through economic means. Understanding the scope of these restrictions is crucial to grasping their impact on global trade.

-

Specific Sanctions: The sanctions encompass a range of restrictions, including limitations on the purchase, sale, and transportation of Iranian petrochemicals, including key plastics feedstocks like polyethylene and polypropylene. These sanctions often target specific companies and individuals involved in the Iranian petrochemical industry.

-

Enforcement and Penalties: OFAC actively monitors compliance with these sanctions. Penalties for violation can be severe, ranging from financial fines to criminal prosecution for US persons and entities, and secondary sanctions which can impact foreign businesses engaging in transactions with sanctioned Iranian entities. The penalties for non-compliance make firms cautious about sourcing Iranian materials.

-

Legal Framework: The legal framework underpinning these sanctions is complex, rooted in various US laws and executive orders aimed at combating terrorism, proliferation of weapons of mass destruction, and human rights abuses attributed to the Iranian government.

-

Historical Context: The US has maintained sanctions against Iran for decades, with periods of intensification and relaxation depending on diplomatic relations and Iran's actions. The current sanctions are a part of a broader strategic effort.

-

Impact on Global Energy Markets: The sanctions indirectly impact global energy markets by limiting Iran's ability to export its oil and gas, which are crucial feedstocks for petrochemical production worldwide. This scarcity can affect pricing and availability of plastics across the globe.

Impact on Chinese Plastics Manufacturing and Supply Chains

China's plastics industry has historically relied on Iranian plastics materials, which have been a cost-effective source of raw materials. The US sanctions have severely disrupted this established supply chain, creating significant challenges for Chinese manufacturers.

-

Sourcing Iranian Plastics: Many Chinese companies have long-standing relationships with Iranian petrochemical producers, purchasing significant quantities of various plastics materials for use in their manufacturing processes.

-

Dependence on Iranian Supplies: The extent of China's dependence on Iranian plastics is substantial, representing a significant portion of the raw material input for various sectors like packaging, construction, and consumer goods. Precise figures are difficult to obtain due to the opaque nature of some trade routes, but industry analysts estimate the dependency to be significant.

-

Immediate and Long-Term Effects: The sanctions have caused immediate price increases for plastics in China as alternative suppliers struggle to meet the increased demand. In the long term, the disruption may lead to higher production costs, reduced competitiveness, and potential shifts in the global plastics manufacturing landscape.

-

Increased Costs and Challenges: Finding suitable alternative suppliers, navigating complex logistics, and dealing with potential quality variations from new suppliers are among the major challenges faced by Chinese companies. Increased transportation costs and potential tariffs also contribute to the increased expenditure.

-

Mitigation Strategies: Chinese businesses are exploring various strategies to mitigate the impact of sanctions, including diversifying their suppliers, investing in domestic petrochemical production, and seeking alternative materials.

Seeking Alternative Suppliers: A Difficult Path

Finding suitable replacements for Iranian plastics is proving to be a complex task. While other countries produce similar materials, switching suppliers presents significant challenges.

-

Challenges in Finding Alternatives: The quality, pricing, and reliability of alternative suppliers may differ significantly. Ensuring a consistent supply chain requires thorough due diligence.

-

Price Implications: Switching to alternative suppliers often comes with higher prices, increasing production costs and potentially impacting the competitiveness of Chinese-made products in the global market.

-

Geopolitical Risks: Relying on alternative suppliers in other regions may introduce new geopolitical risks and dependencies, exposing businesses to new potential disruptions and uncertainties.

-

Increased Prices of Plastics Globally: The decreased availability of Iranian plastics has contributed to the upward pressure on global plastics prices, creating a ripple effect throughout the plastics industry.

Geopolitical Implications and Future Outlook

The US sanctions on Iranian plastics exports have significant geopolitical ramifications, impacting the relationships between the US, China, and Iran, and shaping the future of the global plastics industry.

-

US-China-Iran Relations: The sanctions further strain US-China relations, as China seeks to maintain trade with Iran despite the US restrictions. This situation adds another layer of complexity to the already strained geopolitical landscape.

-

Economic Impact on Iran: The sanctions severely impact Iran's economy, hindering its ability to export vital goods and reducing its revenue streams.

-

Future of the Chinese Plastics Industry: The Chinese plastics industry is undergoing a significant transformation, driven by the need to diversify its supply chains and adapt to the geopolitical realities of the situation. This transformation may lead to increased investment in domestic production and innovation.

-

Changes in Global Trade Patterns: The sanctions may lead to the reshaping of global trade patterns, with new alliances and supply chains emerging as businesses adapt to the changing geopolitical context.

Conclusion

The US crackdown on Iranian plastics exports presents a significant hurdle for Chinese manufacturers heavily reliant on Iranian supplies. The sanctions create supply chain disruptions, drive up costs, and force businesses to adapt and find alternative suppliers. This situation highlights the complex interplay between geopolitical tensions and global trade, impacting not just the plastics industry, but also wider economic and political landscapes.

Call to Action: Understanding the intricacies of the US sanctions on Iranian plastics is crucial for businesses operating in the global plastics market. Staying informed on the evolving situation, researching alternative supply chains, and developing adaptable sourcing strategies are vital for ensuring a stable and resilient business model in the face of these trade restrictions. Proactive risk management and a flexible approach to sourcing Iranian plastics materials are paramount for navigating this challenging environment.

Featured Posts

-

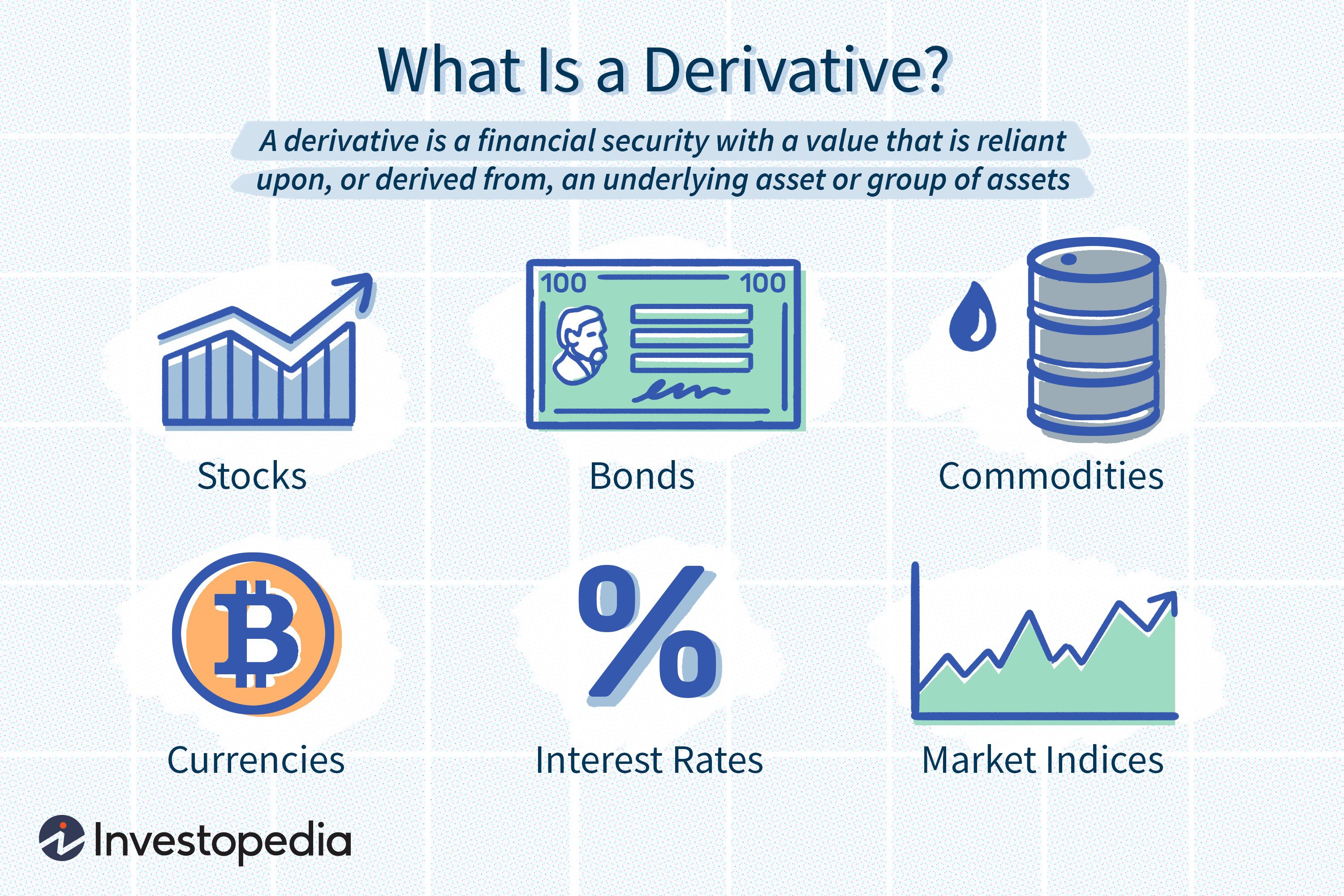

Xrps Uncertain Future A Look At The Derivatives Market

May 07, 2025

Xrps Uncertain Future A Look At The Derivatives Market

May 07, 2025 -

Who Wants To Be A Millionaire Celebrity Special Behind The Scenes Look At The Popular Show

May 07, 2025

Who Wants To Be A Millionaire Celebrity Special Behind The Scenes Look At The Popular Show

May 07, 2025 -

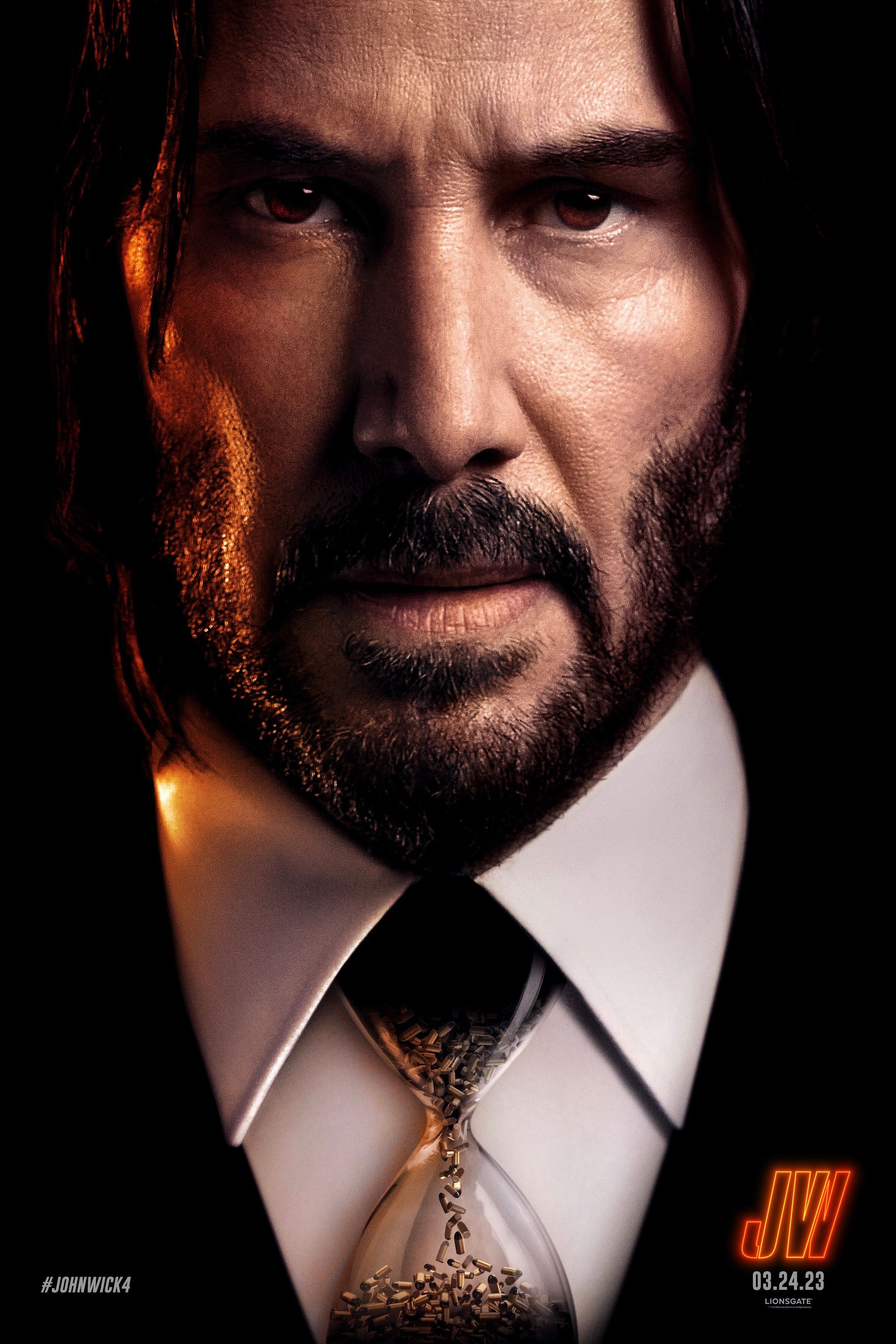

John Wick Franchise Why Chapter 3 Has The Lowest Rotten Tomatoes Score

May 07, 2025

John Wick Franchise Why Chapter 3 Has The Lowest Rotten Tomatoes Score

May 07, 2025 -

Chinese Stocks Surge Following Us Talks And Economic Data Release

May 07, 2025

Chinese Stocks Surge Following Us Talks And Economic Data Release

May 07, 2025 -

John Wick 5 Reimagining Johns Next Mission After The High Table

May 07, 2025

John Wick 5 Reimagining Johns Next Mission After The High Table

May 07, 2025

Latest Posts

-

De Andre Hopkins Joins Baltimore Ravens Contract Breakdown And Impact

May 08, 2025

De Andre Hopkins Joins Baltimore Ravens Contract Breakdown And Impact

May 08, 2025 -

Nc State Loses Kendrick Raphael Rising Junior Running Back Decommits

May 08, 2025

Nc State Loses Kendrick Raphael Rising Junior Running Back Decommits

May 08, 2025 -

Nfl News Browns Sign Experienced Wide Receiver And Return Specialist

May 08, 2025

Nfl News Browns Sign Experienced Wide Receiver And Return Specialist

May 08, 2025 -

Jokic I Dzordan Tradicija Tri Poljupca I Uloga Bobija Marjanovica

May 08, 2025

Jokic I Dzordan Tradicija Tri Poljupca I Uloga Bobija Marjanovica

May 08, 2025 -

Westbrook Leads Nuggets In Birthday Song For Jokic

May 08, 2025

Westbrook Leads Nuggets In Birthday Song For Jokic

May 08, 2025